Powder wettability measurements are vital for predicting or understanding the interaction between a powder and liquid in several key processes. For example, dispersibility of powders into a liquid, improving bioavailability of drugs, minimising powder-liquid mixing issues, ensuring the ground is appropriate for farming, building, etc.

Powder wettability measurements are vital for predicting or understanding the interaction between a powder and liquid in several key processes. For example, dispersibility of powders into a liquid, improving bioavailability of drugs, minimising powder-liquid mixing issues, ensuring the ground is appropriate for farming, building, etc.

The Centre for Industrial Rheology offers a number of physical characterisation services for powders and liquids including, measurement of powder wettability, measurement of flow and surface properties for the wetting liquid and wetted powder respectively

If you have a powder and liquid combination that you would like to benchmark against a new formulation or competitor or would like to identify key parameters to optimise your process, then please feel welcome to contact us.

Contact us to arrange a discussion of how we can help

Powder wetting, capillary behaviour and dispersion

When introducing insoluble powders to liquids for the purpose of dispersion, the process can be split into three distinct situations: in the first instance when a liquid meets a powder, the interaction is driven by the interfacial tension between the liquid droplet and surface of individual powder particles.

As the spaces between particles wet, capillary action drives the liquid in-between the voids of individual particles, either wicking the liquid further into the powder mass or preventing further ingress. If the attractive forces between powder particles are sufficiently weak, then as more liquid is added the powder may disperse within the liquid.

Problems with powder dispersibility

Air entrapment and foaming are common powder mixing problems as the powder particles themselves can help stabilise the interface between liquid and air. Lumps or “fisheyes” can also form when a large amount of powder is added to a liquid too quickly, particularly if the powder is already cohesive. As the powder meets the liquid, a protective shell can form around a large mass of unwetted powder preventing breakup, continued wetting or mixing to homogeneity.

Particle size, particle shape and particle density are among some of the key properties determining powder handling properties, with powder porosity, paging, homogeneity and contact angle being other metrics affecting dispersibility.

We offer several material characterisation services for powders and liquids including powder flowability, rheology measurements and wettability.

The Washburn Capillary Rise Method – Powder Wettability Testing

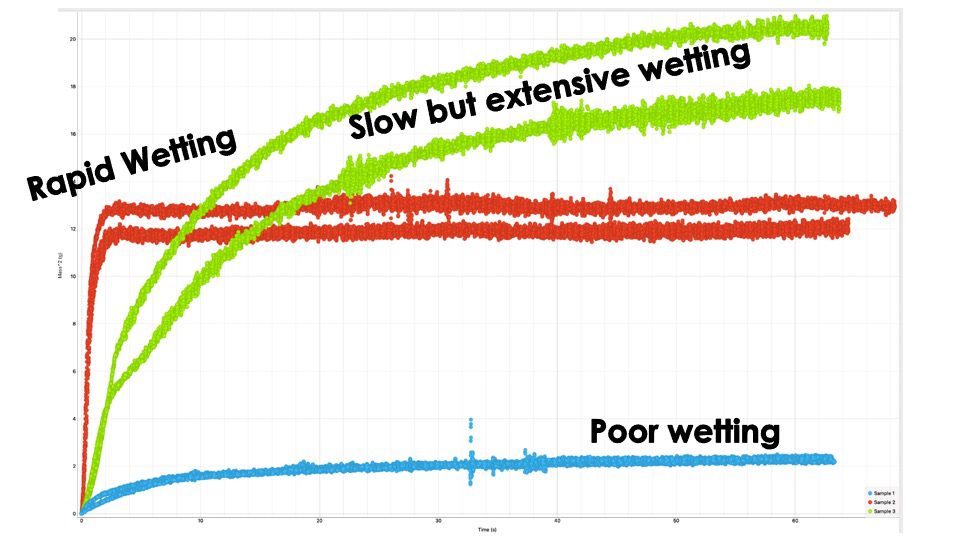

The Washburn capillary rise method involves interfacing a conditioned column of powder to a liquid of interest and tracking the rate of liquid uptake into the column through capillary forces.

Dry Powder Characterisation

Our powder rheometer can run a number of tests to look at angle of internal friction, flow function, compressibility, permeability and frictional properties of powders.

We will often run a conditioning step on the powders to improve repeatability of the test and minimise sample preparation errors. This typically includes agitation of the powder using a twisted blade rotating through a column of powder. Once the powder has been mixed a vented piston compresses the powder to a set volume and compaction. For more information on the variety of tests we can perform, feel free to explore our powder testing services page.

Powder and liquid characterisation from one lab

Our lab specialises in measuring physical properties of soft materials, and helping customers describe and quantify complex physical behaviours. If you have a range of samples that you would like to send to us for characterisation or would like to arrange a virtual tour of the lab, then please feel welcome to call or email us to arrange a meeting.