The world has fallen in love with silky, smooth and creamy foams!

The explosive emergence of foam-forming devices such as the Hotel Chocolat Velvetiser for chocolate drinks, the NitroSurge for Guinness and the Nespresso Vertuo coffee machine is testament to how consumers value the textures foams deliver. Prior to this, Foamburst shower gel, foaming cleansers and micro-foamed flat white coffee have all become well established; popular, not least, for the silky, smooth and creamy sensory experiences they deliver.

Characterising foams

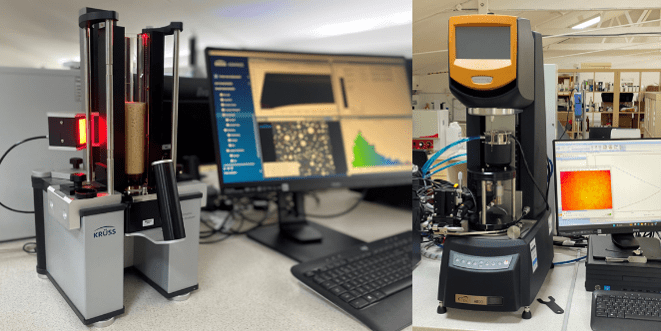

Using a combination of dynamic foam analysis, soft tribology and rheomicroscopy, we characterised the impact of foam bubble size distribution on key properties that contribute to the sensory experience of foamed products.

Dynamic foam analysis: The characterisation of foamability, foam stability and, of most relevance in this study, foam structure.

Soft tribology: The measurement of friction and lubrication of soft, typically physiological, surfaces.

Rheo-microscopy: The combination of rheology and microscopy to obtain simulataneous imaging and physical measurements.

Foam texture, deconstructed

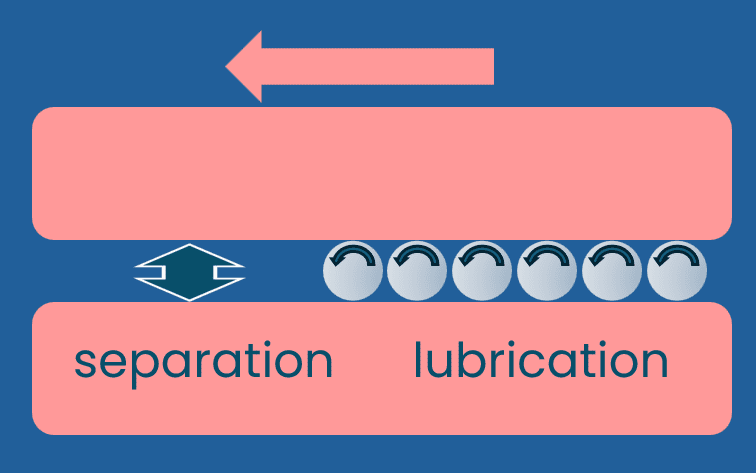

Foams deliver silky, creamy or smooth sensory experiences in two ways:

Firstly, they maintain separation of surfaces. This could be separation of the hand and skin in the case of a shower gel or cleanser, the fingers and hair with shampoo or the tongue and palate in the case of a beer or coffee.

Separation of surfaces limits the tactile perception of one surface feeling the texture of the other. This tactile-masking ability is seen in other materials. The slimy feel of, for example, raw egg white, results partly from the viscoelastic cushioning gel maintaining separation of surfaces, in addition to the low sliding resistance contribution from the egg white’s low viscosity.

In the case of foams, it is considered that those with smaller bubble sizes, and subsequently higher internal (or “Laplace”) pressures may deliver better support against the squeeze forces as surfaces approach, thereby maintaining separation.

Secondly, foam bubbles may also offer a rolling lubrication mechanism, allowing surfaces to slide easily in relative motion. This rolling lubrication may also be impacted by the bulk or interfacial shear viscosity of the liquid phase.

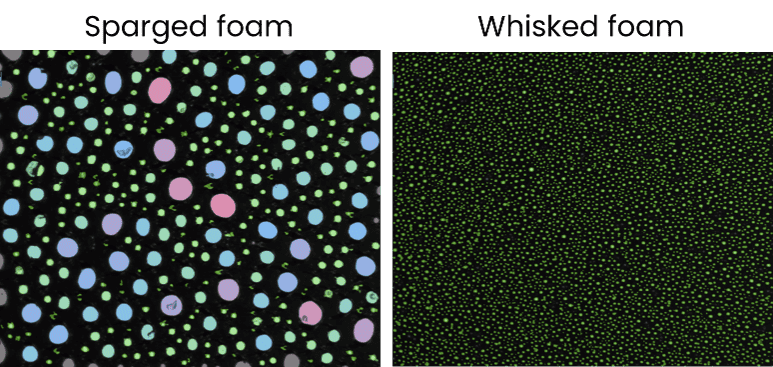

Foam generation and analysis

To investigate the impact of foam structure on lubrication and separation we chose a single liquid, an aquafaba egg alternative, from which we generated two foams of varying bubble size distributions. The foams were generated and characterised on a DFA100 Dynamic Foam Analyser (Kruss Gmbh), using both a sparging method, where gas is forced through a filter in the base of the column of liquid, and a high-speed whisking approach using a rotating attachment. The foam analyser enables imaging of the foam structure (figure 2) and quantification of size distribution.

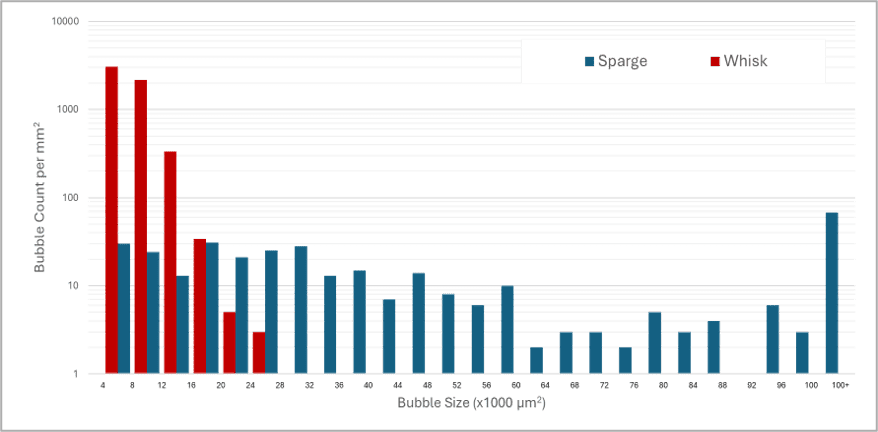

The marked difference in size distribution across the two foams is clearly seen in figure 3.

Foam tribology measurements

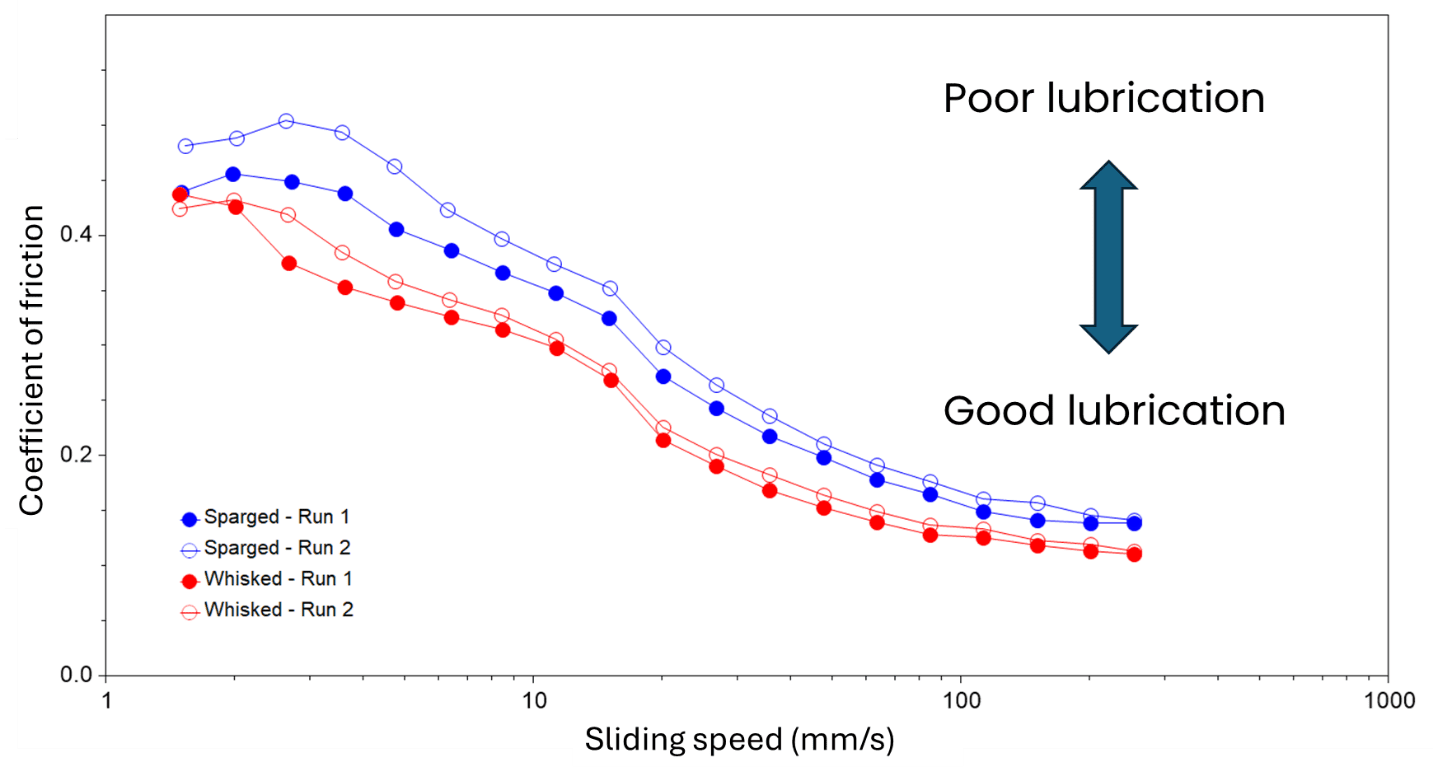

Using a custom-built tribology accessory fitted to a Discovery Hybrid rheometer (TA Instruments) we obtained tribological fingerprints (also known as Stribeck curves) of coefficient of friction across a range of sliding speeds (figure 4). Coefficient of friction is the ratio of sliding force to load force, lower values indicating better lubrication.

The tribology measurements clearly demonstrate that the whisked foam lubricates the tribo surfaces significantly better than the sparged foam, with the rolling lubrication of small, hard bubbles being the suspected mechanism at work.

Surface separation

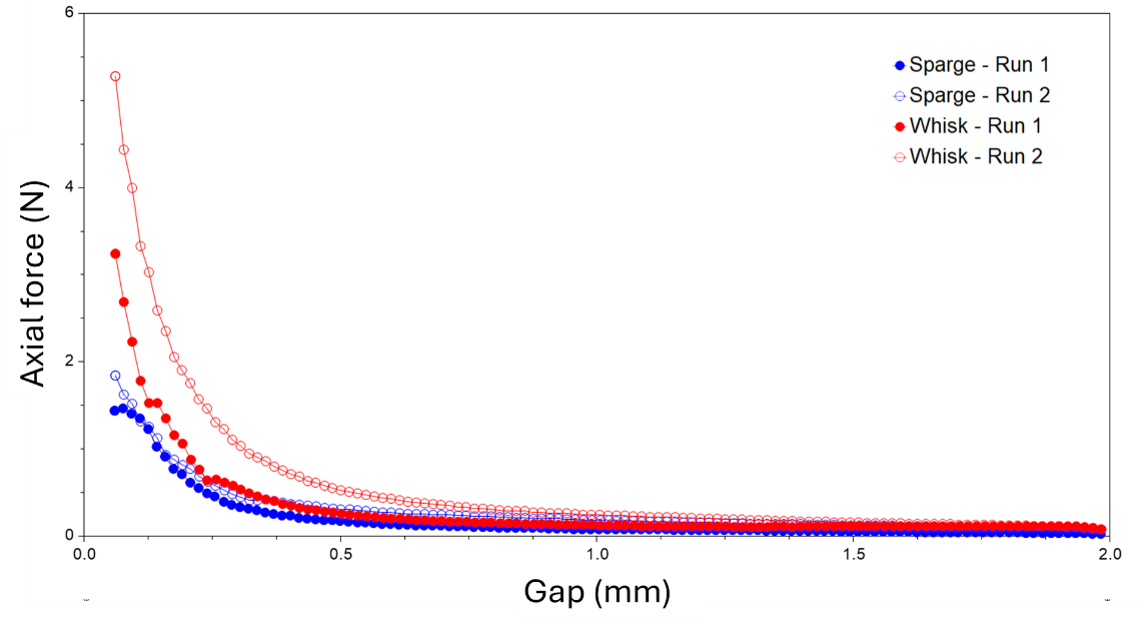

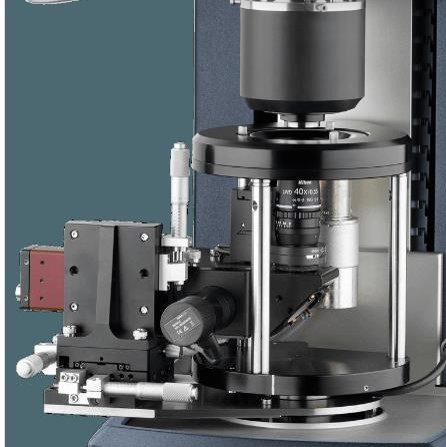

In order to capture and compare the surface separating ability of the foams we performed a compression test between the plates of a rheometer, operating in a squeeze flow mode, from a 2mm gap down 50 microns. To monitor changes to the bubble morphology throughout the compression, the rheometer was fitted with a rheo-microscopy accessory (Modular Microscope Accessory, TA Instruments).

Figure 5 clearly reveals that the whisked foam, with its abundance of smaller sized bubbles, resists the compression significantly more than the sparged foam, suggesting the high-pressure, small bubbles would contribute to the separation of surfaces.

Rheo-microscopy

Rheo-microscopy entails capturing live images of a sample through a microscope objective and camera located beneath a glass lower rheometer plate. This enables the simultaneous capturing of rheological data and the imaging of structures and features that contribute to the rheology.

Shear and counter-rotation can be applied to study its effects however, in this study, no shear was imposed throughout the compression.

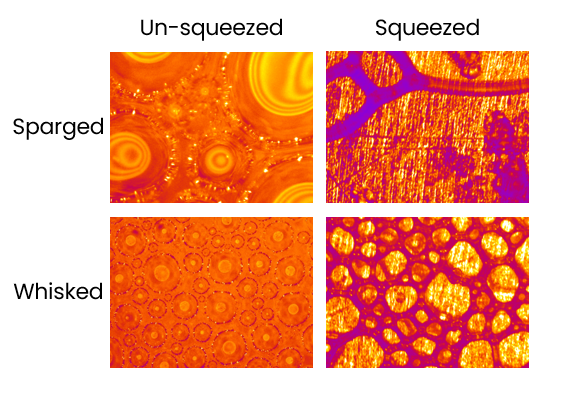

Figure 6 shows the sparged and whisked samples at the beginning and end of the compression step. The uniform small size of the whisked foam at the 2mm gap is evident, compared to the sparged sample. As the gap is reduced both foams demonstrate the loss of sphericity of the squeezed bubbles and the creation of large polyhedrons.

In summary, the combination of the techniques of foam analysis, tribology, squeeze flow rheology and rheo-microscopy are demonstrating an exciting and powerful set of tools available for researchers and product developers looking to generate sensory experiences that delight their consumers.

If you would like to discuss how these techniques can help drive your product development please don’t hesitate to get in touch.

Article by Neil Cunningham, Founder and CEO of the Centre for Industrial Rheology.

Testing and data analysis performed by Jacob Turnham, Senior Technical Specialist at the Centre for Industrial Rheology.