The use of research rheology offers unique capability for interrogation of cooling behaviours of plant-based protein products. When compared with the commonly-used texture analysis instrumentation, rheology can provide significant advantages, especially when measuring food texture profiles at elevated temperatures as the temperature control is much more precise.

We have shown that determining complex modulus and yield stress at 25 °C and 50 °C can be used to benchmark plant-based protein products both against each other and the equivalent animal-derived product, providing valuable information about the texture of products when hot and cold. In addition, we can quantify if products are strong, weak, wobbly or rigid in comparison to each other; a valuable tool in the quest for product improvement or development. This work is a good starting-point for future studies and is likely of interest to food scientists, research and development scientists and process scientists, particularly those working within the vegan, plant-based protein/meat or cultured/cultivated meat markets.

If you would like to discuss how to characterise key rheological properties of your own products, please feel welcome to contact us.

Plant-Based Protein: Quantifying Succulence

Within the plant-based protein market, a key aim is development of a product that is as close to the animal-derived original as possible. There are several challenges in reaching this goal, but one that is especially difficult to address is the replication of mouthfeel and succulence of a meat product, particularly during cooking and cooling processes. These parameters are commonly explored using a texture analyser but collecting data on samples that are warm is notoriously challenging. However, by using rheology these parameters can be analysed at a range of temperatures, providing a valuable alternative (or complementary) approach. The texture profiles of eight plant-based protein products marketed as either burgers or sausages were compared with those of a beef burger and a pork sausage using advanced rheological techniques. In this article, the plant-based meat products are referred to as ‘alt-meat’ products.

Within the plant-based protein market, a key aim is development of a product that is as close to the animal-derived original as possible. There are several challenges in reaching this goal, but one that is especially difficult to address is the replication of mouthfeel and succulence of a meat product, particularly during cooking and cooling processes. These parameters are commonly explored using a texture analyser but collecting data on samples that are warm is notoriously challenging. However, by using rheology these parameters can be analysed at a range of temperatures, providing a valuable alternative (or complementary) approach. The texture profiles of eight plant-based protein products marketed as either burgers or sausages were compared with those of a beef burger and a pork sausage using advanced rheological techniques. In this article, the plant-based meat products are referred to as ‘alt-meat’ products.

Complex modulus and yield stress: Tools for texture profiling

Complex modulus

Determination of the complex modulus can provide insight into the resistance to deformation of a soft-solid material, regardless of whether that deformation is recoverable (elastic) or non-recoverable (viscous). This is important, as it means that the complex modulus can be a key value when assessing the flex and toughness of a material – essential qualities for consumer perception. A smaller complex modulus infers that a material is wobbly, and a larger complex modulus infers that a material is rigid.

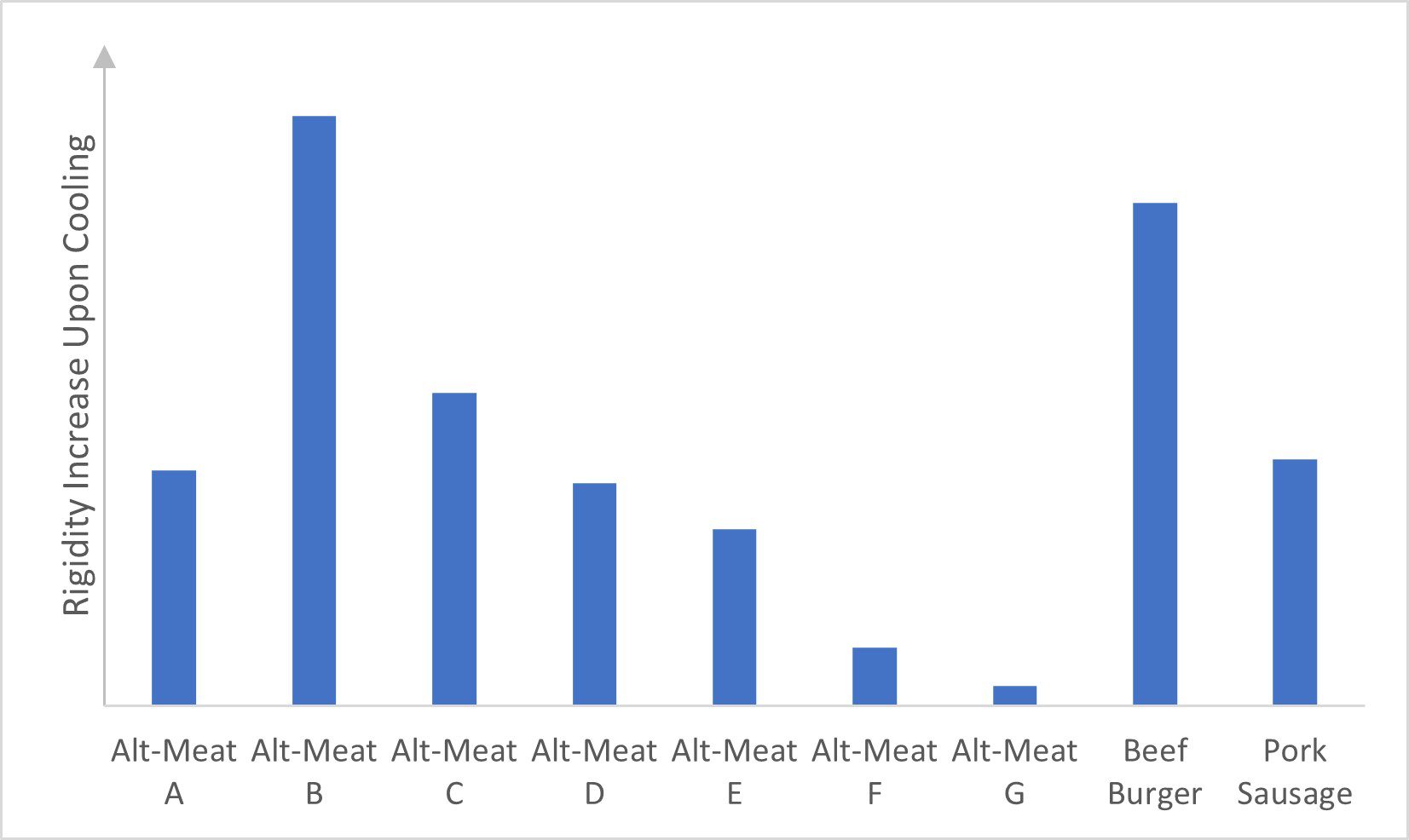

In all cases the complex modulus increased upon cooling, indicating a tendency towards a more rigid structure, or hardening. Plotting the change in complex modulus allowed for facile comparison of data and rapid identification of trends, Figure 1. A large number means that there has been a big change in complex modulus. Looking at these data, it can clearly be seen that the beef burger becomes much more rigid upon cooling than a pork sausage. Interestingly, across the alt-meat products studied there were some items that significantly hardened upon cooling (alt-meat B) or some that showed very little change (alt-meat H). Several products showed a similar magnitude of change to that of the pork sausage, regardless of whether they were marketed as a plant-based burger or plant-based sausage.

Complex modulus vs yield stress

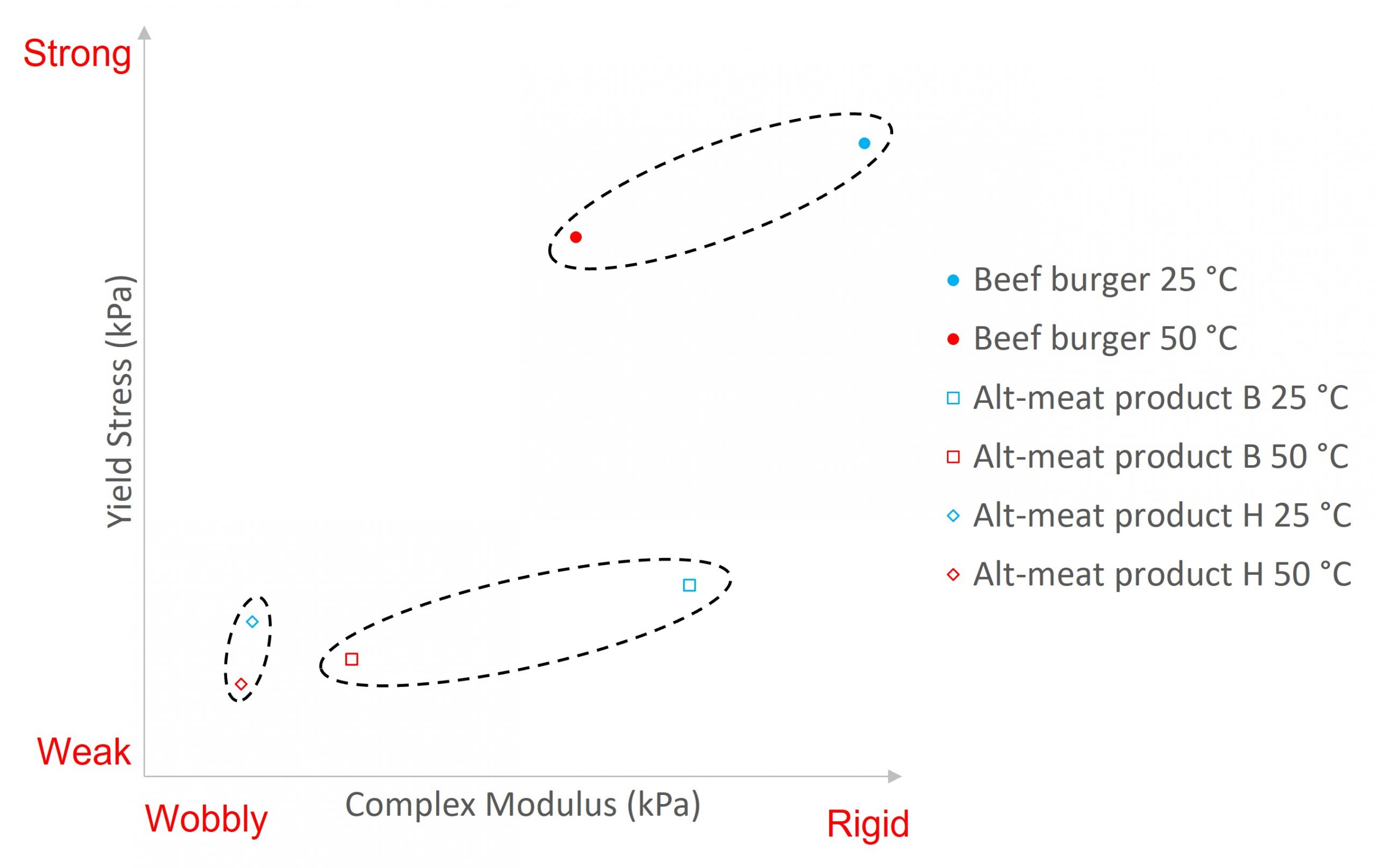

Plotting yield stress against complex modulus allows generation of a texture map, allowing facile comparison of data. Where complex modulus can provide insight into the resistance to deformation of a soft-solid material, the yield stress determines what stress that must be applied to disrupt internal structure and elicit a significant decrease in viscosity, or in this case complete destruction of the internal structure. A small yield stress infers that a material is weak, and a large yield stress infers that a material is strong.

Using the yield stress versus complex modulus data allowed characterisation of materials within four parameters: weak, wobbly, rigid and strong. Therefore, materials with low yield stress and low complex modulus were classified as weak and wobbly, e.g. soft beef gelatine, and materials with high yield stress and high complex modulus were classified as strong and rigid e.g. well-cooked steak. It should be noted that these terms are relative, and a material identified as weak and wobbly in this study may be significantly tougher or stronger than materials in another study.

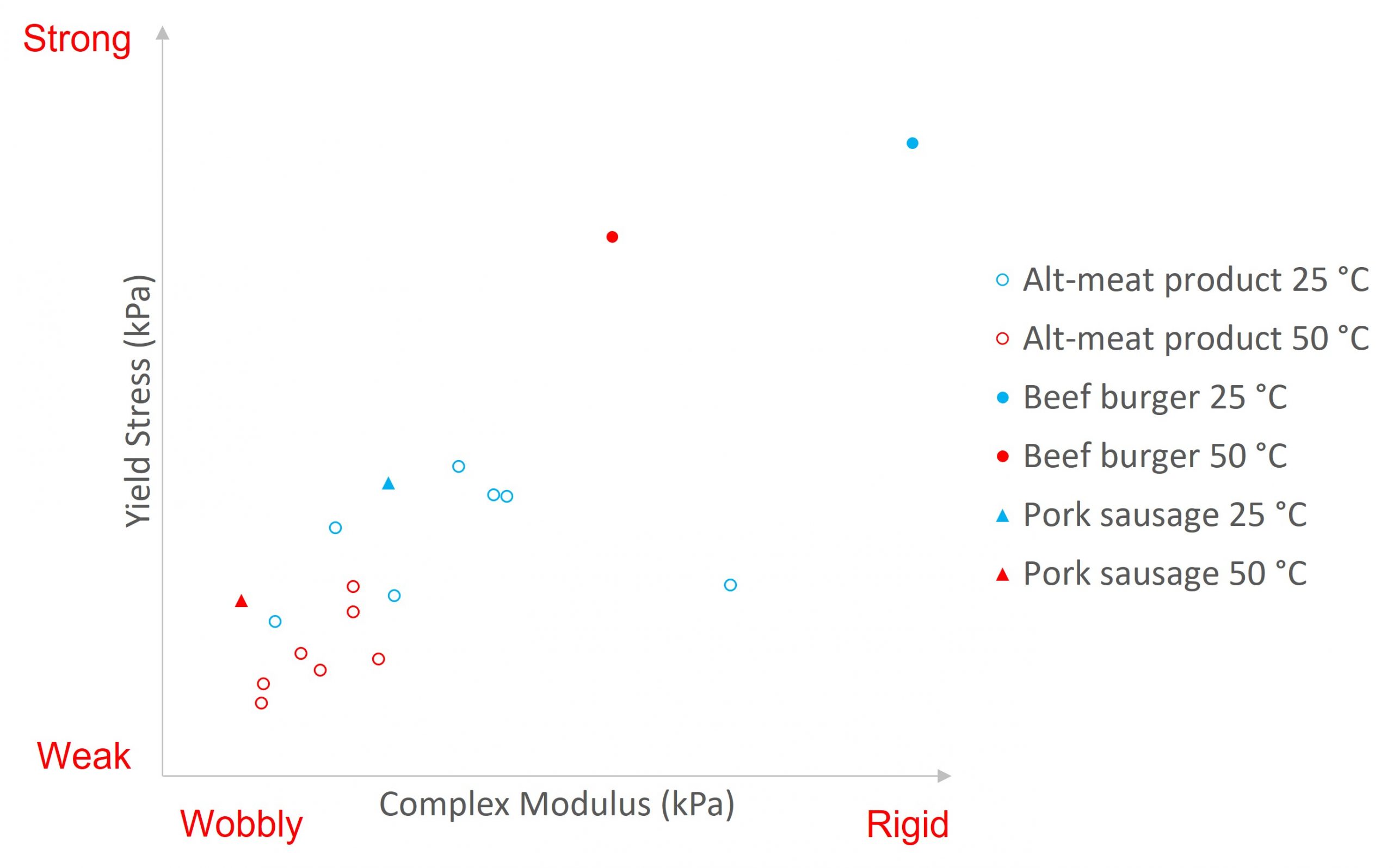

Once the data were plotted, it could quickly be seen that at 50 °C all the materials, with the exception of the beef burger, were clustered towards the bottom left of the plot indicating that they had a similar texture to each other that was tending towards weak and wobbly, Figure 2. At 50 °C the beef burger was more rigid and stronger than the other products in the study. Upon cooling, the complex modulus increased, indicating a tendency towards a more rigid structure or hardening, and the yield stress increased, indicating the presence of a stronger structure that required more force to disrupt. This meant that at lower temperatures all the products in the study became more rigid and stronger, tending towards the top right. Again, the beef burger was the strongest and most rigid in comparison with the other materials tested at 25 °C.

The key take-home message here is that in terms of texture, none of the alt-meat products showed a profile similar to beef and all were more similar to the pork sausage, both when warm and cold. This was the case if the product was advertised as either a sausage or a burger replacement. Interestingly, upon cooling the alt-meat products showed a large range of textural variation, which may be an avenue for exploration in terms of consumer perception of a product and if customers perceive certain products to be mushier or tougher than others during cooking or cooling processes.

Looking more closely at specific products

These data are clearly interesting, but further interrogation of individual products provides even more information and allows for investigation into behaviour by a particular product or brand, as well as further benchmarking, Figure 3. For example, as noted earlier the beef burger significantly changed in structure and became more rigid, as shown by an increase in the complex modulus, and more energy was required to break the burger matrix, shown by an increase in the yield stress. This is in-line with anecdotal observations during BBQs; as beef burgers cool, they become more rigid and have a stronger structure i.e. they toughen. The same behaviour was observed with alt-meat product B, where the product became more rigid upon cooling, although the yield stress remained low; alt-meat product B is arguably weaker and more wobbly than a beef burger both at higher and lower temperatures. Contrastingly, alt-meat product H showed very little change in the yield stress and complex modulus upon cooling, staying weak and wobbly, so arguably the cooled product and hot product have very similar rigidity and strength characteristics. However, alt-meat product H is considerably weaker and wobblier than the beef burger, which may not be a desirable characteristic. The combination of complex modulus with yield stress provides additional information and a further dimension for analysis of data.

Summary

This article shows that key parameters surrounding texture of alternative meat products can be measured using rheological techniques. The major advantage of this over texture analysis is that temperature can be easily varied, giving a fuller picture. As the alternative meat markets grow, either for plant-based or cultivated meats, these capabilities will provide valuable support for those working in development and manufacture of these cutting-edge products.

At the Centre for Industrial Rheology, we perform the tests in this case study and a whole host of others, working closely with our customers to enable efficient processing, effective Research and Development and excellent end-use products.