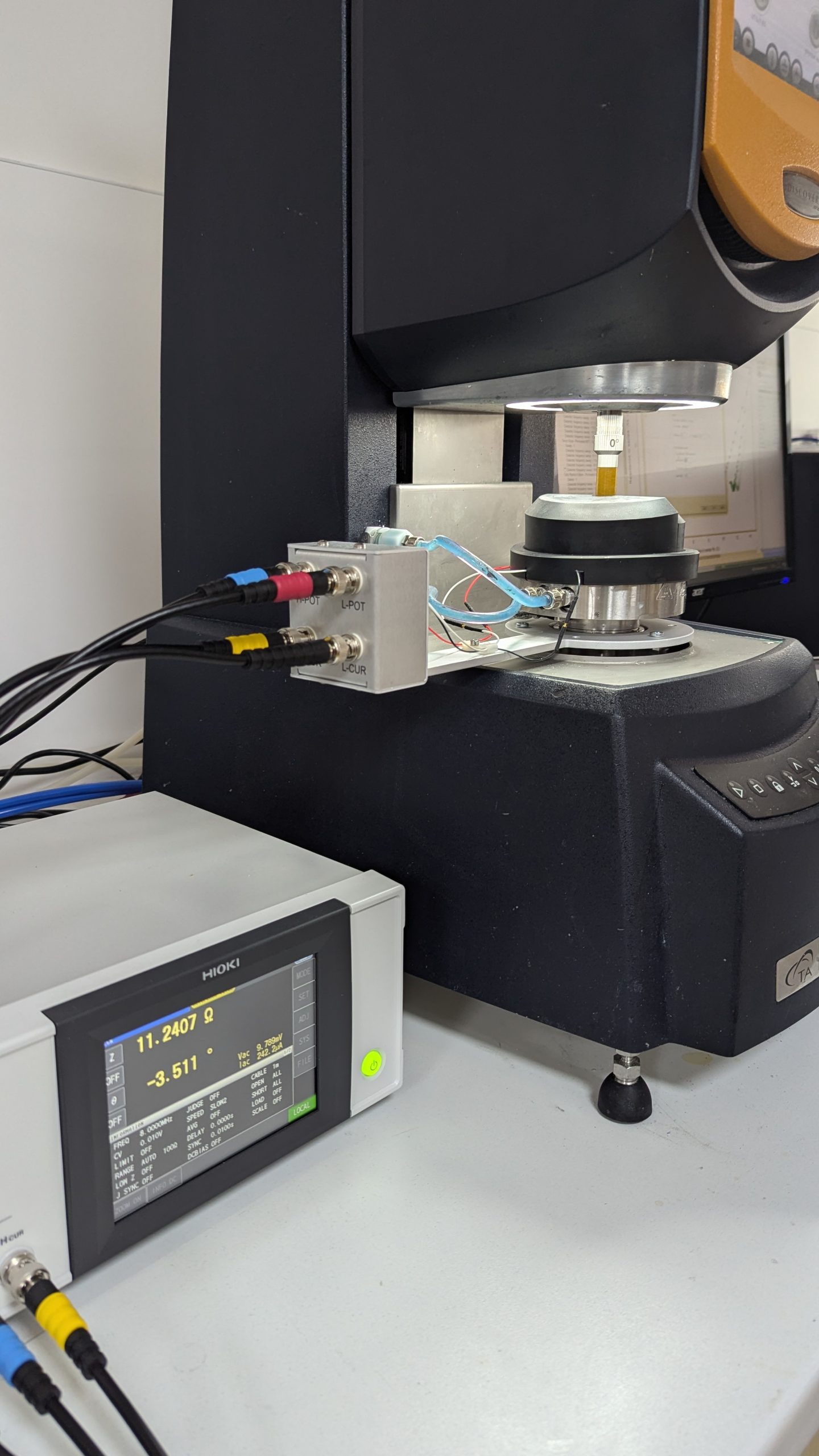

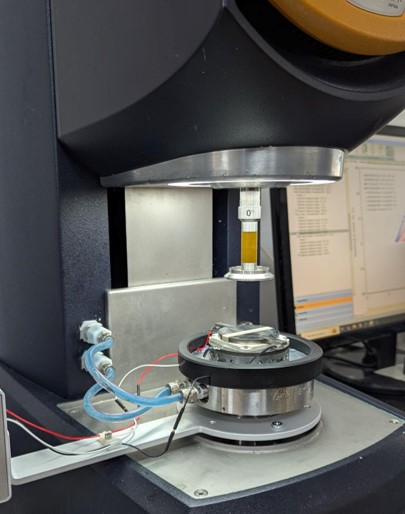

Rheo-Impedance Spectroscopy is a novel development that combines two powerful material characterisation approaches: rheological profiling and electrochemical impedance spectroscopy. The ability to simultaneously capture microstructural information from both techniques, whilst changing shear and temperature conditions, provides formulators with a potent capability in their measurement toolkit.

In this study, we conducted rheological testing on market-leading shampoos and conditioners to analyse their viscoelastic properties. These measurements provided valuable insights into properties such as the complex modulus, yield point, and whether samples were elastic or viscous dominant under different conditions. It was observed that some samples obtained very similar rheological profiles, prompting us to explore ways to differentiate between these samples further.

Introduction to Rheo-Impedance Spectroscopy

Electrochemical Impedance Spectroscopy (EIS) can be used to investigate the microstructural and electrochemical properties of materials. By applying an alternating current and measuring the resulting impedance, EIS provides insights into the electrical and structural characteristics of materials. However, traditional EIS measurements are performed under static conditions, limiting the understanding of how shear may affect the microstructure of formulations. This can be particularly significant in products such as shampoos and conditioners, where the microstructure may change under conditions that reflect real-world use, such as application into hair. These changes may directly impact product performance and a consumer’s experience of a product.

Rheo-Impedance Spectroscopy overcomes this limitation by integrating standard EIS measurements under both controlled shear and temperature conditions. By applying controlled shear rates and temperatures, Rheo-IS can capture subtle changes in microstructure, such as breakdown during shear or recovery after shear, which remain unexplored with standard EIS measurements.

Viscoelasticity of Shampoos and Conditioners

We identified market-leading shampoos and conditioners and sought to evaluate their structural characteristics. The samples tested were:

- Bed Head Resurrection Shampoo – designed for damaged hair

- TRESemmé Lamellar Shine Conditioner – known for its lamellar technology

- L’Oréal Elvive Colour Protect Conditioner - likely featuring similar lamellar structures to TRESemmé

To thoroughly investigate their structural properties, we performed oscillation measurements on each sample to obtain detailed rheological insights.

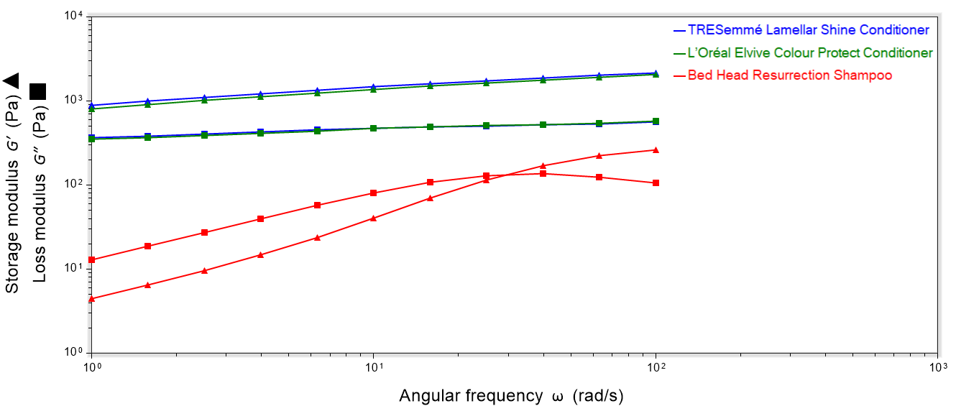

Figure 2 presents the data obtained from the oscillation frequency sweep, where the complex modulus has been separated into storage and loss modulus to enable clear differentiation between elastic and viscous behaviour. The Bed Head shampoo can be seen to relax into a more viscous-dominant structure at lower frequencies, displaying classic time-scale dependent viscoelastic properties. However, at higher frequencies, it undergoes a typical crossover transition, becoming increasingly elastic dominant. In contrast, both TRESemmé and L’Oréal conditioners exhibit a well-defined elastic dominant structure. It can be useful to identify the yielding behaviour of these elastic dominant samples through an oscillation stress sweep.

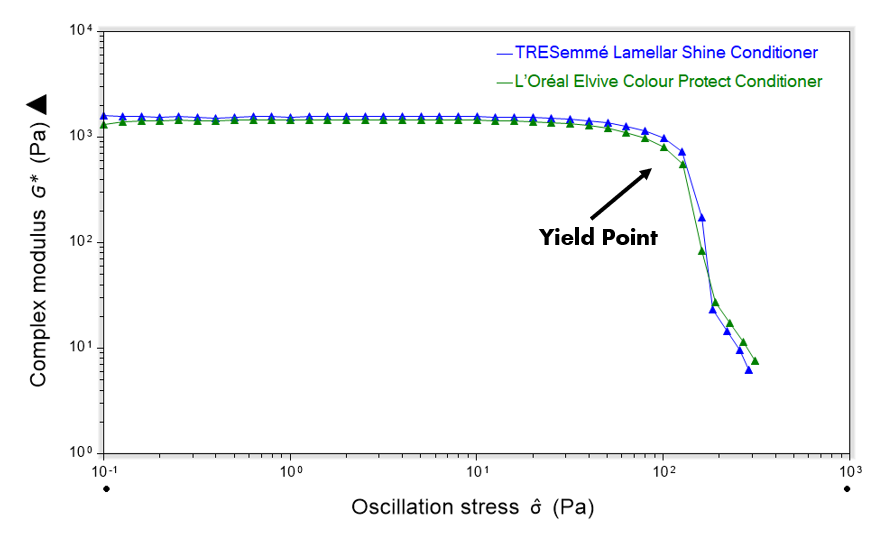

Data obtained from the oscillation stress sweep can be seen above in Figure 2. Here, we look at the complex modulus, which quantifies a material’s overall resistance to deformation. An important observation from this data is the distinct yielding behaviour observed at higher stresses. The yield point indicates the transition point from which a material shifts from elastic (recoverable) deformation to plastic (permanent) deformation, with both conditioners yielding at around 100 Pa.

The results from the oscillation sweeps showcase the wealth of insights rheological testing can offer that simple viscometry alone cannot offer. However, the results show that the two conditioners are not easily differentiated based on the rheological data alone. This raises the question of whether more subtle structural differences between these formulations may exist.

Rheo-Impedance Spectroscopy for Conditioners

Where further differentiation is needed, we employed our Rheo-IS methods to see if this highly sensitive technique was able to capture any microstructure differences between the samples.

Utilising Rheo-IS, impedance data, which describes the opposition to an alternating current, can be obtained. It is made up of resistance, which is the opposition to any electrical flow. A higher resistance indicates a more structured sample, as more opposition to flow is observed. Conversely, a lower resistance suggests less structure, resulting in less opposition to flow.

Reactance is the additional opposition to electrical flow where capacitance is present, which arises from a sample’s ability to store charge temporarily. At interfaces within a sample such as a conditioner, a separation of charges naturally occurs, forming an electrical double layer. This double layer functions similarly to a capacitor, temporarily storing flow. As such, reactance data can provide insights into the extent and integrity of interfaces within a sample. Through this data, a Nyquist plot can be obtained.

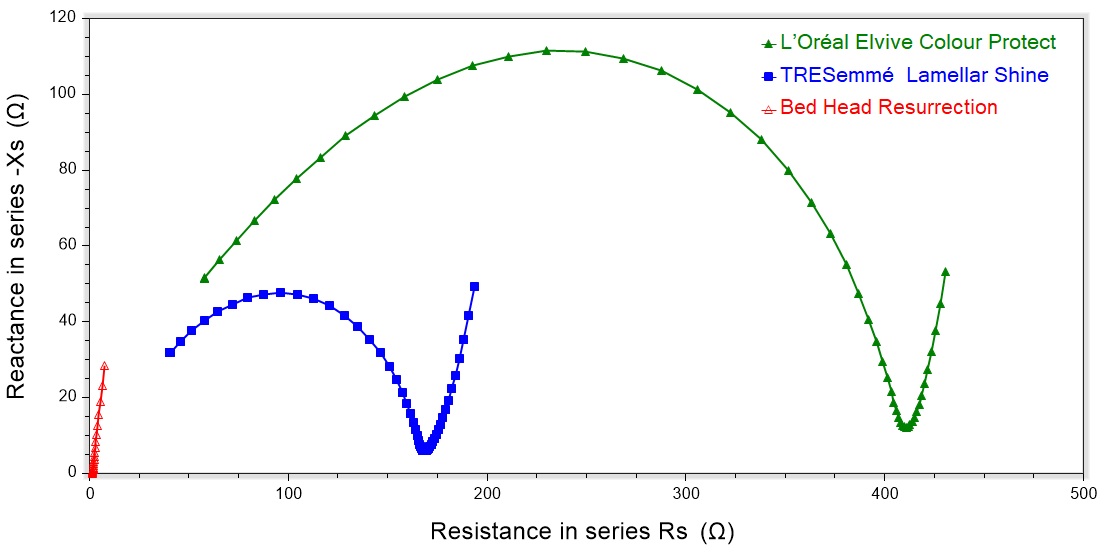

The Nyquist plot obtained at low shear conditions for both conditioners shows that there is a significant difference in impedance spectra. This highlights that Impedance Spectroscopy can successfully pick up subtle microstructural differences. Interestingly, the data for the Bed Head Shampoo does not follow a typical Nyquist plot, potentially suggesting that there is minimal structure within the formulation. We can extend this analysis by looking at microstructural changes as a function of shear rate, something which traditional EIS methods lack the ability to do.

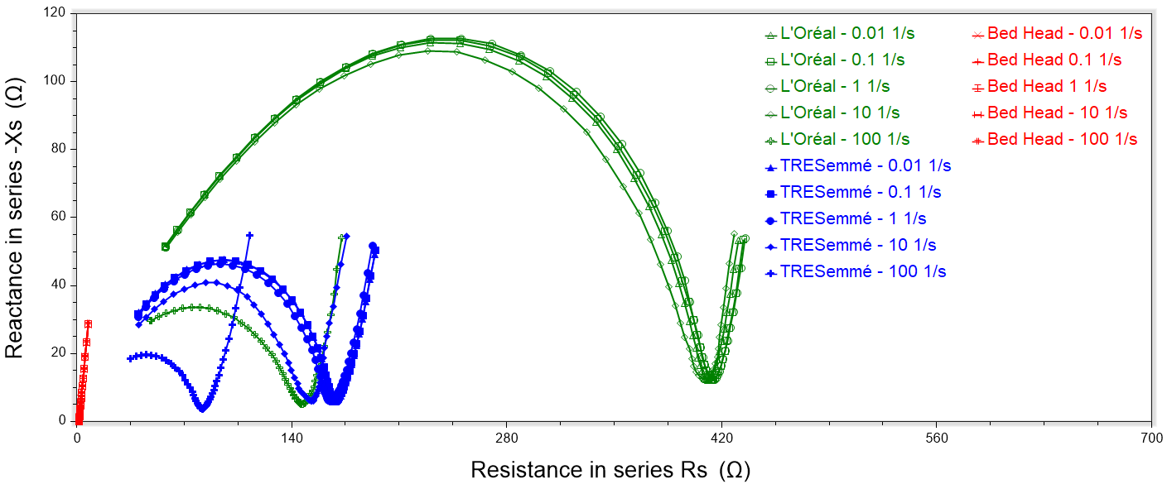

When changing shear rates from 0.01 s−1 to 10 s-1, there is a negligible change in impedance spectra for the L’Oréal conditioner, indicating that the microstructure remains stable within this shear range. However, at 100 s-1, L’Oréal displays a significant shift in impedance spectra, becoming notably similar to TRESemmé’s impedance spectra observed at 10 s-1. This suggests that at high shear conditions, the microstructure of L’Oréal begins to resemble the structural characteristics of TRESemmé.

TRESemmé displays a continuous shift of impedance spectra toward lower resistance values with increasing shear rate. Although differences between shear rates of 0.01 s -1 and 1 s-1 are small, a pronounced shift is apparent at 10 s-1, becoming even more pronounced at 100 s-1 . Despite this continuous decrease, the overall change in impedance for TRESemmé across the shear rate range tested is smaller compared to the substantial shift observed for L’Oréal at 100 s-1 . Bed Head shampoo shows no shear dependent shift in impedance spectra, again suggesting minimal structure.

Summary

Through standard rheological measurements, both conditioners exhibited nearly identical viscoelastic properties. However, employing Rheo-IS revealed clear microstructural differences between the two formulations, especially under varying shear conditions.

The results from this study demonstrate Rheo-IS’s sensitivity and capability in identifying critical microstructural differences. We are excited with the initial results from our newly acquired Rheo-IS kit and are actively exploring its full potential. If you want to discuss our capabilities further, do not hesitate to contact us.