Soft tribology is becoming increasingly established as a method for obtaining quantified, objective and repeatable predictions of lubricity. Along with viscosity, lubricity has been identified as a key contributor to the mouthfeel of foods and drinks. This study explores the use of soft tribology to quantify and compare the lubrication provided by three popular lozenges marketed for soothing sore throats.

The Role of Lozenges in Soothing Throat Discomfort

Throat lozenges are small, medicated tablets containing both active and inactive ingredients. The active ingredients provide topical effects such as antiseptic or pain-relieving properties, and the inactive ingredients lubricate and soothe irritated throat tissues.

When a lozenge is placed in the mouth it dissolves slowly, releasing ingredients to suppress any coughs and reduce throat irritation temporarily. This slow dissolution is purposely designed to release ingredients over time to provide sustained relief. Lozenges contribute significantly to providing instant relief and a reduction in symptoms; however, they do not cure throat infections or coughs.

There are many lozenge brands on the market, which all aim to provide alleviation from throat discomfort. Although they have the same aim, they can vary greatly in composition.

Understanding Lozenge Lubrication Through Soft Tribology

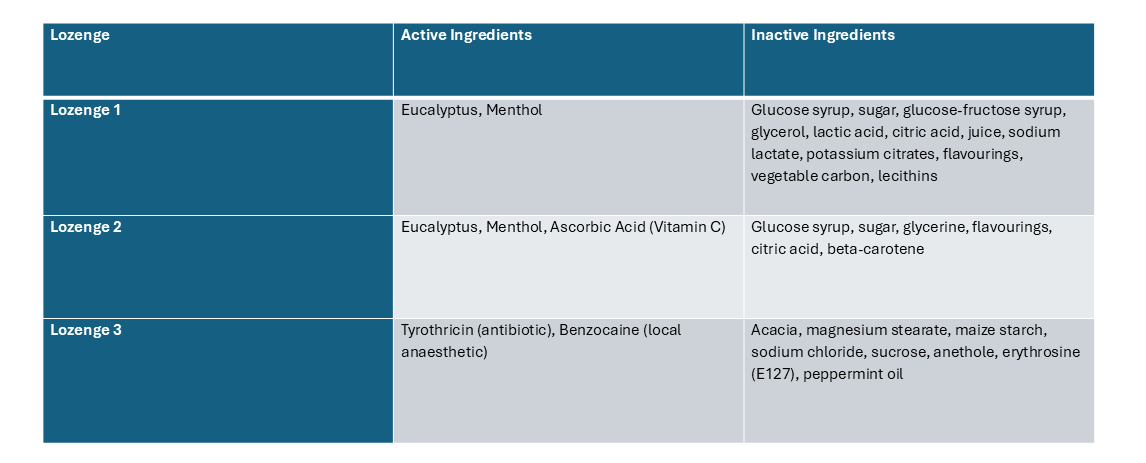

The soft tribology methods we offer at the Centre for Industrial Rheology can measure the coefficient of friction as a function of sliding speed, providing an indicator of the effectiveness of the lozenge in lubricating irritated throat tissues, hence reducing symptoms. We tested three lozenges with differing components listed in Table 1, with the inactive ingredients that may affect lubricity highlighted.

Sample solutions were prepared by dissolving lozenge material in an equal weight of deionised water. A rheometer utilising a custom-built “three balls on silicone plate” measuring system was used to carry out measurements at 37°C under a defined load.

Tribological Fingerprints

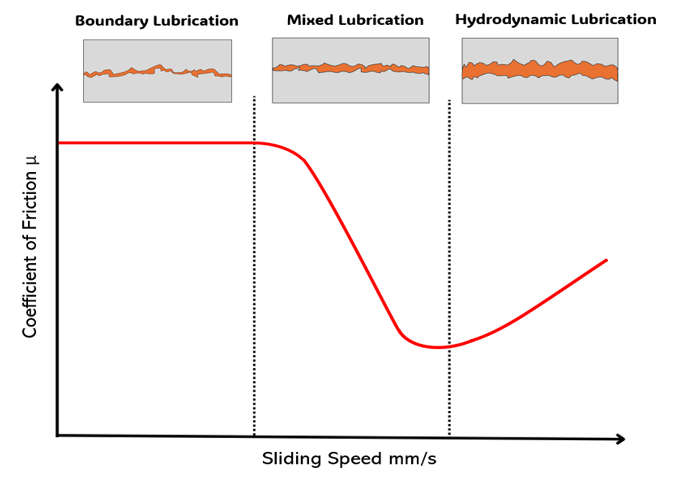

A lower coefficient of friction represents better lubrication of the measurement surfaces by the dissolved lozenge, suggesting improved lubrication on irritated throat tissues. While performing soft tribology measurements, the curves produced often correlate to regions on a Stribeck curve as seen in Figure 1.

In a tribo-contact situation, at low sliding speeds, the interaction between surfaces is dominated by direct contact between surface asperities (the peaks and troughs on the contacting surfaces) which results in high friction. This is the result of not enough lubricant pressure to create a stable separating film to support the applied load, signifying the boundary lubrication regime. As the sliding speed increases, more lubricant is entrained between the surfaces, resulting in hydrodynamic lift. This lift leads to partial separation of the surfaces and a subsequent decrease of friction, a feature of the mixed lubrication regime. As sliding speed is increased further, sufficient hydrodynamic lift is generated to completely separate the surfaces, and the hydrodynamic lubrication regime ensues. This transition is signified by the point where the coefficient of friction reaches its lowest value, with the subsequent increase at higher sliding speeds being due to viscous drag.

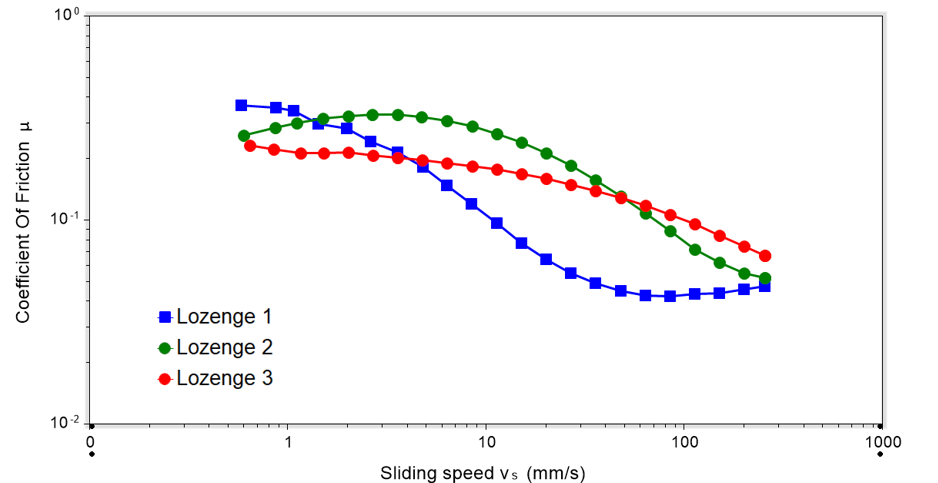

The boundary lubrication regime and mixed lubrication regime are apparent among all samples in Figure 2. Although the hydrodynamic lubrication regime is not evident among all samples, lozenge 1 shows a slight increase in friction at high sliding speeds, indicating the onset of hydrodynamic lubrication. The results indicate that lozenge 1 offers significantly better lubrication across the range of sliding speeds, however, it is important to look at the sliding speeds that would be relevant to swallowing the dissolved lozenge in the mouth.

A study looking at the speed of tongue movement during swallowing revealed an average speed of 10.34 mm/s [1]. Although this is not the speed at which the dissolved lozenge will experience during swallowing, we can use this value to identify the general region on the graph that is crucial for this application. From our results, we can see that around this sliding speed, lozenge 1 exhibits the highest lubricity values out of all the samples, indicating that it is the most effective lozenge.

Summary

At the Centre for Industrial Rheology, we can utilise our soft tribology methods to conduct rapid lubricity measurements to provide valuable insights into the mouthfeel and lubricity of products such as lozenges. By measuring the coefficient of friction as a function of sliding speeds, a Stribeck curve can be used as a tribological fingerprint of a sample. When soft tribology methods are exploited with rheological methods, the data collected can assist in determining which combination of physical properties could be utilised to target a certain set of attributes.

To find out more, read our case study on tribo-rheology for skincare, where we showcase the use of soft tribology methods with classic rheological methods.

References

[1] – Peng CL, Jost-Brinkmann PG, Miethke RR, Lin CT. Ultrasonographic measurement of tongue movement during swallowing. Journal of ultrasound in medicine. 2000 Jan;19(1):15-20.