Rheo-Impedance Spectroscopy (Rheo-IS) is a groundbreaking technique that unlocks a new dimension in the characterisation of complex fluids by simultaneously measuring their mechanical and electrical properties. Rheo-IS combines powerful rheological profiling, which studies the viscosity and viscoelasticity of materials, with impedance spectroscopy, which probes microstructure through how materials resist and “react against” electrical signals across a range of frequencies.

Rheo-IS delivers a unique new angle on material behaviour, making it a potent tool for researchers and product developers working with a wide variety of complex fluids, including:

- Emulsions and suspensions

- Surfactant and polymer solutions

- Slurries and sol-gel systems

What is Impedance Spectroscopy?

Electrochemical Impedance Spectroscopy (EIS), to give it its full name, is a technique that measures how a material responds to an alternating electrical current. The technique is widely used in batteries, fuel cells, coatings, and biomaterials to probe microstructure through its electrochemical impedance fingerprint.

Impedance is the opposition to an alternating electrical current. It is made up of two components:

- Resistance: The opposition to any electrical flow.

- Reactance: The additional opposition to electrical flow experienced by alternating current when capacitance or inductance is present.

How is this relevant to liquids and semisolids?

Higher continuous phase viscosity, the presence of restricted pathways in high concentration emulsions or suspensions, or the presence of polymer chain entanglements, results in reduced ion mobility. This reduced mobility manifests as dissipation, in other words, electrical resistance.

Additionally, if the material stores charge through, for example, interfacial polarisation or electrical double-layer formation, this is a manifestation of capacitance. An alternating current passed through the material will “feel” this as reactance. Impedance spectroscopy can capture these properties.

Why Combine Rheology with Electrochemical Impedance Spectroscopy?

In real-world applications, materials experience mechanical forces and temperature changes enroute to their final destination.

For example:

- A battery slurry is mixed, pumped, and coated before it dries.

- A printed electronic ink is sheared during jetting or screen printing.

- A catalytic coating is sprayed or dip coated.

- A topical pharmaceutical is sheared and warmed as it is spread.

Traditional EIS methods measure materials at rest, missing the impact of real processing conditions. Rheo-IS solves this problem by simultaneously applying controlled shear and temperature profiles, to simulate real-world storage, processing or application conditions, while measuring probing microstructure through rheology and impedance spectroscopy.

This allows researchers to:

- See how shear and temperature influence impedance – Does a conductive network survive or break under flow or temperature changes?

- Optimise formulations – Is there an ideal filler or polymer content for electrical performance?

- Detect subtle structural changes – Does a coating reorganise at the microscopic level when sheared, following shearing or throughout curing?

How does Rheo-Impedance Spectroscopy work?

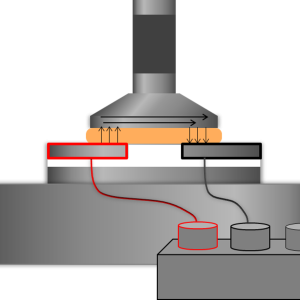

Rheo-IS uses a specially designed electrode system built into the rheometer plate, enabling simultaneous mechanical and electrical characterisation of a sample.

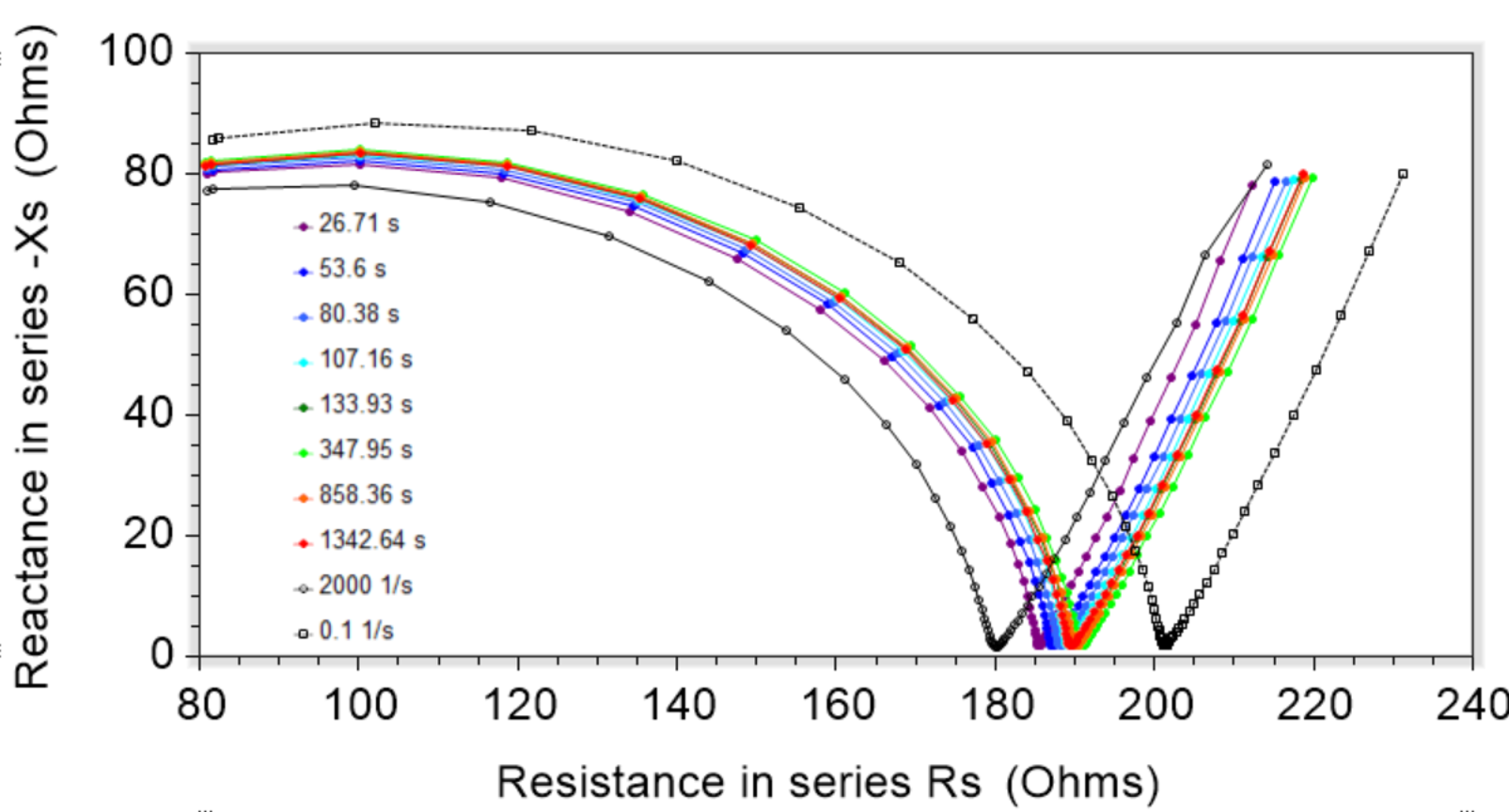

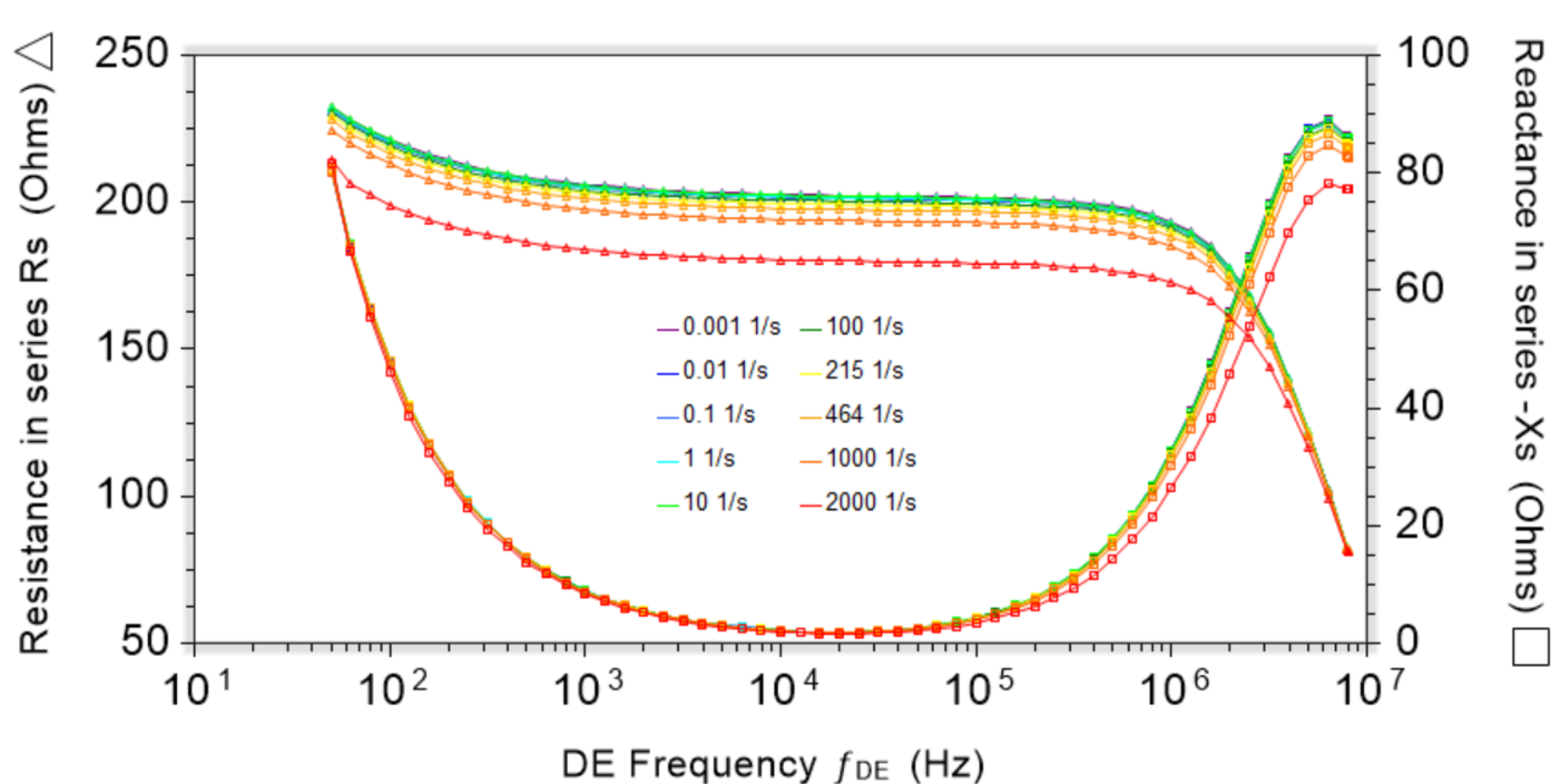

One plate rotates relative to the other to create steady shear (in one direction) or oscillatory shear (sinusoidal clockwise and counterclockwise), generating disruption and flow. By applying a small alternating electrical signal across the electrodes, Rheo-IS measures the material’s resistance and reactance. The frequency of the applied current is swept and the resulting impedance spectra is displayed in two ways:

The Nyquist Plot: Reactance is plotted vs Resistance

The Bode Plot: The overall impedance and phase angle (between applied voltage and resulting current) vs frequency

Rheologists will notice the parallels here: The Nyquist plot reflects the Cole-Cole plot of loss modulus vs storage modulus, and the Bode plot parallels complex modulus and phase angle graphed against frequency.

The beauty of combining rheology measurements with impedance spectroscopy is two-fold:

- Firstly, the ability to gather impedance spectra before, throughout and after the application of clearly-defined shear and temperature conditions, is a powerful capability.

- Secondly, the ability to simultaneously gather viscosity or viscoelasticity data throughout the test enables the correlation of rheological and microstructural insights.

Rheo-Impedance Spectroscopy is a breakthrough in materials characterisation. Whether for battery electrodes, printed electronics, biomedical gels, or functional coatings, it provides a new level of insight into how materials behave under real-world conditions.

We would like to thank Kevin Whitcomb at Waters-TA Instruments for his generous permission to use the graphics featured in this article.