Here at the Centre we use a range of temperature-scanning rheological methods, with and without applied shearing and holding periods, to gain an understanding of a material’s thermorheological behaviour. While solutions will typically only display a simple viscosity-temperature relationship, complex materials containing fats and waxes can reveal intricate, multi-component melting or crystallization “signatures” as temperature is swept. The melting and cooling profiles, including changes in rigidity and viscosity, are of interest, along with the final physical properties of a product, both immediately following and some time after cooling. Product developers can use this information for predicting performance and storage behaviour and for second-sourcing ingredients and excipients. Process designers can use thermorheology data for scale-up, intermediate bulk storage and filling decisions.

Small amplitude oscillatory shear

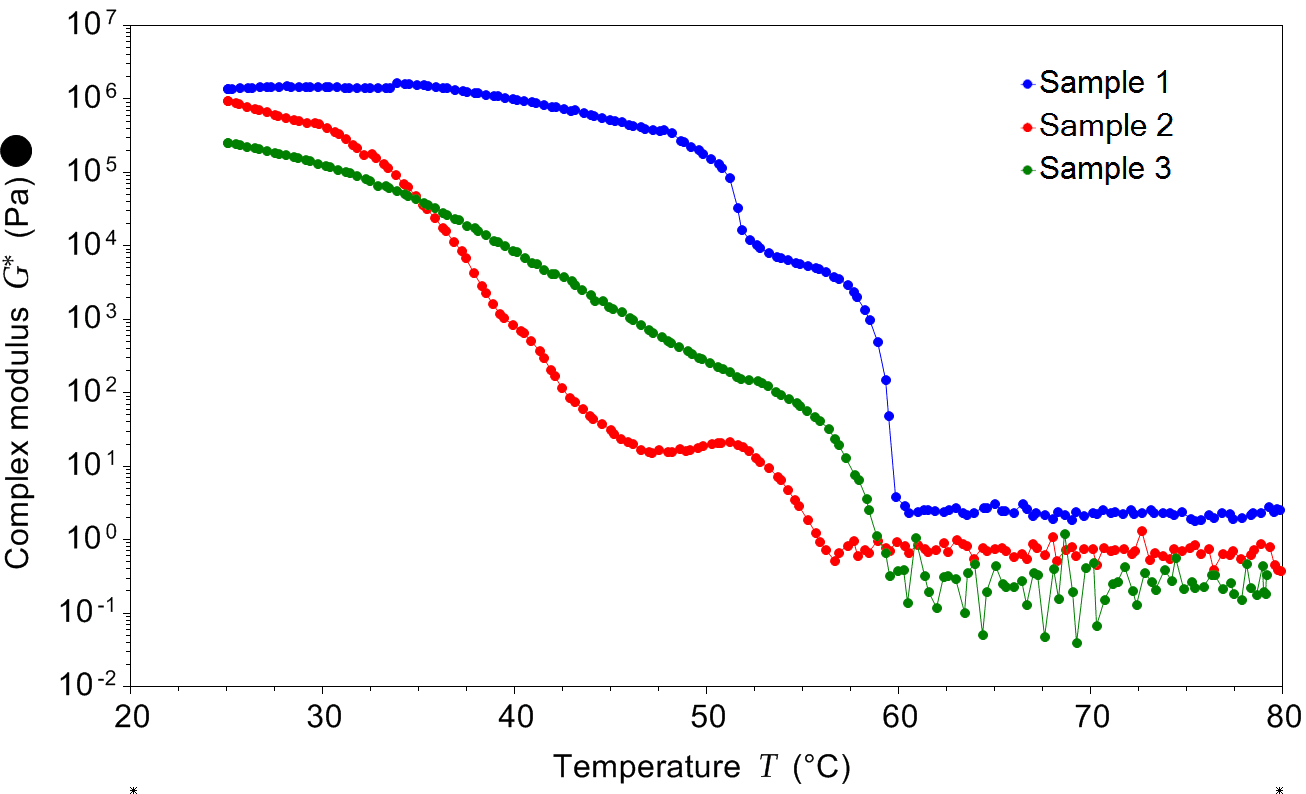

Oscillatory testing entails applying very small oscillating shear to a sample and measuring both it’s resistance to deformation and its viscoelastic response. The beauty of such “small-amplitude oscillatory shear”, or SAOS testing, is that the imposed deformations are generally so small that the testing itself does not affect the outcome. The plot opposite shows a typical output from oscillatory temperature sweeps performed on three petrolatum-based topical formulations.

“Thermorheological equivalence” testing for topical pharmaceuticals

Oscillatory temperature sweep tests, in combination with additional rheological profiling methods, can demonstrate the equivalence, or otherwise, of petrolatum and petrolatum-based products.

Petrolatum is a commonly-used excipient for pharmaceutical ointments and creams as a vehicle for an active ingredient or as an emollient, texturant or stabiliser. One of the challenges facing pharmaceutical developers is the uniqueness of petrolatum to a given feedstock, the complex mixture of solid waxes and liquid mineral oil resulting in a complex fingerprint of physical properties that can prove difficult to match. This can present challenges for companies formulating with the product. For example, if a petrolatum manufacturer’s feedstock is drying up their customer is left in a difficult situation needing to source an alternative supply that matches the petrolatum with which their formulation gained it’s necessary regulatory approvals. Another challenge is faced by manufacturers of generic topical formulations who are required to demonstrate equivalence to the original innovator’s product. If the reference product has a petrolatum base it will also possess a thermorheological fingerprint that, if matched, can help a generic formulator achieve, and demonstrate, a closer match.

excipient for pharmaceutical ointments and creams as a vehicle for an active ingredient or as an emollient, texturant or stabiliser. One of the challenges facing pharmaceutical developers is the uniqueness of petrolatum to a given feedstock, the complex mixture of solid waxes and liquid mineral oil resulting in a complex fingerprint of physical properties that can prove difficult to match. This can present challenges for companies formulating with the product. For example, if a petrolatum manufacturer’s feedstock is drying up their customer is left in a difficult situation needing to source an alternative supply that matches the petrolatum with which their formulation gained it’s necessary regulatory approvals. Another challenge is faced by manufacturers of generic topical formulations who are required to demonstrate equivalence to the original innovator’s product. If the reference product has a petrolatum base it will also possess a thermorheological fingerprint that, if matched, can help a generic formulator achieve, and demonstrate, a closer match.