Aquafaba is becoming an increasingly common replacement for egg white in a number of goods as customers and manufacturers look to reduce their impact on the environment. Collecting viscosity data for the mother liquid and by comparing the viscoelastic properties of the foams, a rheological profile of egg white and aquafaba in both liquid and foam state was generated.

Foams and foaming behaviour

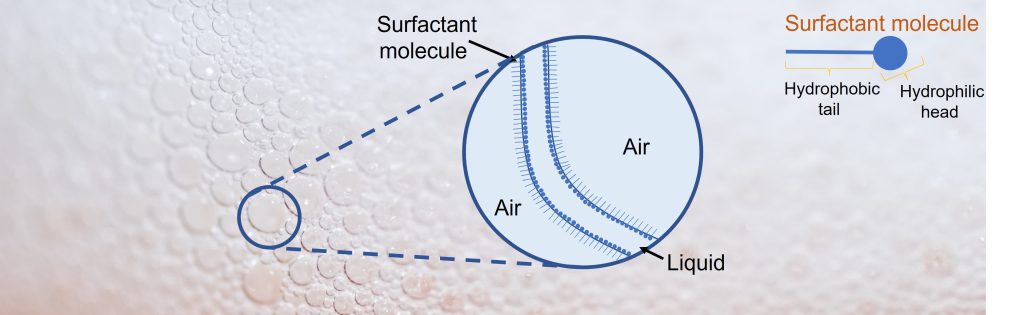

Foams are defined as ‘a dispersion in which a large proportion of gas by volume in the form of gas bubbles, is dispersed in a liquid, solid or gel’. There are two main types of foams:

- Dilute foams, where the bubbles are nearly spherical and are separated by a thick film of viscous liquid and;

- Concentrated foams, where the foam is mainly comprised of gas phase and polyhedral cells are separated by thin liquid films.

Contact us to arrange a lab tour and discuss rheological techniques with our experts

The hydrophilic head-group resides in the liquid phase and the hydrophobic tail-group reaches into the air pocket, surrounding the air bubble and stabilising it within the coating liquid. This prevents the air bubbles from agglomerating and rising to the surface to escape.

The stability of a foam depends upon two main factors:

- The tendency of the liquid films making the foam to drain and become thinner;

- The tendency of the foam to rupture as a result of random disturbances.

Evaporation and gas diffusion through the films may also affect the foam’s stability.

Probing foam structure and stability

Using rheology, it is possible to monitor numerous aspects that influence the stability and structure of the foam. For example, a high bulk viscosity (easily measured by collecting a viscosity profile) will retard the rate of foam collapse and coalescence of bubbles. In addition, the elastic (G’) and viscous (G’’) moduli of a foam (measured using oscillatory techniques) will provide valuable information in relation to the rigidity, and therefore persistence, of the structure.

The demand for environmentally friendly, plant-based products that have similar rheological profiles (e.g. thickeners, gelling agents, emulsifiers, foaming agents) to the animal-derived equivalent is increasing. In recent years, aquafaba has commanded interest as an egg-replacement because it exhibits several properties similar to those of egg white, including high viscosity and the ability to form gels and foams. We compared the properties of aquafaba and egg white foams using rheological techniques.

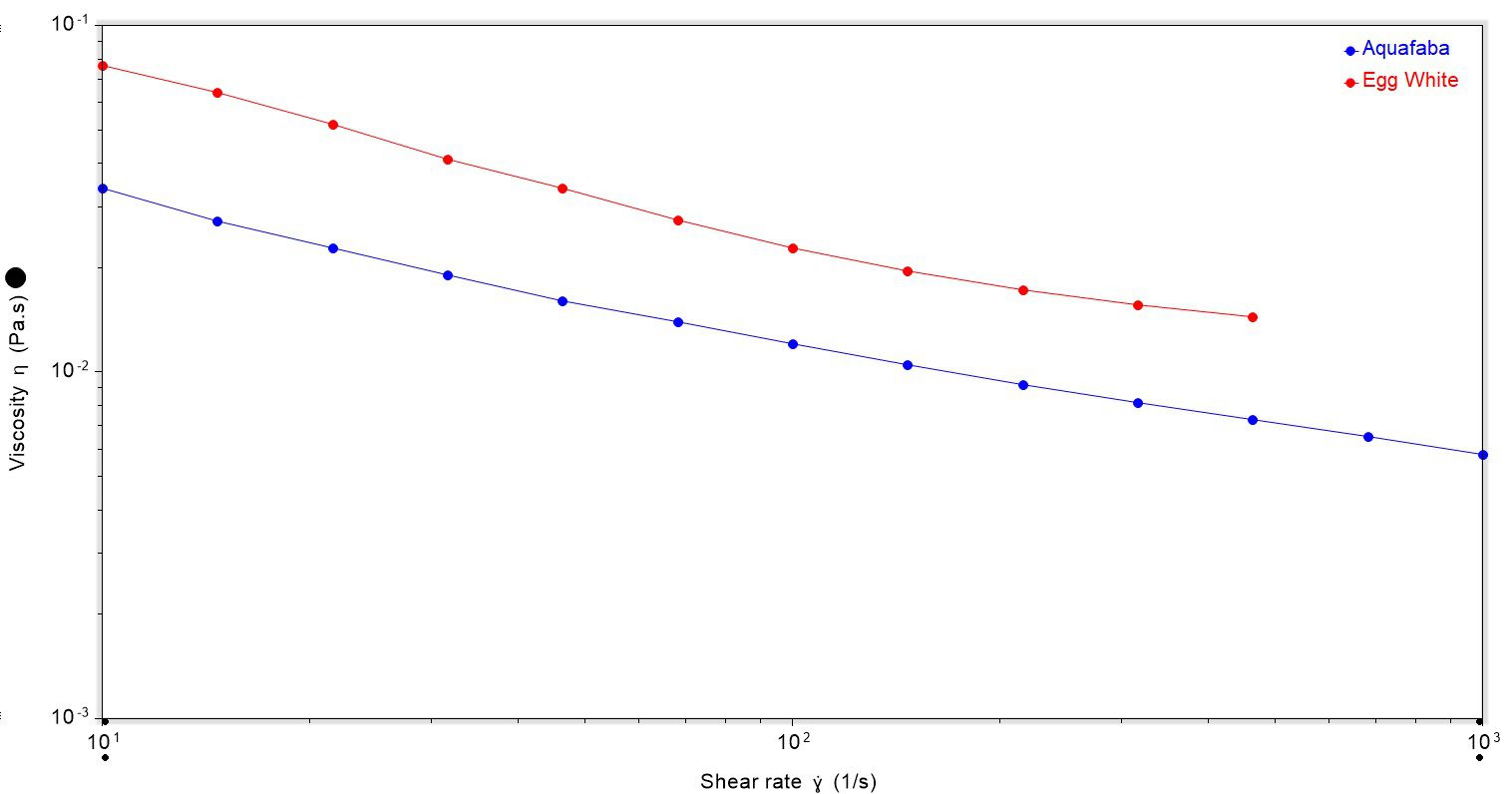

Comparing viscosity and identifying normal stress

Controlled-rate viscosity profile (CRVP) data showed that both the aquafaba and egg white mother liquors were non-Newtonian, shear-thinning materials, Figure 1. Egg white was more viscous than aquafaba across the shear rates tested. This infers that foam made from egg white may be more stable than foam made from aquafaba as the more viscous material will hold the bubbles apart more effectively, preventing coalescence.

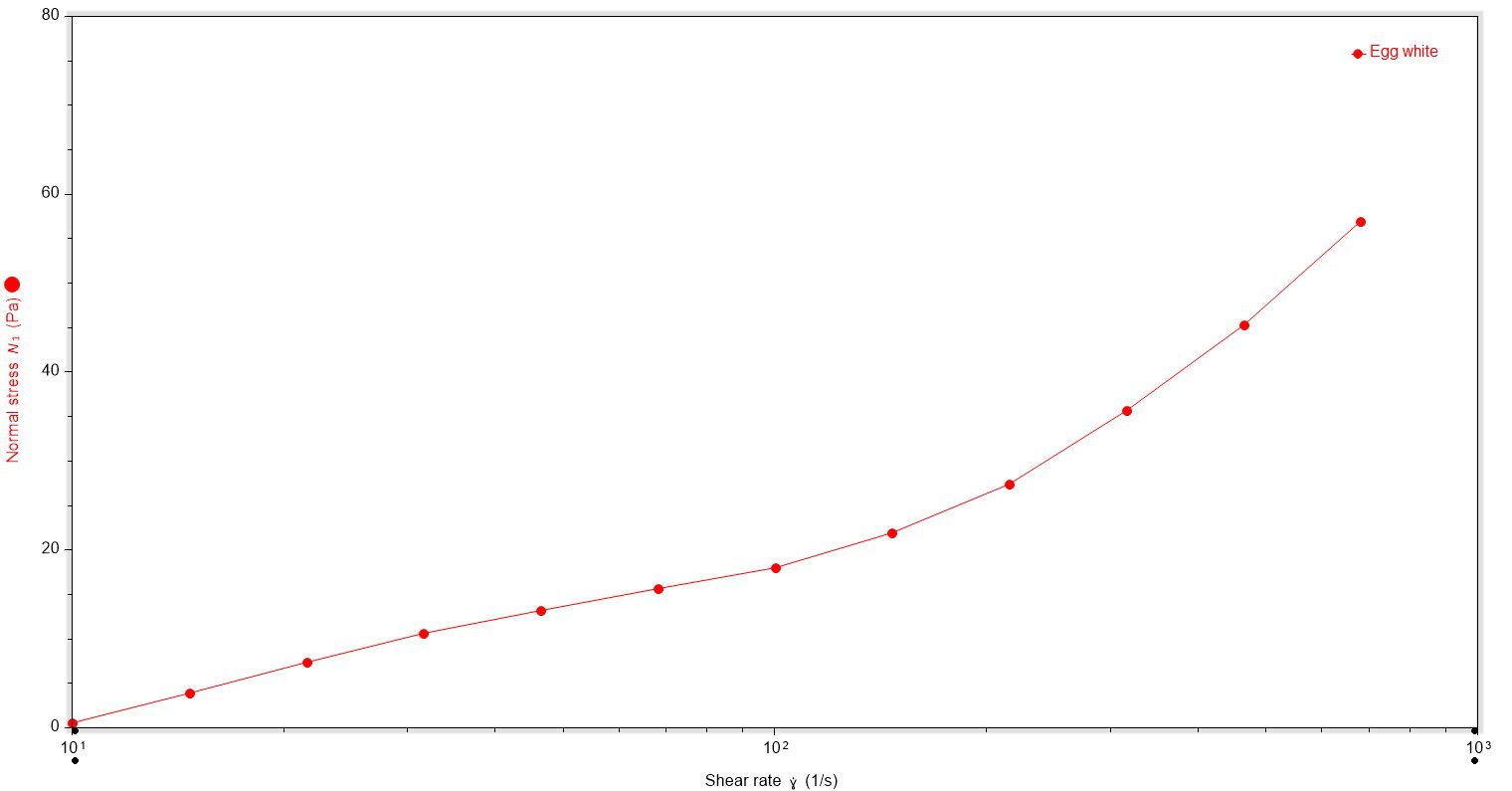

The CRVP data also provided insight into the properties of the egg white by revealing an increase in normal stress as shear rate increased, Figure 2. This phenomenon usually occurs within polymers, where at low shear rates the polymeric chains are entangled but at higher shear rates the chains disentangle and stretch. The chain stretching causes a measurable force ‘normal’ (i.e. perpendicular) to the direction of shear. The same is true for egg white; as the shear rate is increased the protein chains within the egg white stretch and exert force normal to the shear direction. Normal stress generation can also lead to ‘rod climbing’ up a stirrer or shaft during processing.

Foam yield stress and irreversible deformation

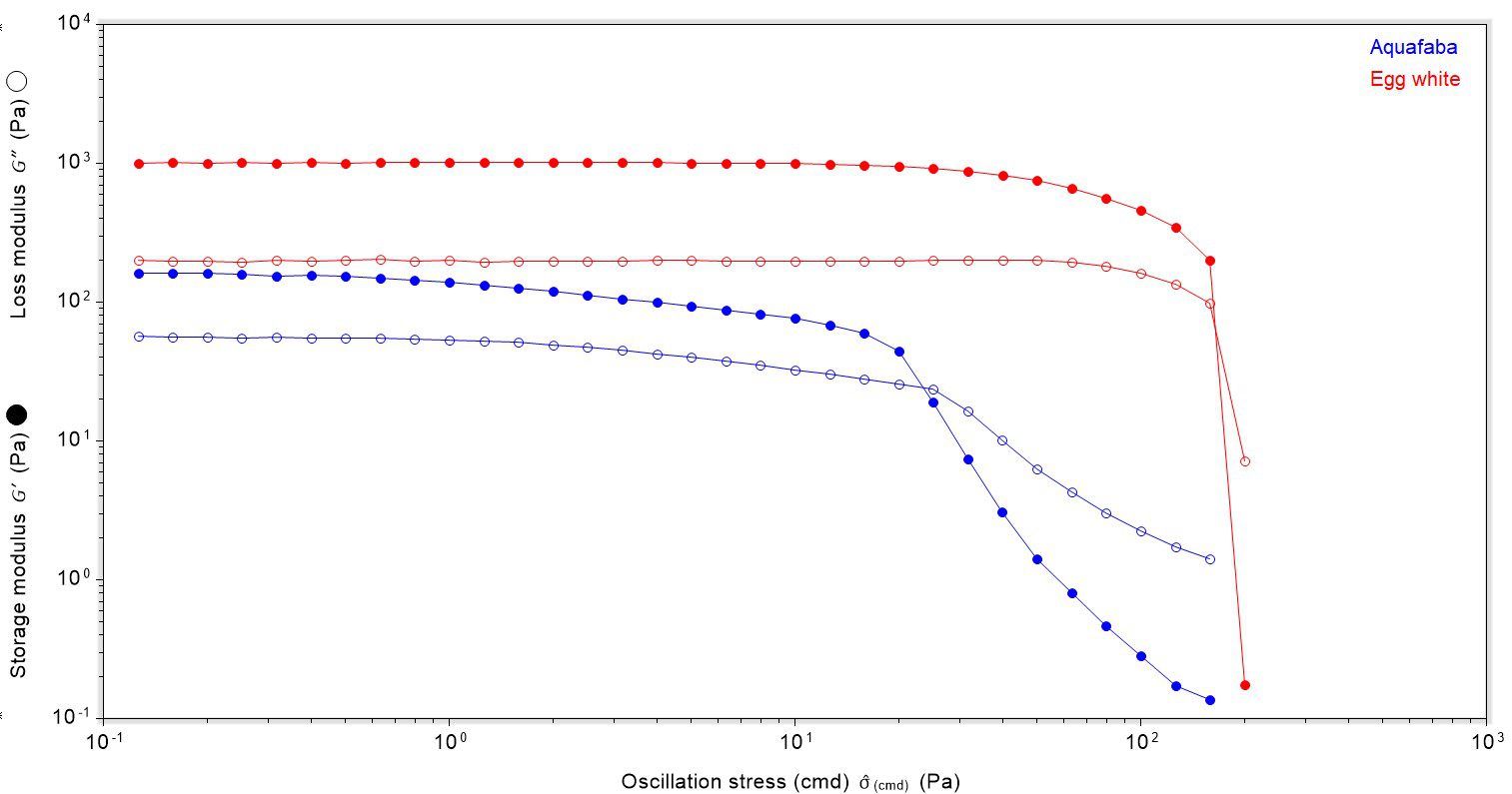

To prepare the foams, samples were whipped using a Kenwood food processor with balloon whisk attachment for 10 minutes at a high whisking rate. Oscillatory strain sweeps provided information about the rigidity of the foams, in particular the storage and loss moduli. In both cases, the storage modulus was higher than the loss modulus indicating solid-dominant behaviour, Figure 3. The difference between these moduli was much larger for egg white, indicating a greater degree of solid dominance.

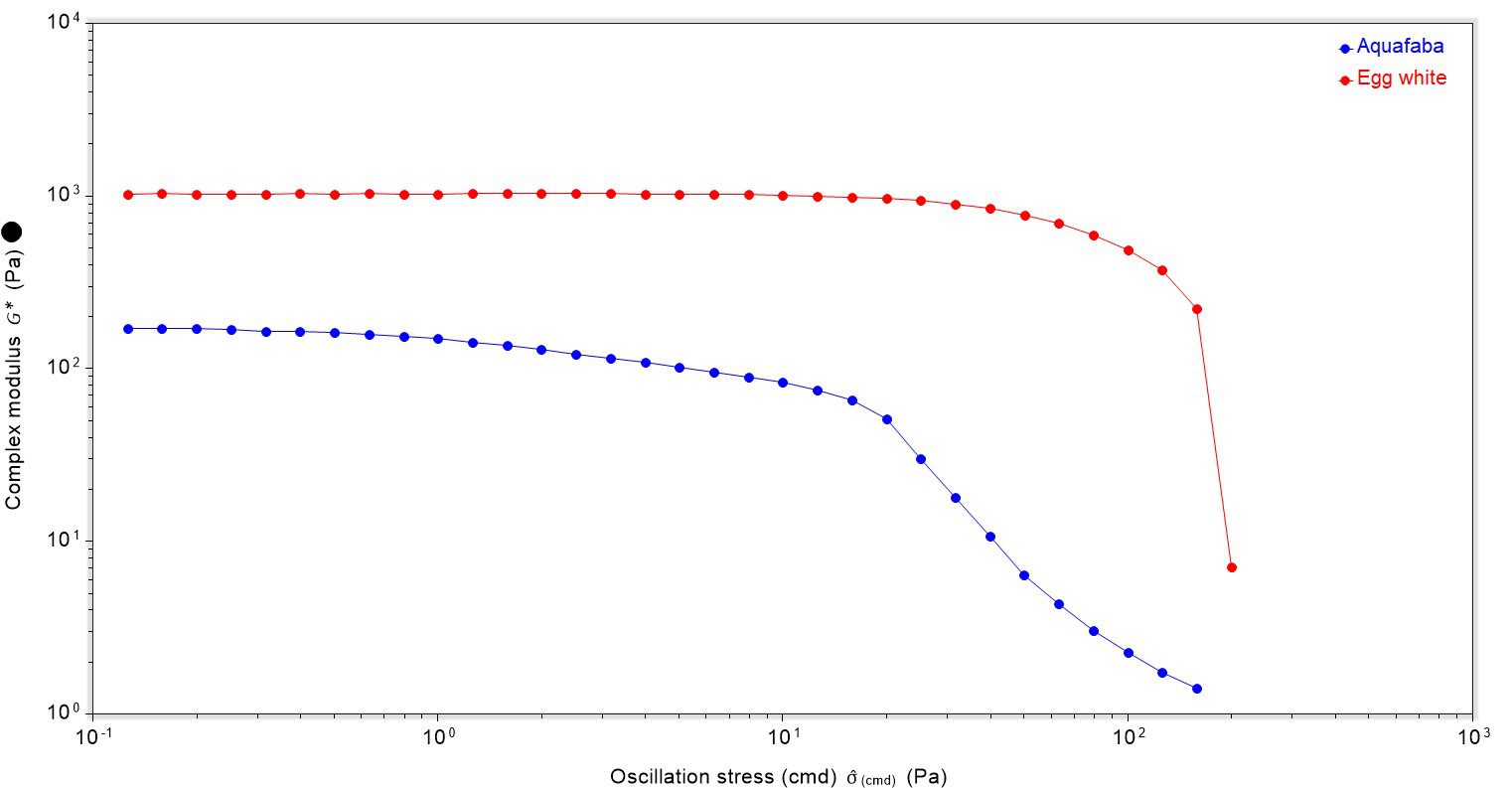

The point at which the deformation cannot be recovered and the structure undergoes significant irreversible deformation is known as the yield stress. Yield stress can either be determined using the cross-over point of the storage and loss moduli, or the point at which the complex modulus (a combination of the storage and loss moduli contributions) starts to decrease. The point at which the storage modulus starts to decline (i.e. the end of the linear viscoelastic region) shows when the stress applied to the material stops being relative to either the strain or shear rate and deformation is irreversible; any stress applied cannot be easily correlated with any micro-structural properties. The cross-over point shows where behaviour changes from solid-dominance to viscous-dominance and signals a significant yield event. These approaches will give two slightly different results, with the onset of complex modulus decline giving the lower value.

As indicated by the cross-over point of the viscous and elastic moduli, the complete loss of structure of egg white foam occurred at 123% strain or 64 Pa of stress. For aquafaba foam it occurred at 80% strain or 24 Pa of stress. This shows that to completely degrade the aquafaba foam requires less stress (and strain) than the egg white foam.

The complex modulus data clearly show the difference in rigidity between the egg white and aquafaba foams, with egg white foam being comparatively more rigid, Figure 4. Using the onset-point method, the beginning of significant irreversible deformation for egg white foam occurred at 78 Pa stress, and aquafaba at 12 Pa stress.

This shows that for egg white, the start of significant irreversible deformation is at lower stress than for aquafaba (78 Pa vs 12 Pa, respectively) but the change from solid to liquid-dominance requires a great deal more stress (123 Pa vs 24 Pa, respectively) i.e. for aquafaba the onset of significant irreversible deformation and change from solid to liquid dominance of the structure is in a much smaller window. In terms of stress required to induce the initial deformation, the observation that egg white required more force shows that the structure is more rigid and hardy. The window between deformation starting and change of solid or liquid dominance in the structure is larger for egg white than aquafaba.

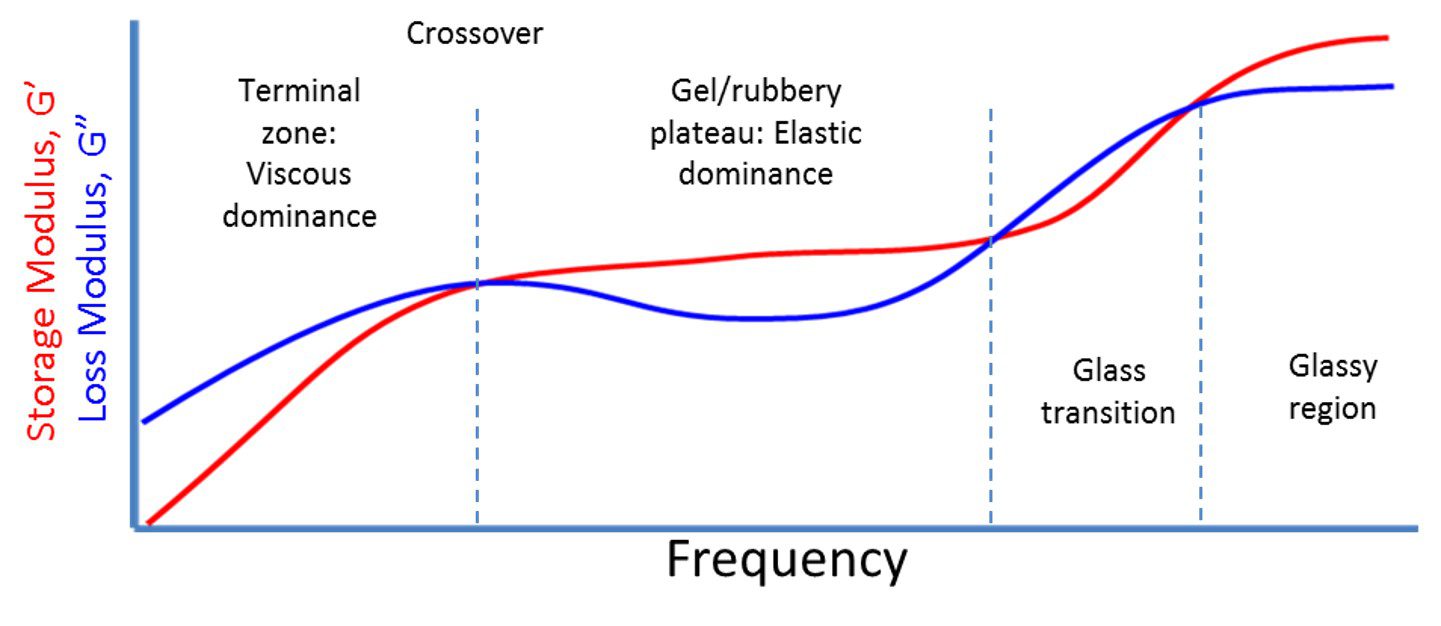

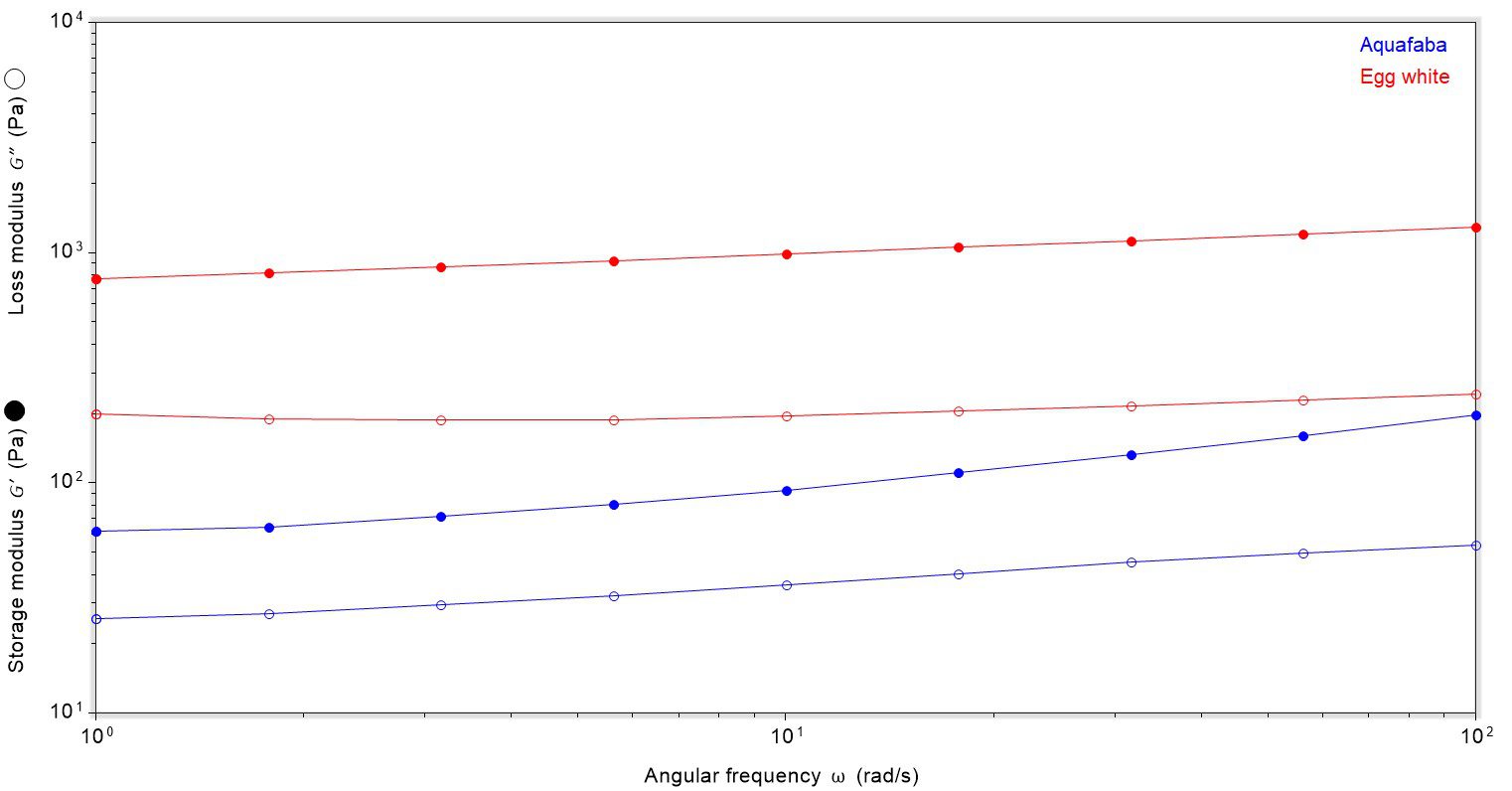

The final test was an oscillatory frequency sweep to probe behaviour of both materials within the linear viscoelastic (LVE) region, as determined by the oscillatory strain sweep (OSS). This valuable test can provide further insight into behaviours such as glass transitions, elastic dominance and viscous dominance, Figure 5.

OFS data for egg white and aquafaba clearly showed that both materials were within the elastic dominant regime, Figure 6.

In summary we have probed the behaviour of egg white and aquafaba liquids and foams from a rheological perspective. Both liquids were non-Newtonian, shear-thinning. Once in foam form, egg white had a much stronger structure that could withstand more stress than aquafaba, as shown by the oscillatory strain stress data. This data is likely of interest to process engineers, product developers and food technologists who may be looking to replace egg in products with non-animal derived alternatives.

For further information about these tests, or the range of tests that we offer, please contact us.