Contact us for spreadability measurement prices

The Centre for Industrial Rheology performs physical testing of topical creams, ointments and lotions for assessing and demonstrating spreadability equivalence of generic and innovator’s pharmaceuticals.

Regulatory bodies, such as the FDA, are increasingly asking for characterisation of rheological properties such as shear stress/shear rate relationships, yield stress and viscoelastic moduli such as storage, loss and complex modulus to support Q3 structural equivalence claims.

Our service comprises:

- Comparative testing of

- Generic development formulations,

- The target reference listed drug

- If necessary, additional similar products to add context to the generic/RLD results.

- We provide a report with numerical and graphical results, explanatory notes and observations

- We then provide ongoing support with any relevant questions or concerns that may arise throughout the process

Spreadability: Viscosity, Structure and Viscoelasticity

Spreadability of gels, creams, ointments and lotions is the net result of a combination of rheological contributions, of which viscosity is just one. In addition, structural and viscoelastic characteristics that describe the rigidity, strength and relative contributions of elastic and viscous behaviour play a major role in imparting spreading properties. By way of an example below is simple rheological comparison performed on two topical pharmaceutical creams, one the original reference listed drug and the other a low-cost generic alternative. In the study both the flow (i.e. viscosity) and structural (rigidity and strength) behaviours are compared.

Viscosity measurements and the high shear rates of application

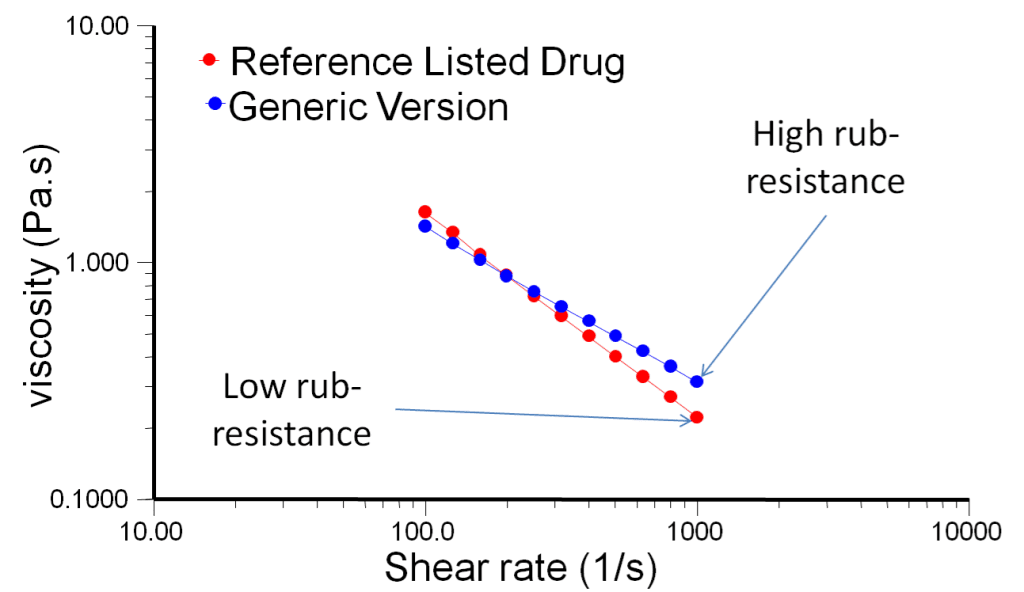

Topical creams are non-Newtonian, shear-thinning, materials, meaning their viscosity is high at low shear rates and low at high ones. For this reason it is essential that any viscosity measurements are performed at shear rates that are representative of the situation we are trying to simulate. In the case of spreadability predictions for topical products, application shear rates tend to be in the upper hundreds to lower thousands of reciprocal seconds.

This range is not achievable on a simple spindle viscometer but with a high-performance rheometer viscosity / shear rate profiles such as that shown below can be performed:

The results clearly show a divergence between the generic and the RLD at higher shear rates, with the former about 40% higher than the latter. In other words, the generic requires 40% more stress than the latter to rub apply.

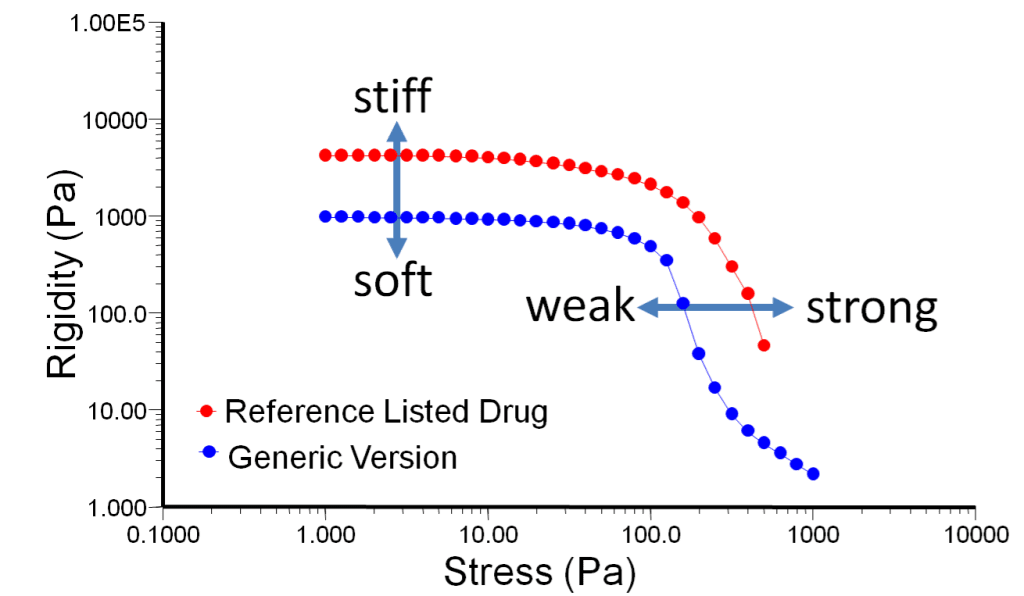

Structural comparisons

Critical, and often overlooked, characteristics for topical products are the rigidity and yield stress (gel strength) of the material in its semi-solid condition, prior to the application of high shear spreading stresses. The way to measure these properties is to perform gentle, small-deformation oscillation testing such as the oscillation stress sweep performed below:

Interestingly, despite the RLD’s lower high-shear viscosity, it has a stiffer (high rigidity) and stronger (high yield stress) structure than the generic version. The higher yield stress will manifest as the need for a greater force to be applied to squeeze the product from the tube and will be possibly easier to handle prior to application on the skin.

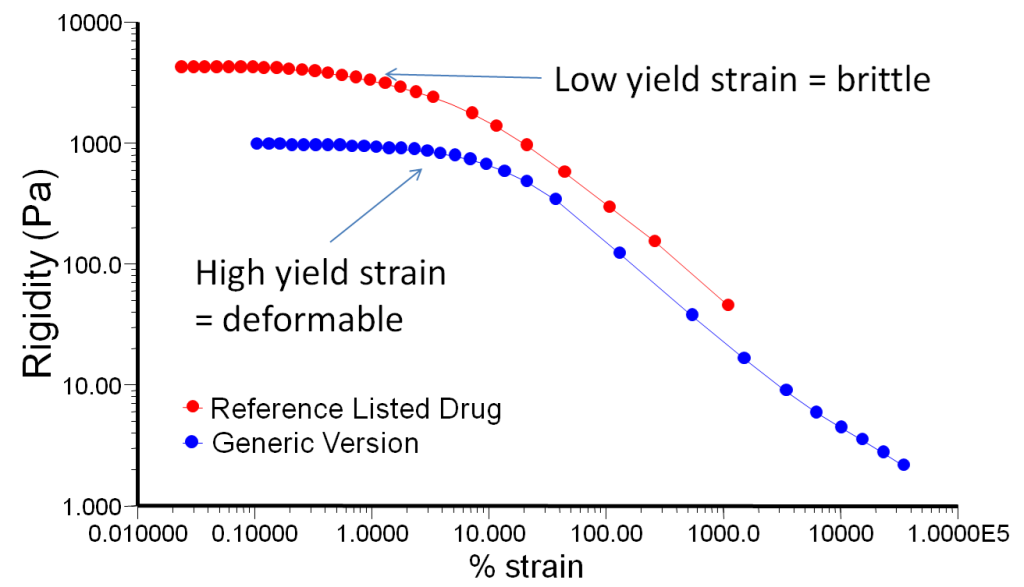

Finally, yield strain, the degree of deformation at which the sample starts to break, contributes to appearance and sensory characteristics. The lower yield strain of the RLD manifests as a brittle “cheesy” semi-solid nature rather than the “creamier” appearance and handling of the generic version.

Let us profile your topical products

We have a variety of searching test methods that can provide you with an understanding of spreading and application properties that are out of reach of simple viscosity testing methods. If you would like us to perform a profiling on your products – or those of your competitors – please don’t hesitate to get in touch to discuss your needs or obtain a quotation.

Contact us now to arrange a discussion about your needs