Capillary rheology measurements add a powerful capability to the toolkit of characterisations available for product developers and process designers. Our capillary rheometer enables the measurement of shear viscosity and extensional viscosity, extrusion properties and mobility from ambient temperature up to 400°C.

What is a capillary rheometer?

A capillary rheometer is a tool for measuring viscosity and other rheological properties of a fluid, by driving a sample from a barrel into and through a small tube, the capillary. The volume flow rate through the capillary is determined by the speed at which a plunger forces the sample from the barrel into the capillary. From a knowledge of the volume flow rate and the bore of the capillary, shear rate can be calculated. A pressure sensor positioned in the barrel enables the measurement of the pressure drop across the capillary. From pressure drop, capillary diameter and length, shear stress can be calculated. The viscosity at any defined shear rate is then calculated from the ratio of shear stress to shear rate, following various corrections.

Why use a capillary rheometer?

Capillary rheology measurements are desirable for various reasons, including:

High shear rate viscosity measurements

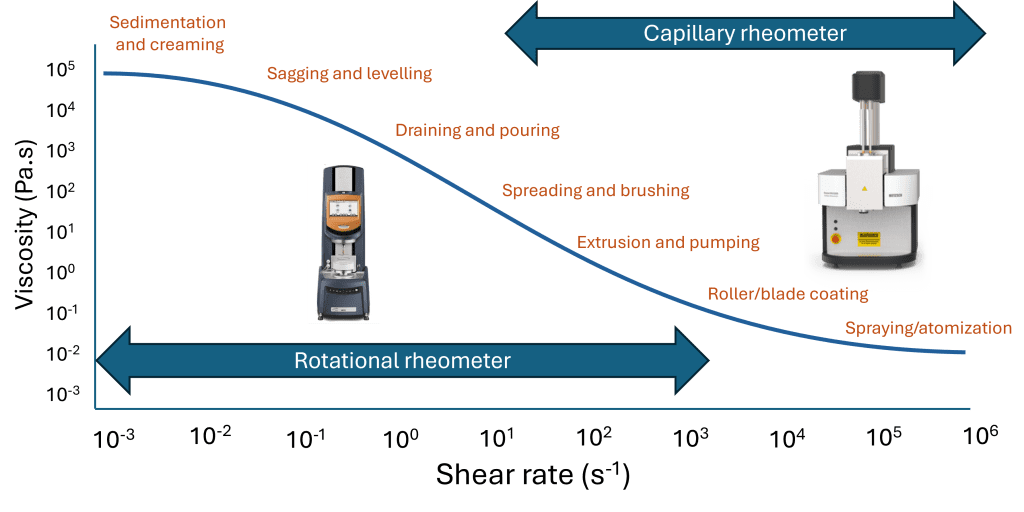

Capillary rheometers enable the measurement of viscosity at far higher shear rates than those obtained through rotational methods employing cone/plate, parallel plate and concentric cylinder measuring systems, where centrifugal sample expulsion and secondary flows limit applicable shear rates. Whilst many rotational methods will top out at shear rates of 5000s-1 or so, capillary rheometers can regularly achieve shear rates in excess of 100 000s-1 throughout measurements.

“Difficult” samples

Rotational methods are often beset with measurement artifacts. Notably with pastes and waxy samples, cone/plate and parallel plate methods suffer from sample fracture and edge failure, where the sample between the plates effectively splits into an upper and lower sample mass, with a pronounced gap at the perimeter of the sample and a highly-localised shear field that does not extend through the entire sample. Capillary rheometers can largely avoid these issues.

Extensional viscosity

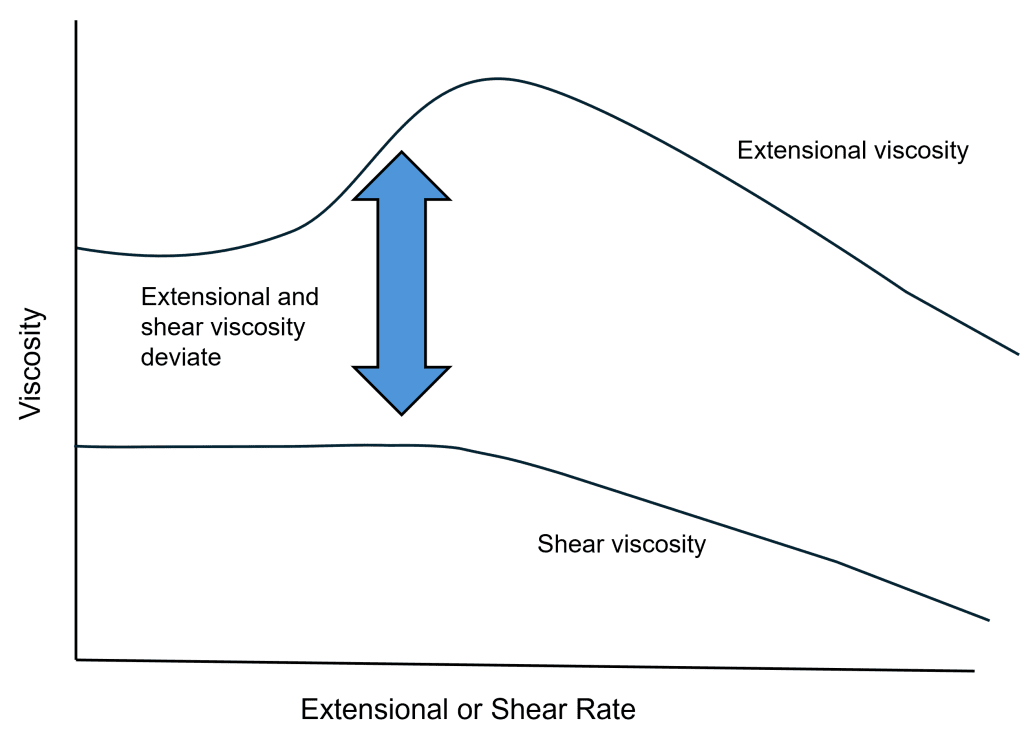

Twin bore capillary rheometers enable the measurement of extensional viscosity. Extensional flows, despite their ubiquity, are measured far less frequently than shear flows. Anytime a fluid layer or stream is stretched – such as when entering an orifice, pinched into droplets under atomisation or squeezed between approaching surfaces – extensional or elongational flows occur. Extensional, or elongational, viscosity is the resistance to such flows. With Newtonian liquids the relationship between extension and shear viscosity is a simple 3:1 ratio (the Trouton ratio) however significant deviation from this ratio occurs with, for example, molten or dissolved linear polymers, where shear thinning coincides with extensional thickening.

Knowledge of these relative extensional and shear behaviours can predict processing, filling, handling and application properties. Capillary rheology, in particular, is valuable for characterising materials that are subjected to high shear processes such as extrusion, injection moulding, and spraying. Our experts utilise their extensive experience with a wide range of materials from all industries to support your product development and processing challenges.