Rheology is a powerful tool for anyone looking to understand how materials behave under different conditions and can provide valuable insights into their structural and textural properties. This study demonstrates the application of rheology to whipping cream, showcasing how variations in whipping time can influence the material’s behaviour.

Understanding how plant-based creams perform when whipping is essential for creating products that replicate the texture and stability of conventional dairy creams, as the market for plant-based substitutes continues to increase.

Exploring the Dynamics of Cream Texture and Stability

Creams are a staple in many culinary applications, varying in fat content and texture. From light, pourable creams, to thick, whipping creams, their behaviour under various conditions can greatly affect their final form.

Whipping is an example of a high shear rate process, which is characterised by rapid deformation or flow, typically caused by high movement or high stress. To investigate how whipping cream responds to these conditions, we measured its complex modulus using an oscillatory stress sweep test. An oscillatory stress sweep utilises a rheometer to apply increasing stress to a material and monitor the changes in the material’s modulus, in this case, the complex modulus. The complex modulus (G*) is a measure of a material’s overall resistance to deformation and is a critical parameter for understanding the viscoelastic behaviour of materials. It combines 2 components:

- Storage Modulus (G’) – This represents the elastic (solid-like) properties

- Loss Modulus (G”) – This represents the viscous (liquid-like) properties

Impact of Whipping Duration on Dairy Cream

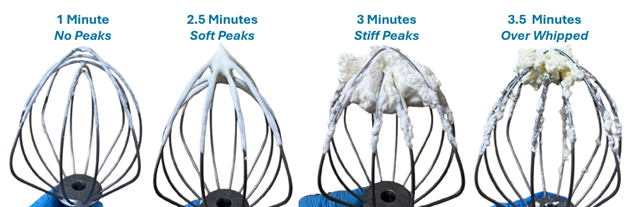

A dairy whipping cream sample was subjected to whipping for 1, 2.5, 3, and 3.5 minutes to assess the impact on its structural and textural properties. Small air bubbles are introduced and trapped within the mixture when the cream is whipped, going through four distinct stages as shown in Figure 1.

- 1 Minute – No peaks are observed; the cream is thickened slightly, however, it still flows freely and does not hold shape.

- 2.5 Minutes – Soft peaks can be observed; the cream is thick enough to hold its shape briefly, however the peaks immediately drop when the whisk is lifted.

- 3 Minutes – Stiff peaks are observed; the cream is fully whipped, and the peaks hold their shape firmly and do not collapse when lifted.

- 3.5 Minutes – It is clear the cream has been over-whipped as the cream has developed a grainy texture, losing its smooth consistency and indicating the onset of butter formation.

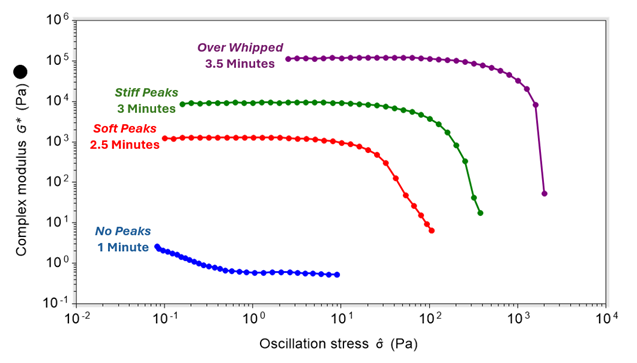

A simple way to compare the structure of creams is by using an oscillatory stress sweep to capture complex modulus data at different whipping times.

Oscillatory Stress Sweep

The results show that an increase in whipping time causes an increased complex modulus, reflecting the incorporation of air into the cream and resulting in stable foam formation.

- 1 Minute (No Peaks Observed) – The lowest complex modulus among all samples. This means that the material resists deformation less effectively, suggesting that the cream is exhibiting predominantly liquid-like behaviour.

- 3.5 Minutes (Over-Whipped) – The highest complex modulus among all samples, representing the transition to solid-like behaviour and butter formation. The excessive whipping causes the dispersed fat phase to coalesce, breaking down the emulsion and foam structure, leading to phase separation as the interfaces break down.

Classic Yielding Behaviour

For whipping times of 2.5, 3, and 3.5 minutes, the complex modulus maintains a steady value over the range of stress values, indicating that the cream retains its structure. However, when subjected to higher stress levels, the complex modulus shows a rapid decline, indicating that the cream has surpassed its yield point. This signifies the onset of structural breakdown as air bubbles collapse and the foam is destabilised, leading to permanent deformation and represents the transition to more liquid-like behaviour. This is an example of classic yielding behaviour seen in many materials. The complex modulus plateaus over a range of stress values; however, as the stress exceeds the yield point, the complex modulus suddenly declines.

Summary

At the Centre for Industrial Rheology, we can utilise oscillatory stress sweep testing to gain valuable insights into the structural and textural properties of materials such as whipping creams. These techniques provide a comprehensive understanding of how conditions such as whipping duration and increased stress influence these properties.

Suppose you are looking to identify key interfacial behaviours of your creams that help understand emulsion or foam creation, and stability. In that case, we have a variety of material characterisation techniques to help you uncover these insights. These include utilising interfacial rheology, where instead of looking at the bulk phase with an oscillation stress sweep, we can look at the liquid/liquid interface in an emulsion, or a gas/liquid interface in a foam, and evaluate the viscoelastic moduli.

In addition to this, we can use drop shape analysis for surface tension and contact angle measurements, which influence foam formation, stability, and adhesion to surfaces. When testing creams, interfacial characterisation can be complementary to rheological testing. By integrating these advanced rheological techniques, data collected can be utilised to refine product formulations to meet specific texture and stability requirements.

For more details about this and our other testing services, please contact us.