We can provide a fast-turnaround soft tribology test service for your samples.

Our soft tribology test can provide comparisons of lubricity / “slipperiness” in a soft contact situation, similar to skin on skin contact processes such as spreading a topical product onto your skin, or sensing the texture properties of a soft material in the mouth. On completion of testing we will provide you with a full written report complete with graphical and numerical results and a detailed explanation.

Our soft tribology test can provide comparisons of lubricity / “slipperiness” in a soft contact situation, similar to skin on skin contact processes such as spreading a topical product onto your skin, or sensing the texture properties of a soft material in the mouth. On completion of testing we will provide you with a full written report complete with graphical and numerical results and a detailed explanation.

We have extensive experience in using tribology for evaluation of pharmaceutical, food and cosmetic products for a variety of applications such as sensory predictions, patent applications, re-formulation and market bench-marking. Any additional support you require to make use of the final report is included in the initial cost of testing.

Get a quick quote

Soft Tribology and Biotribology

Tribology is the study of the friction, lubrication and wear of interacting surfaces. Biotribology, or soft tribology, is  the specific study of compliant, biological surfaces such as the eyelid and cornea, tongue and palate, lips, mucous membranes or interacting skin surfaces. The film forming and lubricating ability of layers of liquids and viscoelastic materials applied to these surfaces provides a fascinating and powerful data set for formulators working on products such as:

the specific study of compliant, biological surfaces such as the eyelid and cornea, tongue and palate, lips, mucous membranes or interacting skin surfaces. The film forming and lubricating ability of layers of liquids and viscoelastic materials applied to these surfaces provides a fascinating and powerful data set for formulators working on products such as:

- Eye drops for dry eye conditions

- Generic pharmaceutical ointments, creams and lotions

- Fat-reduced foods

- Colour cosmetics, such as lipsticks, eye-shadow and eye-liner

- Moisturisers, lip balms and sun-care products

- Personal and intimate lubricants

Unlike rheology testing, where the sample under test is held in a defined gap between surfaces moving relative to each other, tribology testing entails bringing those surfaces into contact under a defined pressure and sliding one against the other, measuring the frictional drag over a range of sliding speeds. The surfaces and/or any applied lubricating liquid form the test sample..

Understanding the Stribeck Curve

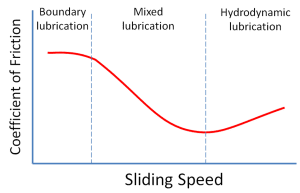

Tribology test results are often displayed in the form of a Stribeck curve such as that shown below:

The Stribeck curve anatomy is typically composed of three regions. At low speeds the surfaces are in close contact with asperities (surface roughness features) interlocking. Under these conditions lubrication is low, so friction is high. As sliding speed is increased the lubricant entrained between the upper and lower surfaces creates hydrodynamic lift, resulting in increasing separation of the surfaces and subsequent decreasing frictional drag. Lubrication at this stage is known as mixed boundary-hydrodynamic lubrication. Eventually, as sliding speed is increased, a complete separation of the surfaces ensues. Friction reaches a minima at this stage and the final part of the Stribeck curve anatomy is reached: hydrodynamic lubrication. From the key features of the Stribeck curve we can derive metrics that clearly differentiate between materials and differing lubricating qualities.

While direct interpretation of in-vitro measurements to sensory properties is difficult, and frought with complexity, it is possible to still gather some useful information to guide formulation design choices. By using the Stribeck curve as a ‘tribological fingerprint’ of a sample, a multi-variate approach coupled with rheology (such as that seen in our benchmark similarity scoring method) could help inform a formulator of what combination of physical properties could be utilised to target for a set of sensory properties.

We have a variety of standard and custom built attachments and test methods that enable accurate, repeatable tribology testing for a wealth of material types.