Relative permittivity (dielectric constant) and the dissipation factor are critical parameters used in assessing the dielectric properties of materials. These characteristics are essential in various applications, such as EV lubricants, immersion cooling fluids used in data centres, and dielectric greases.

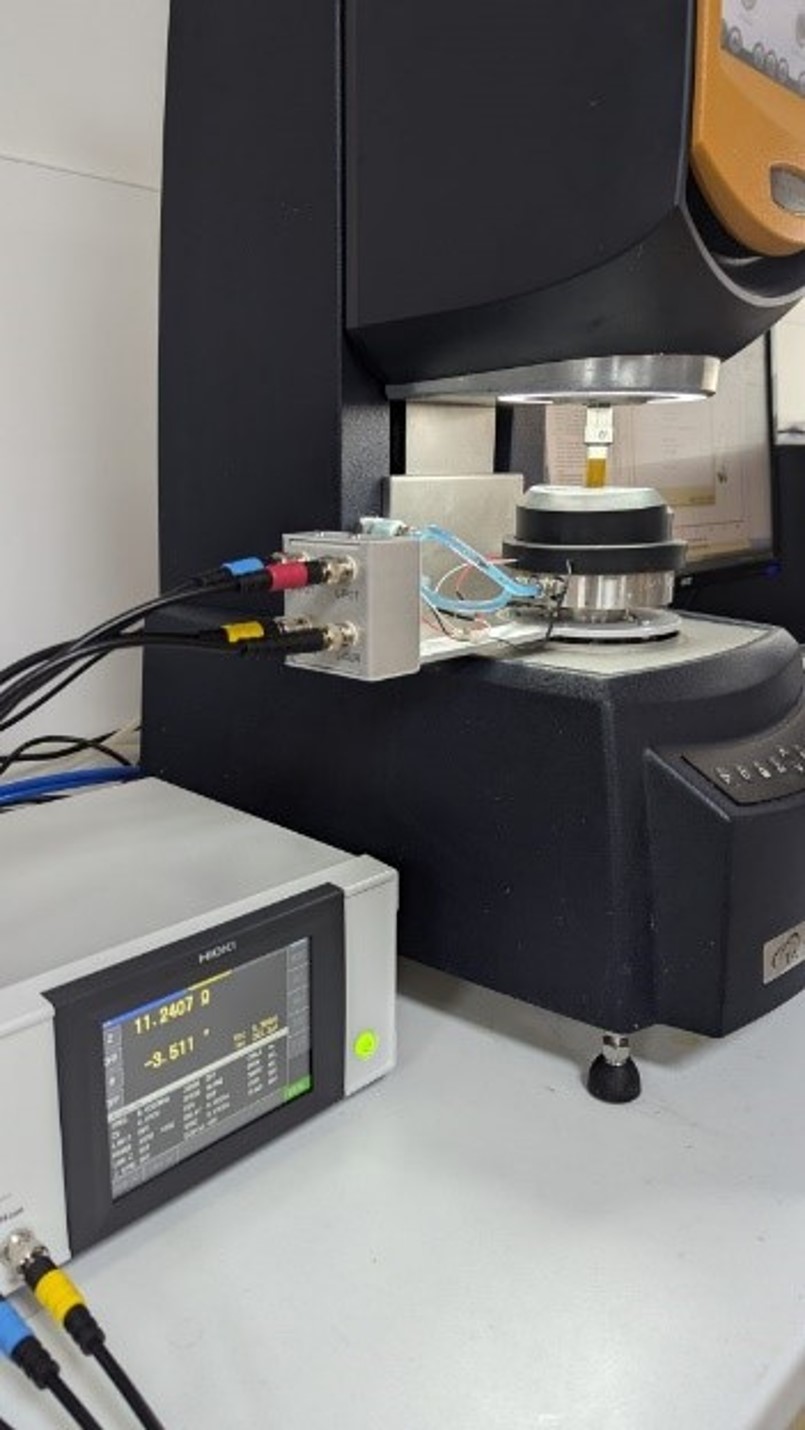

At the Centre for Industrial Rheology, our advanced materials characterisation services extend to Rheo-Impedance Spectroscopy. Impedance spectroscopy is widely used for electrical characterisation, however, Rheo-IS uniquely combines impedance spectroscopy with controlled shear and temperature conditions. This advanced method offers deeper insights into how dielectric properties can change in response to shear and thermal conditions, which traditional methods lack the ability to do.

Introduction to Relative Permittivity and the Dissipation Factor

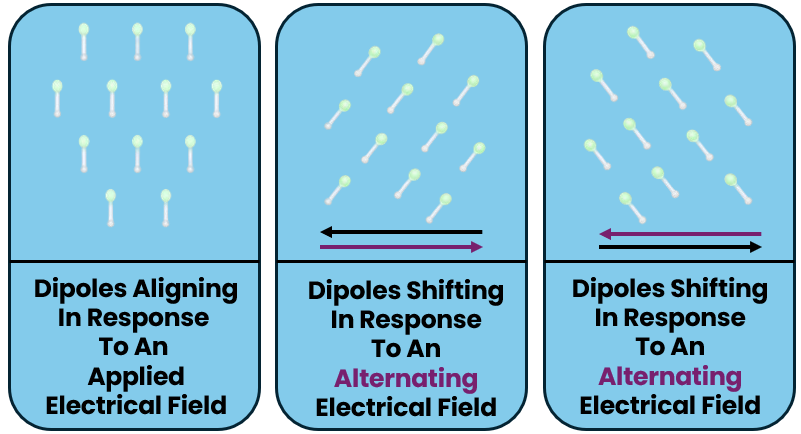

Dipoles, the separation of opposite charges, exist within a material. During impedance spectroscopy, an alternating electrical field is applied, causing dipoles to align with the direction of the field.

From the result of this behaviour, the complex permittivity can be obtained. Complex permittivity describes how much a material becomes polarised (shifting of dipoles) when an electrical field is applied.

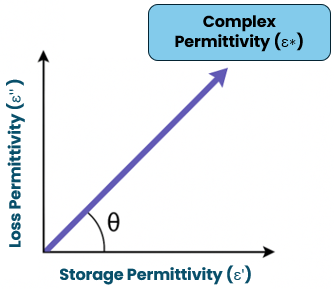

Complex permittivity consists of the aggregate contributions of storage permittivity and loss permittivity. Storage permittivity is the in-phase response of complex permittivity, representing the energy stored through polarisation. Loss permittivity is the out-of-phase response, which represents the energy dissipated as heat.

Relative permittivity compares a material’s complex permittivity to that of a vacuum and is commonly used to characterise dielectric behaviour. Materials with a lower relative permittivity typically provide better dielectric insulation as they minimise unwanted energy storage and reduce any losses.

The other key factor used in dielectric characterisation is the dissipation factor (tan δ). The dissipation factor is the ratio of loss permittivity to storage permittivity.

It quantifies how lossy a dielectric material is, that is, how much electrical energy is dissipated as heat relative to how much is stored in the material under an alternating electric field. A higher tan δ represents greater energy loss and, as such, suggests a less efficient dielectric.

Dielectric Characterisation of Greases

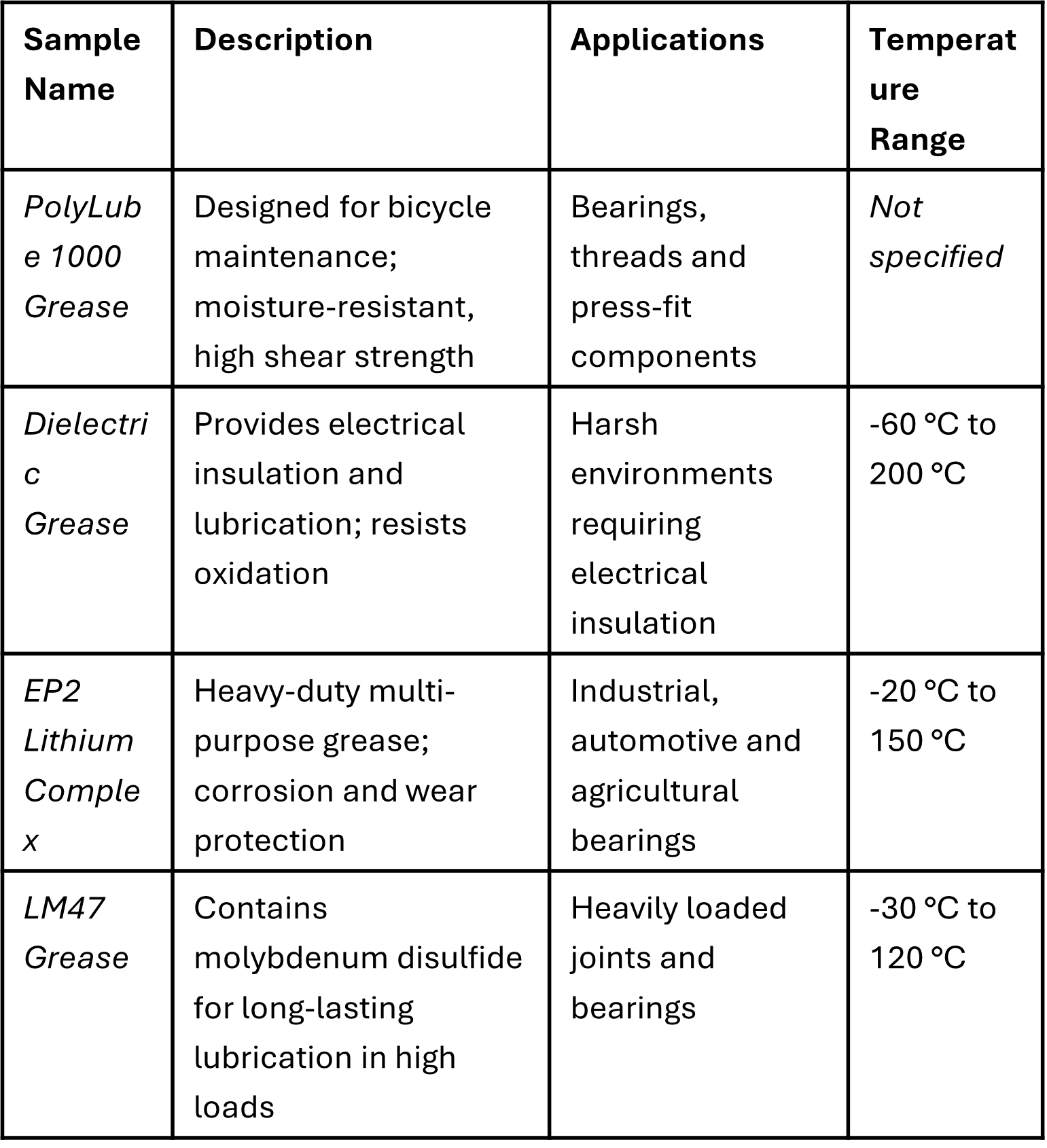

In this case study, we sought to characterise the relative permittivity and dissipation factor of various greases.

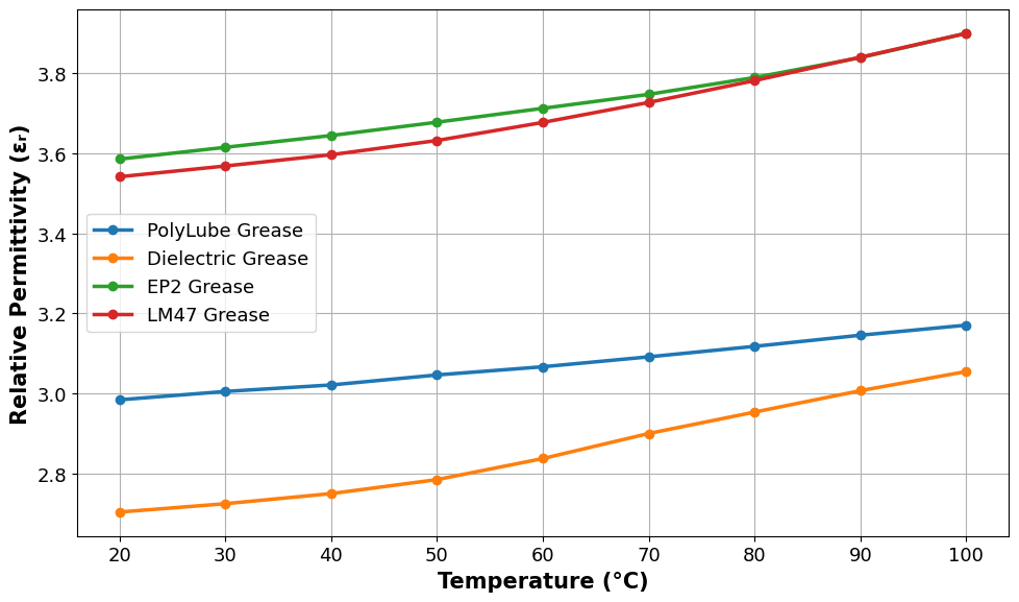

Relative permittivity and the dissipation factor can vary with the dielectric frequency applied. For simplicity, we measured these variables at a fixed frequency of 1 kHz across a temperature range of 20°C to 100°C to investigate thermal effects.

Relative Permittivity of Fresh Greases

The results show that increasing temperature increases the relative permittivity of all greases. The dielectric grease consistently exhibits the lowest relative permittivity when compared to the other greases over the temperature range tested.

Figure 5 shows how the rate of change of relative permittivity changes at each temperature. The results show that the PolyLube grease has the most thermally stable relative permittivity across the samples tested. This highlights that there may be opportunities to optimise formulations for more thermally stable dielectric properties.

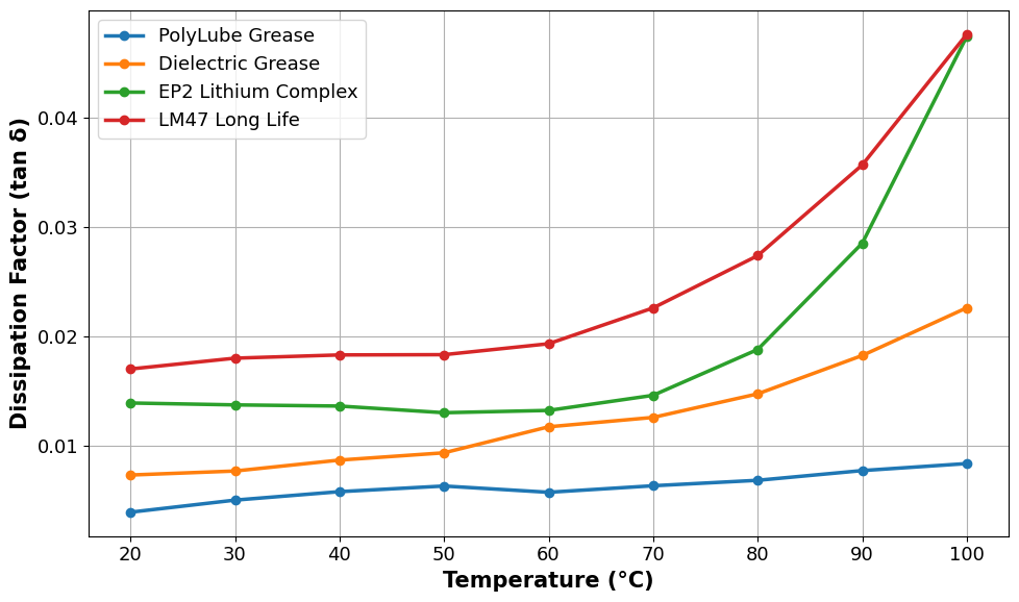

Dissipation Factor of Greases

Interestingly, the PolyLube grease consistently exhibits the lowest dissipation factor across the temperature range tested, suggesting that less energy is dissipated as heat under the applied electrical field.

Overall, the dielectric grease offers a lower relative permittivity, making it advantageous where minimal capacitive influence is desired. Meanwhile, PolyLube’s consistently low dissipation factor points to reduced dielectric loss, which is a strength in thermally sensitive or high-voltage applications. The optimal balance will depend on the specific application.

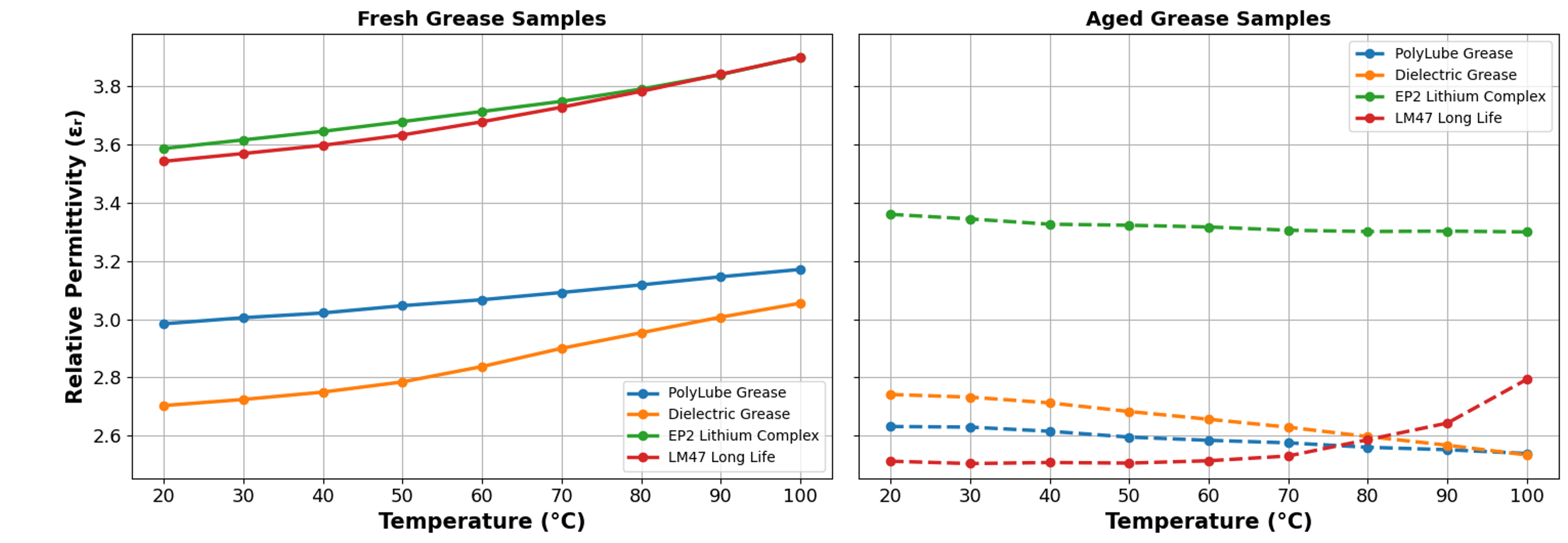

Fresh vs Aged Comparison

In addition to characterising the greases when they are freshly dispensed, we also sought to characterise their electrical properties once they had been subject to thermal ageing at 120°c for 5 days, leaving them open to any potential oxidation or thermal degradation effects.

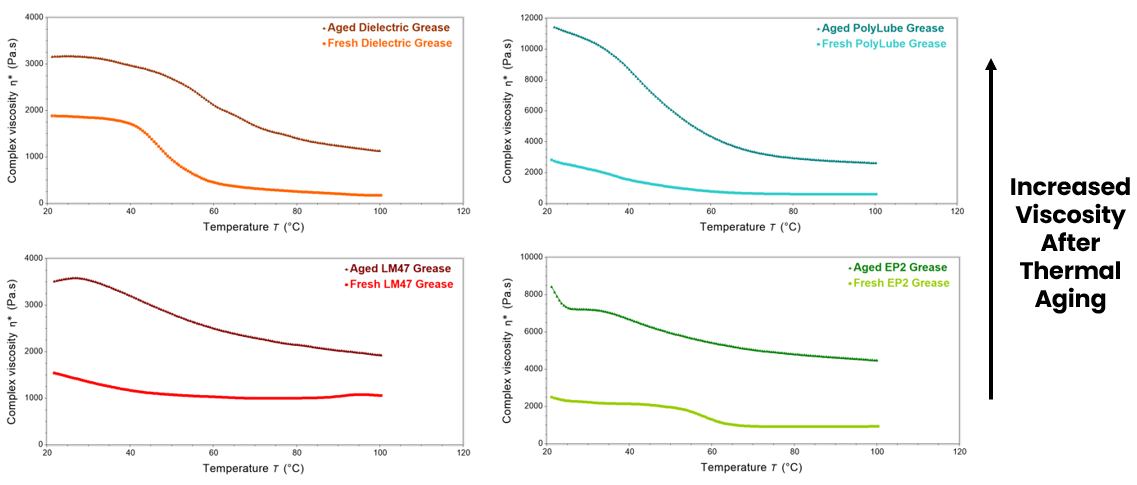

The results show that the aged samples exhibit a lower relative permittivity compared to the freshly dispensed greases. At face value, this reduction in relative permittivity suggests improved dielectric performance. However, this also needs to be interpreted in the context of any structural changes that may have occurred to the greases due to thermal ageing. To obtain insights into any changes to the structure of the greases, we conducted our routine oscillatory rheological techniques to obtain the complex viscosity of the fresh and aged samples to see if any structural changes had occurred during thermal ageing.

The results show that each aged grease has undergone an increase in its viscosity, indicating structural hardening. This significant increase in viscosity across all samples is generally undesirable, with firmer greases potentially leading to increased friction. From a thermal stability perspective, the increase in viscosity suggests structural changes, such as oxidation, have occurred.

With this added context, the lower relative permittivity may be a consequence of structural hardening. As the greases become more solid-like after thermal ageing, the internal mobility of dipoles may be reduced. These dipoles, therefore, may be less responsive when an electrical field is applied, reducing the loss permittivity.

While the dielectric performance has improved, the material has become too stiff to function effectively as a grease. This highlights the importance of evaluating the dielectric properties of a sample with complementary rheological analysis.

Summary

Rheo-IS is a very new technique here at the Centre for Industrial Rheology. This case study has shown how it can be used to capture dielectric properties as a function of temperature, as well as rheological properties. In addition to this, Rheo-IS can also be used to monitor how these properties change under the application of shear. This allows a deeper understanding of how the dielectric properties of a formulation can evolve under more realistic, real-world conditions, where both temperature and shear rate can vary. Such understanding will no doubt be critical in research and development of dielectric fluids such as EV lubricants and immersion cooling liquids for data centres.

While we have employed Rheo-IS to explore the dielectric properties of greases in this article, we have also used it to probe the microstructure of greases. Read our article on thermal ageing of greases to learn more about the additional insights that rheo-impedance spectroscopy can offer.

If you want to discuss this technique with us and how it may be able to help your product innovation, do not hesitate to contact us.