Rheological characterisation of greases is essential for understanding their performance and reliability under demanding conditions.

Rheological characterisation of greases is essential for understanding their performance and reliability under demanding conditions.

This article explores the rheological properties of greases, characterising them under both freshly dispensed conditions and after prolonged thermal ageing.

Additionally, we introduce the innovative use of rheo-impedance spectroscopy as a complementary technique to traditional rheology, enabling a deeper understanding of microstructural changes that occur.

Impedance spectroscopy is a widely used technique for probing the microstructure of a sample, with rheo-impedance spectroscopy adding the value of allowing these measurements to be done under varying shear and temperature conditions.

The Structure of Greases

Structurally, greases consist of a thickening agent dispersed within a lubricating base oil. The base oils commonly used include mineral oils and synthetic oils, with thickeners such as lithium soaps, calcium soaps, and clays, to name a few. Different greases are specialised to work for specific applications. For example, lithium-complex greases are used in applications where temperature stability is essential, whereas calcium-based greases are used where enhanced water resistance may be necessary.

In this study, we focus specifically on LM47 grease manufactured by LIQUI MOLY. LM47 consists of a mineral base oil with lithium soap thickener enhanced with molybdenum disulfide (MoS₂), designed for “high-performance lubrication in demanding conditions”. It boasts “outstanding lubricity and long-lasting performance” with an operational temperature range of -30°C to 120°C.

To evaluate the bold claims of this grease and examine its structural properties, we compared the grease when it was freshly dispensed to another sample of the grease that had been subject to thermal ageing at 120°C for five days. The grease was not left sealed in our ageing environment to allow potential oxidation effects to occur. This approach aimed to determine if thermal ageing induces significant changes in the grease’s rheological behaviour and overall structure.

Rheological Characterisation of Greases

Complex Viscosity

Greases can present a challenge for viscosity testing due to their complex and structured nature. Oscillatory measurements overcome this challenge and are a valuable tool in rheological analysis. We can conduct an oscillatory temperature sweep to allow us to observe how a grease’s rheological properties evolve with temperature. One of the metrics obtained from this technique is the complex viscosity, which reflects a material’s resistance to deformation under oscillatory conditions.

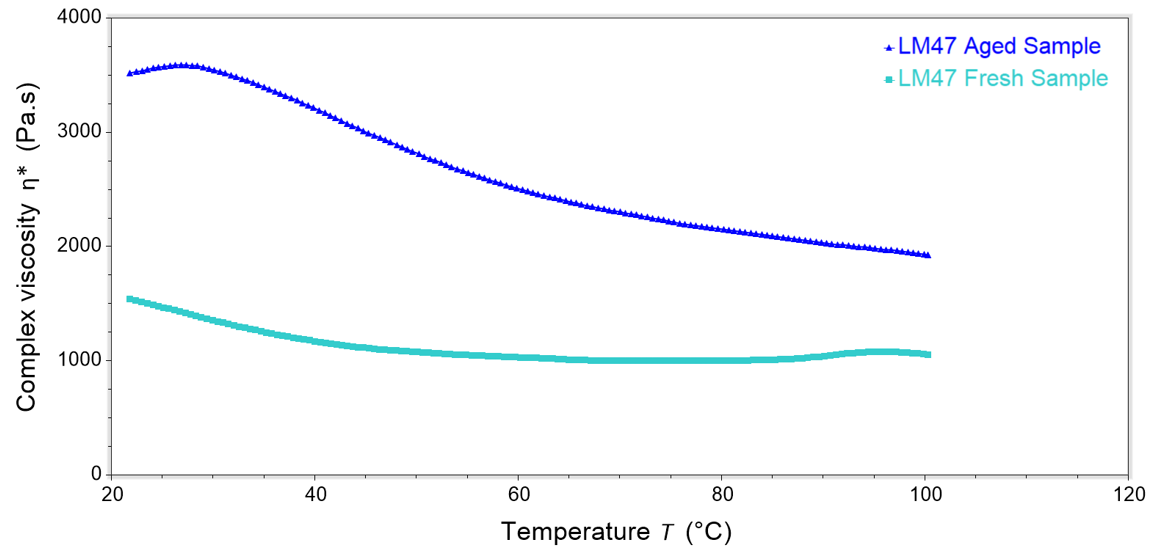

Figure 1 shows how the complex viscosity of the grease changes with temperature for the fresh and aged grease. The aged grease exhibits a significantly higher viscosity compared to the fresh grease. A plausible explanation for this is oxidation occurring during ageing in addition to thermal degradation. Generally, greases are formulated for excellent oxidation resistance, so it is interesting to see potential oxidation effects, especially as the thermal ageing carried out was within the operational temperature range listed for the grease. At higher temperatures, the aged grease does begin to decrease in viscosity, however, it still maintains a higher viscosity over the temperature range tested when compared to the fresh grease.

Phase Angle

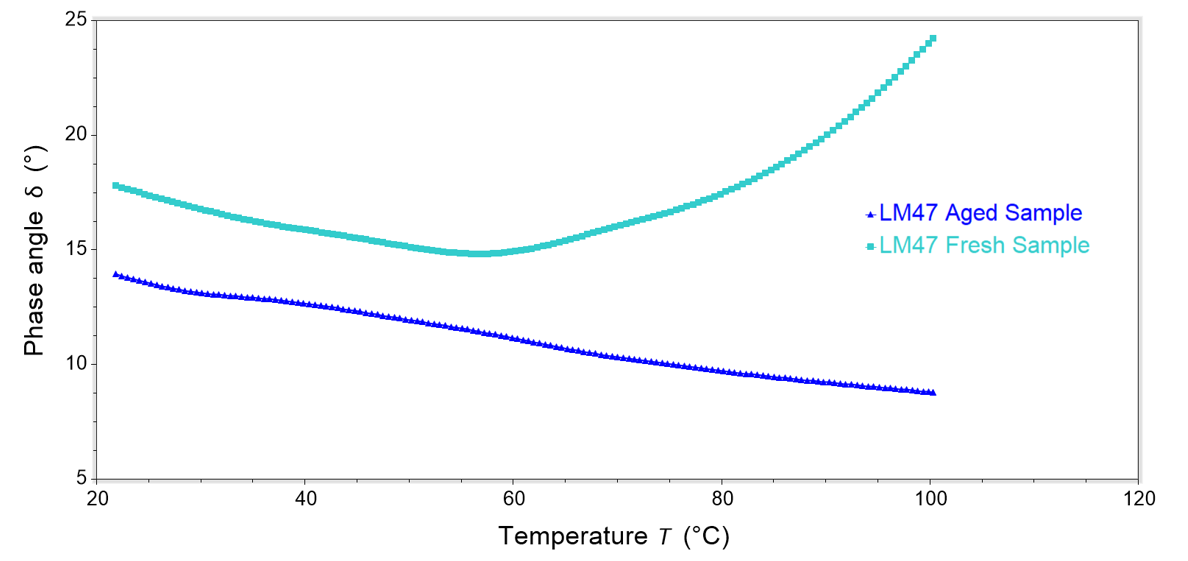

To obtain deeper insights into the specific elastic and viscous behaviours of the sample, we can look at how the phase angle changes with temperature. A phase angle of 90° indicates purely liquid-like behaviour, whereas 0° indicates purely solid-like behaviour, which can be interpreted as an elastic response, typically arising from an interconnected microstructure within the material.

For the fresh grease, the relationship between phase angle and temperature reveals a complex thermal response. Specifically, and counterintuitively, between temperatures of 20°C and 60°C, the phase angle decreases, indicating that the sample is transitioning to more solid-like behaviour, suggesting a developing structure. Beyond 60°C, the phase angle starts to increase more expectedly, suggesting that the material is becoming more liquid-like in its behaviour.

In contrast, the aged grease consistently exhibits a lower phase angle compared to the fresh grease, with the phase angle decreasing with increasing temperature. This decrease indicates a continued transition to more “solid-like” behaviour, clearly demonstrating the impact of potential oxidation on the grease’s thermal characteristics.

Rheo-Impedance Spectroscopy on Greases

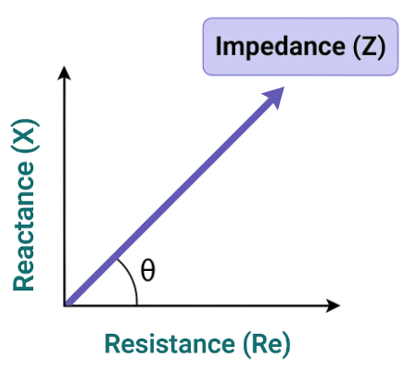

Beyond these essential rheological metrics, rheo-impedance spectroscopy offers advanced microstructural insights by allowing impedance measurements to be taken under dynamic shear and temperature conditions. It works by applying a small alternating current through a sample to obtain its impedance, which is the overall opposition to an electrical current.

Impedance can be split into resistance and reactance, as shown by Figure 3, which are the key metrics used to understand the microstructure of a sample.

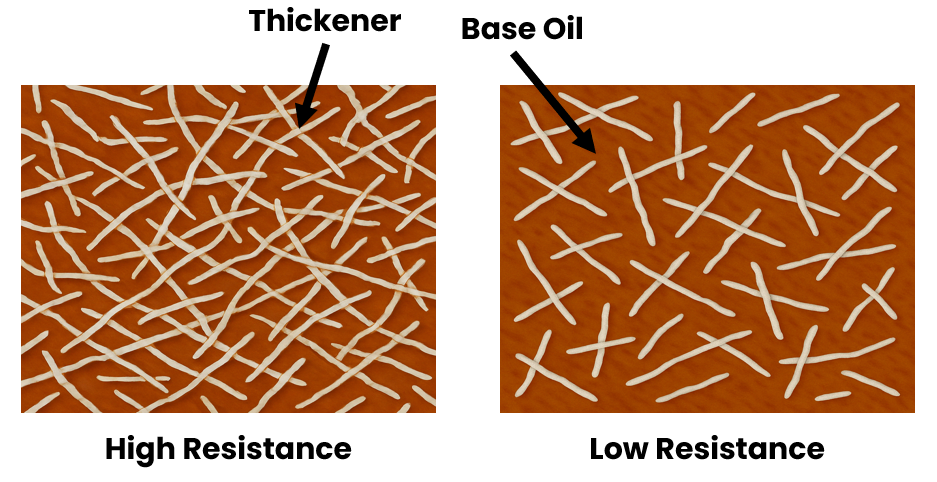

Resistance represents the in-phase component of the response, describing the opposition offered to both alternating and direct current. A sample with more restricted conductive pathways will result in a higher resistance, and as such, resistance reflects the degree of structure in a sample.

Reactance represents the part of impedance that is out-of-phase with the current, reflecting the additional opposition offered to alternating current only, where capacitance is present. Capacitance arises from a sample’s ability to store charge temporarily, and as such, reactance data can reveal the extent and integrity of interfaces within a sample.

Temperature Effects on Impedance Spectroscopy

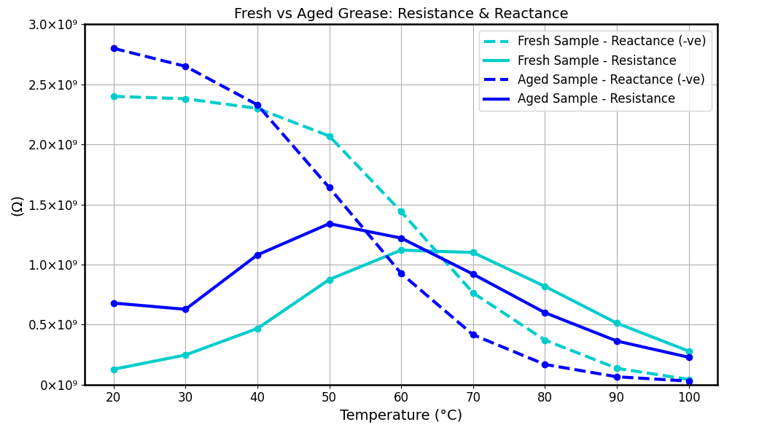

Typically, data from impedance spectroscopy is represented through a Nyquist or Bode plot due to a dielectric frequency dependence on impedance. We have extracted the resistance and reactance values at 10Hz and plotted them against temperature to obtain a simpler visual to look at how both values are changing with temperature.

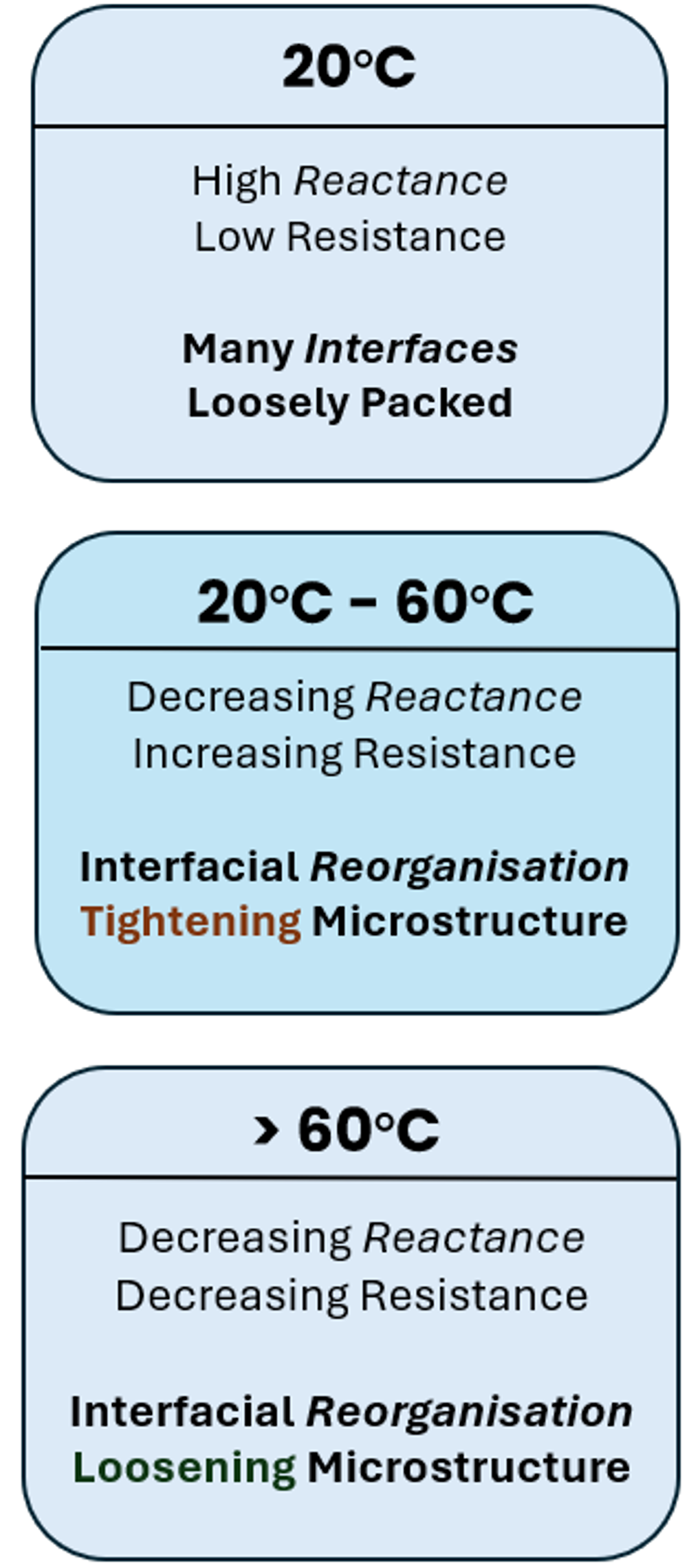

At 20°C, both greases exhibit a large reactance, indicating high capacitance, suggesting the presence of many interfaces between the grease’s thickener and base oil. However, the comparatively lower resistance value at this temperature suggests that while the internal interfaces are abundant, the overall microstructure of the grease is relatively loosely arranged.

At 20°C, both greases exhibit a large reactance, indicating high capacitance, suggesting the presence of many interfaces between the grease’s thickener and base oil. However, the comparatively lower resistance value at this temperature suggests that while the internal interfaces are abundant, the overall microstructure of the grease is relatively loosely arranged.

As temperature increases towards 60°C, resistance begins to rise, representing increased opposition to current, suggesting that the microstructure of the grease is tightening. Conversely, reactance is decreasing, suggesting that the interfaces are becoming less effective at storing charge. Microstructurally, this suggests that the interfaces are experiencing a change in organisation, or even perhaps slight thermal degradation.

Above 60°C, resistance declines, suggesting the microstructure is becoming less compact. These changes suggest that although the grease undergoes microstructural compaction between 20°C and 60°C, higher temperatures cause the structure to weaken, leading to a less compact microstructure with rearranged interfaces.

There are distinct differences in impedance spectra between the fresh and aged grease samples. Although both samples follow the same shape and trend, the aged sample undergoes changes at lower temperatures compared to the fresh grease, suggesting that ageing results in a decrease in thermal performance.

Additionally, at lower temperatures, the aged grease exhibits a higher resistance and reactance compared to the fresh grease. However, at elevated temperatures, resistance and reactance decrease more significantly compared to the fresh grease. These pronounced changes could be suggesting subtle microstructural differences that we are not seeing with rheology alone, providing insights into the impact of thermal ageing and potential oxidation on the grease’s microstructure.

Summary

The combination of Rheo-IS with traditional rheological methods provides comprehensive material insights, extending beyond insights into viscoelastic properties. By assessing resistance and reactance, Rheo-IS effectively tracks detailed changes in the extent and integrity of interfaces and the compactness of the grease structure. Ultimately, these combined analytical techniques paint a detailed picture of how the microstructure of greases can evolve with changing temperatures and highlights the sensitivity of Rheo-IS in detecting subtle microstructural changes.

In addition to its use in probing the microstructure of samples, Rheo-IS can be used to investigate dielectric properties, such as relative permittivity and the dissipation factor, of a sample under varying shear and temperature conditions. See our case study investigating dielectric greases, where we compared multiple greases at fresh and thermally aged conditions to see if ageing impacted their dielectric properties.

Rheo-IS is a very new technique for us, and we are actively exploring its uses and interpretations. If you think this technique can offer value to your product, do not hesitate to contact us, and we can set up a chat around this technique.