Contact Angle Testing/Analysis

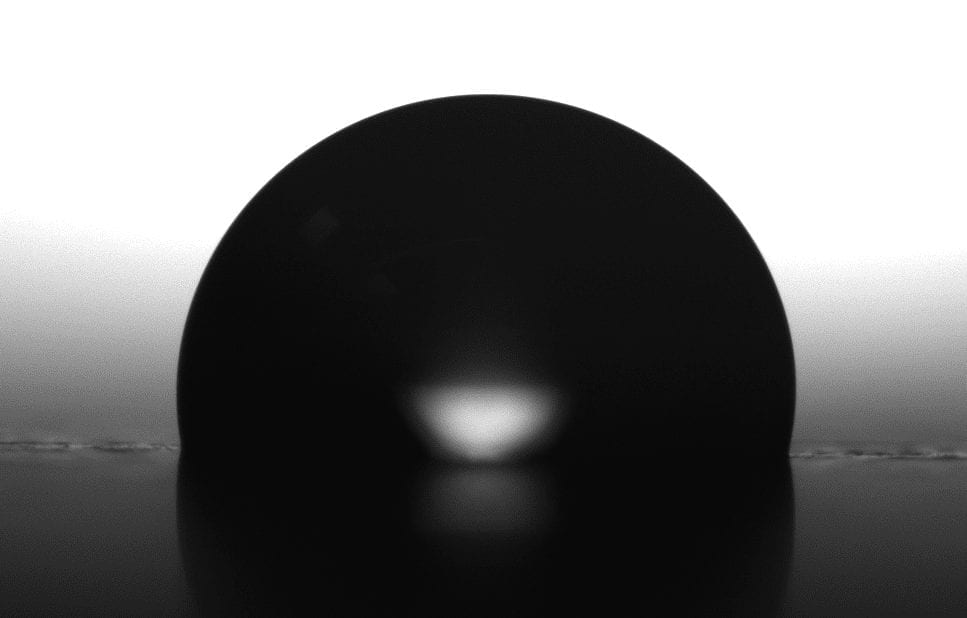

Sessile drop analysis entails measuring the angle at which a small drop of liquid contacts a surface. Contact angle ranges from 0 degrees for complete wetting of a surface to 180 degrees for complete non-wetting. In the case of water on a surface, a contact angle of less than 90 degrees characterises the surface as hydrophilic and hydrophobic if the contact angle exceeds 90 degrees. Contact angle measurements are typically used to measure the wettability of a known surface through the use of drops from various liquids under test. Alternatively, by applying known liquids to an unknown material, the surface energy of that material can be quantified.

Get a quick quote

Dynamic Contact Angle Testing/Measurement Methods

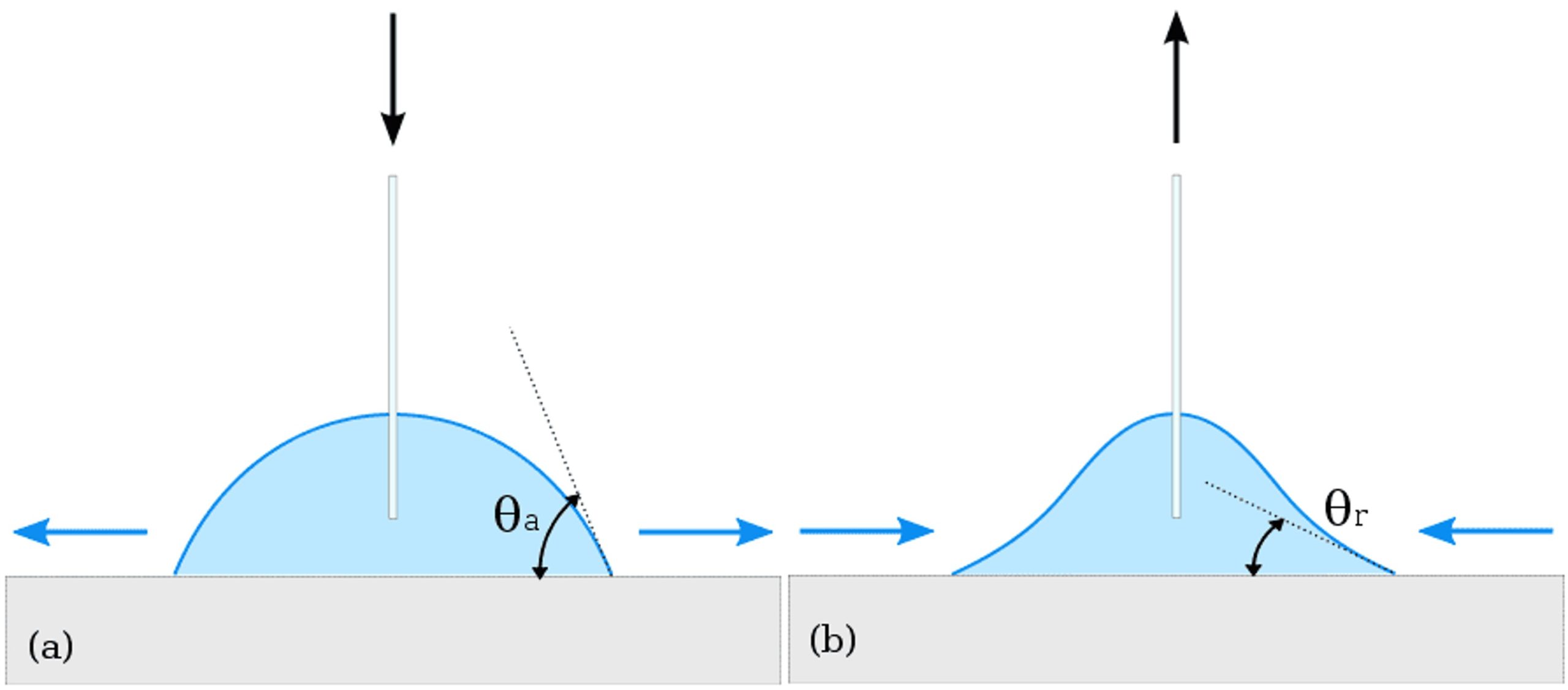

Dynamic contact angle measurement is the term given to the quantification of advancing and receding contact angle. Advancing contact angle is associated with wetting fresh, previously un-wetted surfaces. The receding contact angle is that angle associated with the dewetting of a surface, as the liquid front recedes. The difference between advancing and receding contact angle is known as hysteresis and can inform about the uniformity of surface treatment, its roughness and cleanliness.

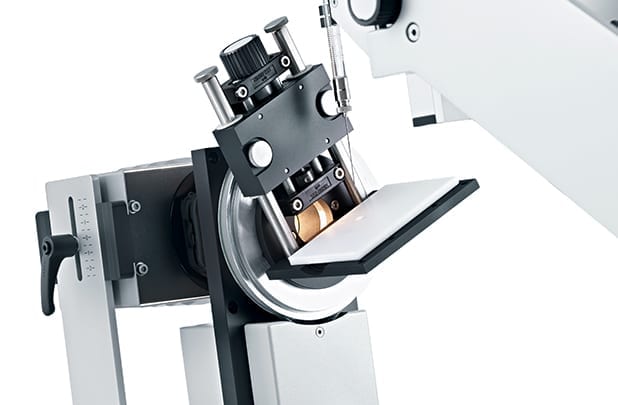

Dynamic contact angle measurement is performed in two ways: through altering the volume of a sessile drop by dosing liquid to form a maximum advancing angle (Figure a) and removing liquid to form a minimum receding angle (Figure b), or by the use of a tilting table (below) which measures the angles at the front and rear of a drop at the incipient of movement. The tilting table method employed here can also be used to measure the “roll off angle” which provides a simple measure of the draining ability of a treated surface.

Dynamic Wetting Measurement

Wetting is the result effect of the adhesive forces between a solid surface and a liquid drop and the cohesive forces within the liquid drop. Strong liquid-solid surface cohesive forces minimise the contact angle, while stronger liquid-liquid adhesive forces lead to an increased contact angle. The dynamic wetting measurement can be recorded using high speed imaging to capture the contact angle at rapid intervals subsequent to the placing of a drop. This can inform on the rapid adsorption of surface active entities or on situations where significant interaction, either chemical or physical, with a surface may occur. The main commercial applications of this technique are:

- Determining surface functionality.

- Development of self-cleansing films, fabrics and glass surfaces.

- Measuring the spreading rate of various liquids on a surface.

Contact us now to discuss your specific challenges.