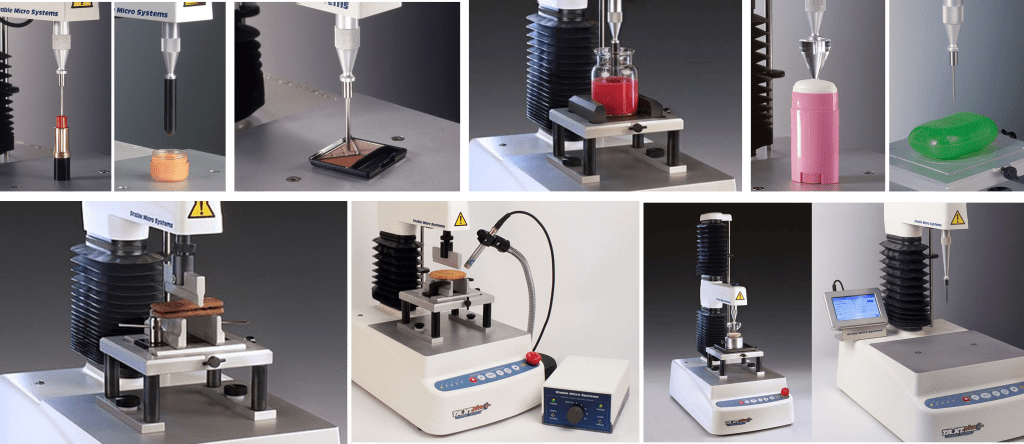

We provide texture analysis testing services and support for foods, cosmetics and many other materials. Our rapid turnaround service will deliver results and friendly, knowledgeable support to help you select and screen your raw materials and develop your products and processes.

For a quotation for sample testing or to discuss some practical training and support please get in touch.

What is texture analysis?

Texture analysis comprises a range of techniques that follow the simple principle of measuring force as a function of time or distance as a probe, fitted to a texture analyser, deforms a sample in either compression or tension. The probe is moved at a defined speed in either an up or, more commonly, down direction and the resisting force is measured throughout the test.

The variety of attachments and probes enables texture analysers to mimic a variety of real world interactions:

- Squashing/Crushing/Compressing/Squeezing

- Cutting/Biting/Slicing

- Poking

- Piercing/Penetration

- Pulling/Pulling off

- Dragging

- Extrusion/Back Extrusion

- Snapping/Tensile Testing

- Folding/Bending

An output graph will typically plot resisting force (N) as a function of either time or distance travelled by the probe.

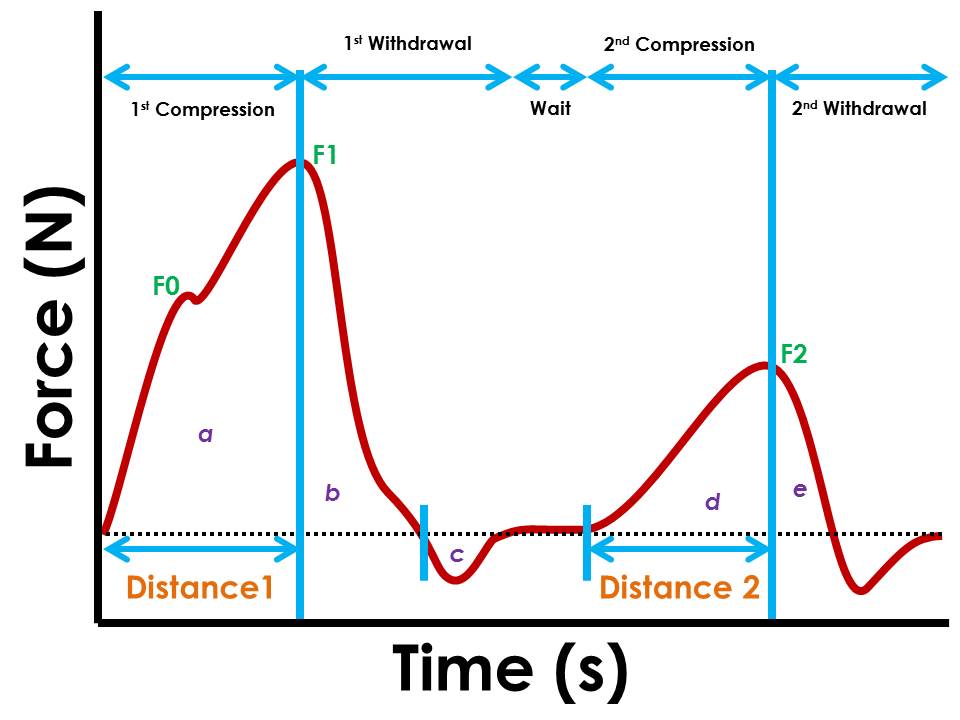

Texture Profile Analysis (TPA)

Within multiple industries, texture profile analysis seeks to quantify various physical properties such as hardness, adhesiveness, fracturability, cohesiveness, springiness, gumminess, chewiness and resilience by driving a probe into a sample at a specific rate, and repeating the compression.

Below is a schematic from a TPA test, indicating how one might use readings from the graph in calculations of a specific physical property or behaviour.

A TPA test generally follows a set format:

- 1st Compression

- The probe descends onto the sample, once contact is detected measurement begins and the probe descends at a defined speed, for a set distance or a set time.

- 1st Withdrawal

- Once the target distance/time is reached, the probe ascends away from the sample at a typically faster speed for a set distance or a set time.

- Wait

- The sample is allowed to recover before the process is repeated.

-

Fracturability (N) = F0

- The first significant peak in first compression.

-

Hardness (N) = F1

- The highest peak force measured during first compression.

-

Adhesiveness (N.s) = c

- The area under the curve for the first negative peak.

-

Cohesiveness = (d+e)/(a+b)

- The area underneath the second compression curve divided by the area underneath the first compression curve.

-

Springiness (%) = (Distance 2)/(Distance 1)*100 or (Time 2/Time 1)*100

- A ratio or percentage of a product’s recovery to its original height.

-

Gumminess (N) = F1 * ((d+e)/(a+b))

- Hardness x Cohesiveness.

-

Chewiness (N) = (F1*Distance 2)/(Distance 1*(d+e)/(a+b))

- Hardness x Cohesiveness x Springiness.

-

Resilience = b/a

- The area under curve after peak force is reached divided by area under curve before peak force is reached.

Texture profile analysis is one of our most popular tests to perform on a texture analyser. It is important however, to use an appropriate method for the physical property of interest.

If you are unsure which method is appropriate to objectively quantify your behaviour or property of interest, feel welcome to contact us to discuss your requirements.