The succulence of food is described as the quality of being tender, juicy, and tasty. It’s a common term you may use whenever you encounter food that hits the spot. However, it is more than just a sensory delight, it is arguably one of the most important factors in what makes a specific food stand out from others. There is increased significance in investigating succulence, particularly as plant-based meat alternatives often lack the succulence of traditional meat products.

Quantifying succulence

One way to quantify the succulence of food is to utilise tribology to investigate the coefficient of friction. Tribology is the study of friction, lubrication, and wear of interacting surfaces. Traditionally, tribology is employed to study hard surfaces, such as those found in machines, engines, and gears. However, tribology also extends into further branches, such as biotribology and soft-tribology. Biotribology concerns the study of friction, lubrication, and wear in biological systems, such as in joints and on the surface of the eye. Soft-tribology measurements quantify friction between two compliant surfaces that can be employed as analogues for physiological surfaces. As such, soft tribology is employed in this study to investigate the succulence of different types of meats and their plant-based alternatives.

Two studies were conducted: An assessment of the lubricity of a variety of meat and plant-based alternative slices, and a tribological comparison of a range of beef and plant-based burgers.

Measuring the lubricity of animal-derived and plant-based meats

The lubricity of various meat slices and vegan alternatives was investigated. Lubricity is a measure of a substance’s ability to reduce friction. In the context of meat slices, lubricity serves as an indicator of their succulence.

A high-performance rheometer was employed as the measurement platform for the testing. Slices of each product were cut to the same geometric size using a template and situated on a silicone base. The temperature at the silicone surface was set at 37℃. The torque was measured at a single rotational speed under a defined load force using a custom measuring system. Lubricity was then calculated as the reciprocal of the torque over the load force.

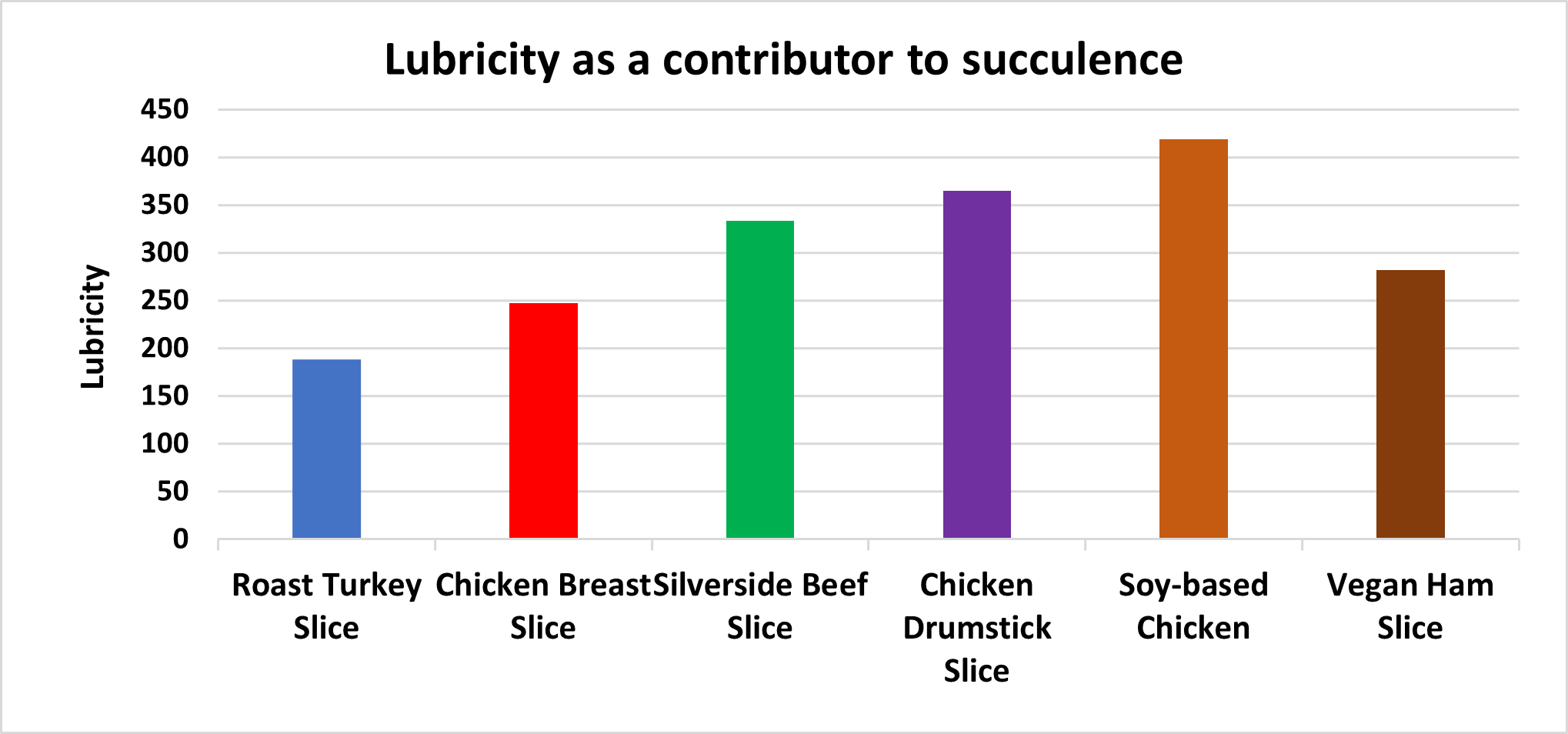

The resulting lubricity values are compared in Figure 1.

The results demonstrate a wide range of lubricities across the samples with the turkey showing the lowest and the soy-based chicken the highest.

One of the most common criticisms of turkey, particularly during festive meals, is its dryness. The results show that turkey has the lowest lubricity across the products tested. The lower lubricity of turkey provides a scientific explanation as to why turkey is subject to such common complaints. Without sufficient natural lubrication, turkey meat dries out quickly, unless special cooking techniques such as brining or basting are utilised.

Fats and oils in food typically serve as a lubricant, causing a reduction in friction and thus resulting in the meat being more succulent. Chicken thigh typically contains around three times as much fat as chicken breast, leading to their greater succulence. This difference is demonstrated in the results by the approximately 36% greater lubricity of the chicken drumstick versus the breast.

Interestingly, the soy-based chicken substitute demonstrated the highest lubricity across the products tested. At first glance, this seems intriguing as plant-based meats are often associated with a lack of succulence, however, the high proportion of added coconut and rapeseed oil added to the soy matrix may explain the result.

Tribology measurements for burger succulence

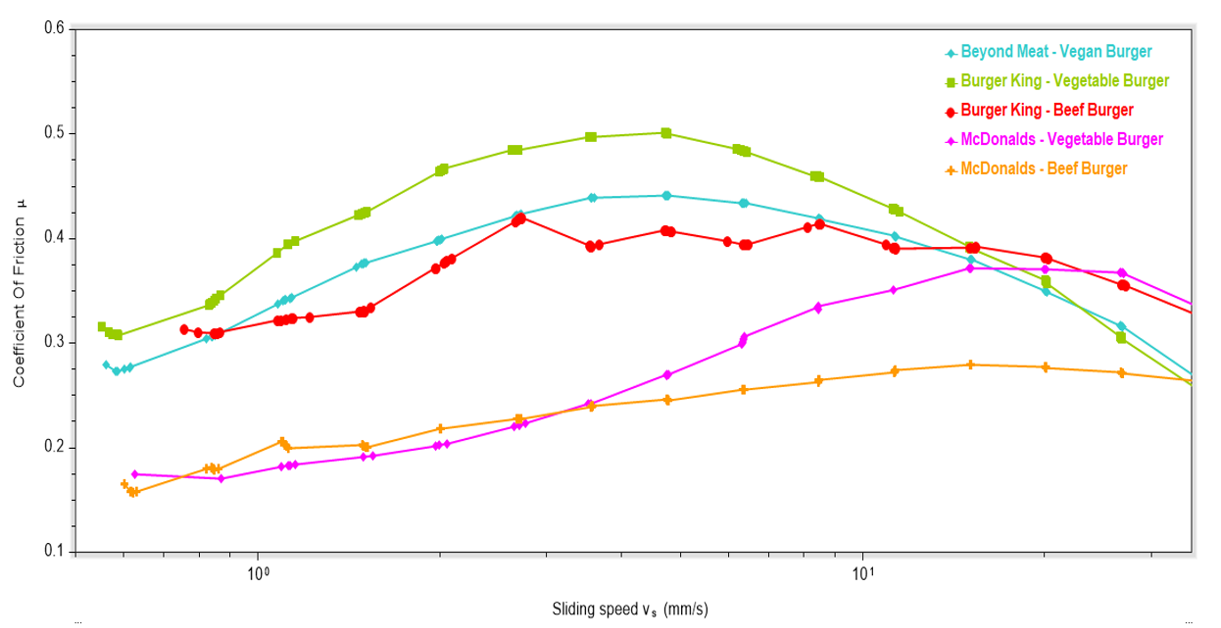

Six burgers were tested in this study, including McDonald’s beef and vegetable burgers, Burger King beef and vegetable burgers, and Beyond Meat’s vegan burger. This allows a comparison of the succulence between these market leaders and can be used as a benchmark for achieving similar succulence with new plant-based alternatives being brought to market.

To quantify the succulence of the burgers, a rheometer utilising a custom-built “three balls on silicone plate” measuring system was used to carry out assessments of the lubricating ability of each burger’s “juice” fraction. The burgers were collected as cooked and served from the restaurants. The liquid portions of the patties were extracted by pureeing the burgers with water and centrifuging the mixture. The supernatant “juice” was then collected for measurement.

This graph shows how the coefficient of friction changes with an increase in sliding speed for the different types of burgers. The McDonald’s beef burger has the lowest coefficient of friction across the range of sliding speeds. Generally, the McDonald’s beef burger is seen as the market benchmark, and competitors in the market aim to reach a succulence similar to the McDonald’s beef burger. This suggests that the low coefficient of friction is a potential major contributor to its succulence.

Principal Component Analysis

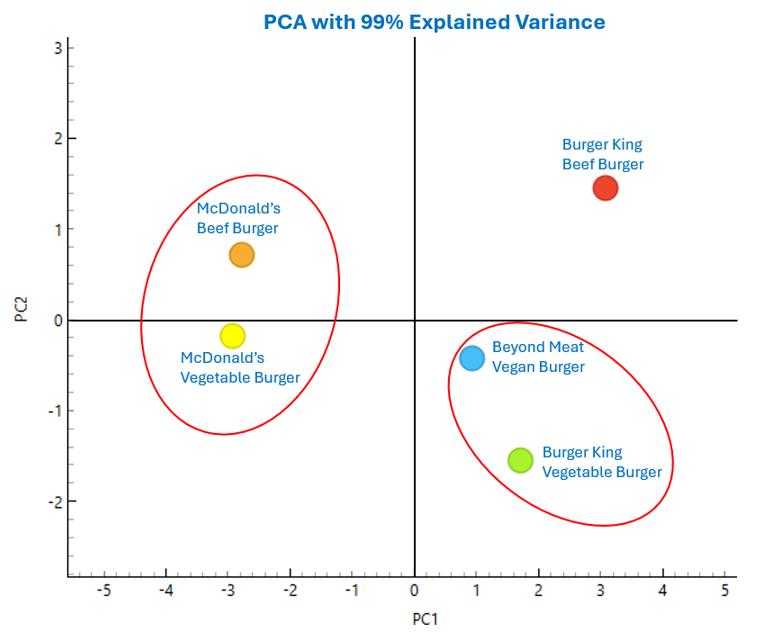

Principal component analysis (PCA) was performed on the burger tribology dataset to obtain the plot in figure 2.

PCA is a great tool that allows you to assess the similarity of a product to identify positive or negative benchmarks on the market. Principal component analysis reduces large data sets into principal components that retain the most possible original information. These principal components are linear combinations of the original variables that have the maximum variance compared to other linear combinations. PC1 is the direction in space along which the data points have the most variance. PC2 is the direction in space that has the next highest variance and is uncorrelated with PC1. Put simply, PCA can be thought to twist and turn a multi-dimensional data set until the shadow it projects onto a two-dimensional surface delivers the most information.

PCA works best with large data sets. However, with the limited dataset of this study, the plot suggests the McDonald’s beef and vegetable burgers exhibit similar lubrication behaviour and the Beyond Meat vegan burger and the Burger King vegetable burger also exhibit similarities. It is shown that the Burger King beef burger has the largest variation, suggesting a more unique succulence profile compared to its counterparts.

Summary

In this study we were able to conduct rapid screening to compare the lubricity of different meat slices and compare the coefficient of friction of different burgers, to investigate succulence.

Through principal component analysis, we were able to visualise the similarities and differences between different burgers, allowing quick comparisons to benchmarks on the market. This provides essential information to anyone who is developing plant-based alternatives to meat-based products and wants to ensure their product retains the succulence found in meat-based products.

It must be noted that lubrication will change as a product cools and fats crystallise. Tests can be performed over a range of temperatures to model lubrication as a function of temperature. This could prove a valuable tool for researchers developing products that retain succulence, for example, following lengthy food delivery times. In a similar vein, thermorheological profiling, such as that employed in this article comparing animal and plant oils, can add additional insights for companies aiming to bring market leading plant-based products to the market.

We offer all the tests in this case study and more

Contact us today to discuss how we can help