Viscosity, put simply, resistance to flow, is a critical material property for many manufactured liquids. Accurate viscosity measurements under relevant test conditions are a necessity for anybody involved in the formulation, transport, storage and handling of suspensions, emulsions, solutions and melts.

Our lab can perform viscosity measurements across a range of temperatures and shear conditions relevant to your needs, delivering viscosity values in units of centiPoise (cP or “cps”) or milliPascal seconds (mPa.s).

On completion of testing you will receive a full report, including graphics, data tables and explanations. Whether you have a limited sample run, insufficient time to perform testing, or simply lack of equipment/expertise, we can help.

We have a wealth of experience testing a variety of complex materials. Every report includes ongoing Q&A support for interpretation or application of the results as part of our service offering.

Viscosity Testing of non-Newtonian Liquids

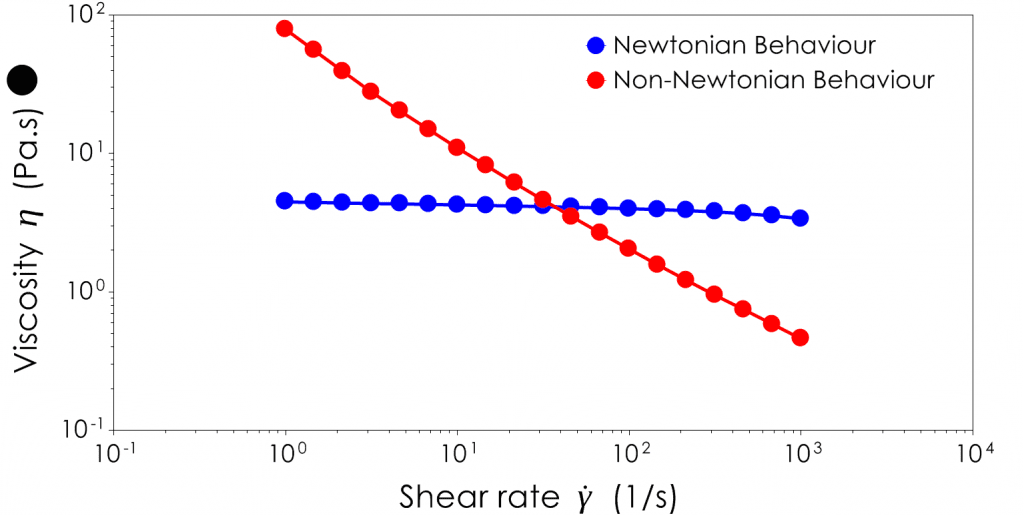

Most samples we receive include soft multi-phase materials, typically including suspensions, gels or emulsions, which tend to be non-Newtonian fluids. Non-Newtonian fluids change their viscosity dependent upon the degree of shear applied. For shear-dependent products, it is very useful to measure viscosity across a range of shear conditions. The resulting “flow curve” can help identify which viscosity values are relevant to your product or process.

Controlled Rate Viscosity Profiles

Viscosity/shear rate or shear stress/shear rate profiles, often termed rheograms, are a great way of understanding product behaviour under “forced-flow” conditions such as in pumping, mixing or filling processes. In this test, we apply a range of shear rates to the sample and measure viscosity throughout.

Controlled Stress Viscosity Profiles

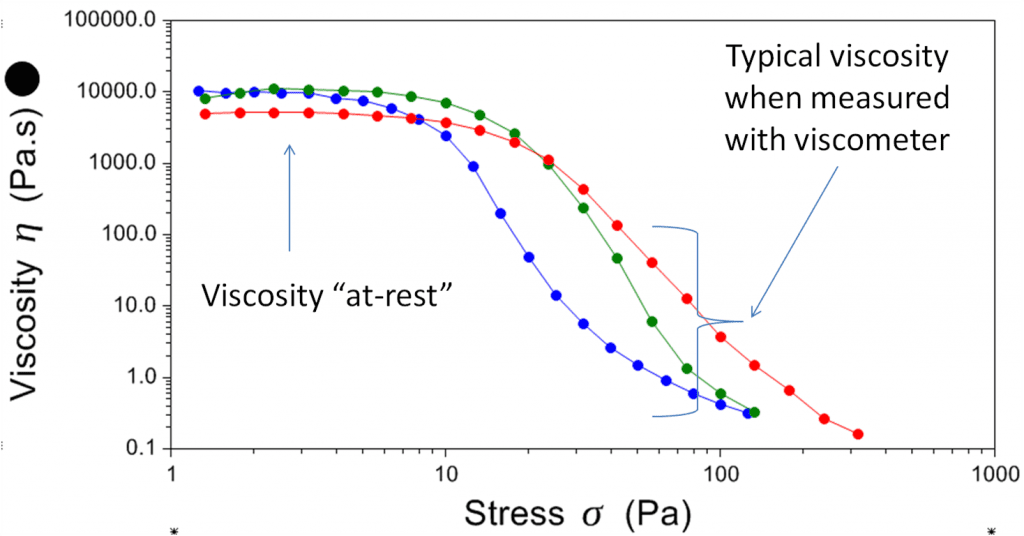

Viscosity/shear stress profiles are excellent for simulating altogether more gentle situations, where gravity, surface tension and capillary are the forces acting on the material. This is often the case in processes such as settling of suspensions, creaming of emulsions and draining and levelling of wet coatings.

Zero-shear viscosity measurements

Performing viscosity testing under very low shear conditions also enables the measurement of zero-shear viscosity. Zero-shear viscosity is a plateau value obtained at very low shear. Far below the range typically attainable with a viscometer. A high value of zero-shear viscosity can help to immobilise suspended solids or emulsified liquid droplets, contributing significantly to physical stability.

Viscosity measurements across a range of temperatures

The majority of liquids show a decrease in viscosity with increasing temperature. The degree of temperature dependence can be significant thus it is critical to measure viscosity under as close as possible conditions encountered in use, processing or storage. Our viscosity testing is performed under rigorous temperature controlled regimes. Our high sophisticated testing equipment enables us to study viscosity as a function of static or dynamic temperature conditions.

Brookfield Viscosity Testing

The term used to describe a viscosity value obtained with a Brookfield-type viscometer, rotational viscometer or similar-acting benchtop viscometers. These machines employ, typically, a rotating spindle that dips into a beaker of the liquid to be tested. Brookfield viscosity can be fearsomely confusing due to a multitude of instrument types and accessories, many combinations of which can deliver widely varying viscosity measurements. Our laboratory a full complement of Brookfield viscometer instruments and accessories and can identify and perform the most appropriate tests for your needs.

Calibration and Traceability

We can supply instrument calibration verification to certified, traceable viscosity standards.