![]()

Sustained release drugs or modified release drugs, take advantage of rheology to help alter the release kinetics of their active pharmaceutical ingredient API. The Centre for Industrial Rheology provides materials characterisation services, training and consulting for businesses looking to get a complete understanding of their products, or needing to provide characterisation data for new drug submissions.

Sustained release drugs or modified release drugs, take advantage of rheology to help alter the release kinetics of their active pharmaceutical ingredient API. The Centre for Industrial Rheology provides materials characterisation services, training and consulting for businesses looking to get a complete understanding of their products, or needing to provide characterisation data for new drug submissions.

Whether you are looking to understand how temperature can affect the physical handling behaviour of your thermo-sensitive topical product, the settling or sedimentation behaviour of your suspension or whether you simply wish to benchmark similar products to better understand how they are similar (or differ!) we have decades of experience with some of the worlds biggest brands, helping solve a variety of industrial challenges.

From viscosity measurements, yield stress, temperature dependence, thermal conductivity, interfacial tension – our lab is well equipped to deal with a myriad of material types.

If you would prefer to have a discussion about how to utilise physical characterisation techniques to understand and improve your product, contact us now.

Some of the oldest and perhaps most well known examples of modified release drugs are that of topical creams and while injectables may not be the most pleasant route for administration, they offer significant benefits in directing an API to the site of action and bypassing physicochemical barriers such as the skin or high acidity of the gastrointestinal tract.

Candidates for modified release injectables often include poorly soluble APIs, treatments requiring therapeutic concentrations of API to be maintained for a prolonged period of time or the treatment may simply be highly unpleasant to administer repeatedly.

Polymers and biopolymers are exciting new materials being developed to address these challenges, and effective characterisation of their inherent physical properties can help inform formulators on the best way to use them. Emulsification, encapsulation, complexation, and gelation are all potential routes for modifying pharmacokinetics, with rheology helping to compare formulations and identify potential candidates with desirable physical profiles.

Thermal Oscillatory Testing : Characterising physical changes related to temperature

Thermal Oscillatory Testing : Characterising physical changes related to temperature

Viscosity profiling is not the best test for looking at structural changes to a sample. The shear applied during a viscosity test may damage or even destroy the very structure that is being formed. In this case oscillatory testing, whereby the sample is ‘wobbled’ very gently back and forth and either stress or strain is measured, is minimally disruptive and provides more relevant information for structural changes. For thermally reversible gelation, it is possible to choose a low oscillation stress/strain and sweep the temperature up or down to identify the material’s response to temperature, and whether multiple sweeps cause a deteriorative effect.

Thermosensitive Injectable Polymer Hydrogels

Materials which can reversibly gel upon the application of increased temperature have exciting uses in therapy since they can be easily manipulated and delivered to a target tissue, then due to surrounding heat transfer from the body, will gel. This gelation causes the material to resist clearance from the body, prolonging its presence at the target site and altering the release kinetics of the API. Many thermosensitive polymers such as poly(N-isopropylacrylamide) (PNIPAM) gel at physiologically relevant temperatures (in this case 32°C).

Encapsulation and controlled release – Temporary protection from the environment

Encasing active pharmaceutical ingredients within a protective material to improve delivery is a tried-and-true method for modifying not just the potential administration route, but improving palatability, biocompatibility or mechanisms for release. The sustained release of API is made possible by designing the capsule to degrade under specific conditions. Capsule wall material, or coating material can vastly affect the release profile of these drugs at any scale – indeed many gastrointestinal drugs include a bio or mucoadhesive polymer coating to promote adhesion to the gastrointestinal lining and emerging therapies in injectable nanotechnology design capsules to adhere to specific tissues. At the nanoscale, many hydrophobic nanoparticles are often treated with a polymer later to render them hydrophilic and improve their solubilisation.

Drug complexes – Environment triggered release of active pharmaceutical ingredients

Drug complexes are most often APIs that have been crystalised or with a chemical component such as a salt or polymer (or both!) that disconnects, solubilises, or uncovers active sites when exposed to physiological pH, water activity or temperature. While this may indeed modify and/or sustain release of API to target tissue, ensuring that the particulates are homogenously dispersed, and remain suspended can prove challenging.

Emulsification – colloidal drug carriers

Many active pharmaceutical ingredients are water insoluble making their targeted delivery problematic. Emulsions have been in use therapeutically in both topical products and injectables. Like encapsulates, emulsions help sustain release of APIs by designing droplets protect their payload, and to release under a specific set of conditions (such as the droplet having been ingested by a phagocyte, or having adhering to a lipid permeable membrane), or over a period of time. Topical products such as skin creams are classic examples of emulsions which have been used to help sustain release of API over a specifc area. Skin creams are easy to use and apply, and with inspiration taken from the cosmetics industry, can be designed to be comfortable or even pleasant to use. For injectables, using emulsions can enhance the immune response to antigens, acting as an ‘adjuvant’, favoring their use for vaccine delivery.

Since emulsions can exist in many complex formats – oil in water (o/w), water in oil (o/w) or even o/w/o or w/o/w – this can give greater choice to the pharmaceutical formulator on how to design treatments which deliver APIs towards specific tissues or over specified periods of time.

Particulate Effects on Rheology

The size and quantity of particulates within a suspension can greatly affect product handling and rheology. Generally, for equal volume fractions, an increase in particle size or particle size distribution will decrease viscosity however other inter-particle forces can affect this including particle charge, shape and even elasticity. The perceived effect in an injectable is a product that can be difficult to administer (high syringe force or a change in syringe force as the plunger is depressed) or performs unexpectedly once administered (for example being carried away by the bloodstream or creating a plug).

Viscosity : Stability, Syringeability and flow resistance

Viscosity : Stability, Syringeability and flow resistance

Viscosity is a key characteristic that contributes to the physical stability of your product. A material with a high viscosity will slow the passing of particles through it, whereas a lower viscosity material may not have the same capability of being able to suspend particles. Higher viscosity materials are also more difficult to work with, providing a higher resistance when being forced to move. In this case, it is desirable to have a high viscosity when the material isn’t being made to move – a high “zero-shear viscosity”, but a low viscosity when it needs to be pumped elsewhere. Non-Newtonian materials will change their viscosity depending on the shear applied to them. Suspensions, emulsions, polymer solutions, and gels can often display a form of non-Newtonian behaviour described as “shear-thinning”, meaning their viscosity decreases as shear rate is increased. Shear thinning behaviour is sometimes confused with thixotropy, which is a time-dependent shear thinning behaviour.

The ease at which an injectable can be evacuated from a syringe (its “syringability”) is heavily affected by the viscosity of the material, and needle gauge. Narrower needles are preferred to ease discomfort to the patient, but increase the force required on the plunger, can prolong the duration of the injection (since lower flow rates are achieved) and can have a marked effect on increasing the shear applied to the injectable. For delicate injectables, this high level of shear can damage the payload encapsulates, protein structures and droplets, which can then affect the thereaputic effectiveness of the drug. A thixotropy test can be used as a proxy to investigate whether changes in the viscosity of your sample are a result of recoverable thixotropic behaviours, or potentially due to non-recoverable damage to your sample due to high shear.

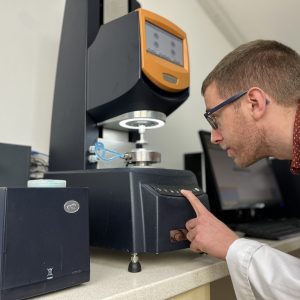

Using our high powered rheometers, we can measure the viscosity of your sample at zero shear and high shear to help understand a variety of key quality attributes such as suspension stability, syringability and shear senitivity.