Tribo-rheological Profiling for Emollients

The sensory qualities of topical pharmaceuticals is rapidly becoming recognised as one of the drivers of patient compliance among sufferers of eczema, psoriasis, ichthyosis and other dermatological conditions where “complete emollient therapy” treatments are the frontline attack. Sensory qualities of spreadability and after-feel are a result of a combination of physical properties. The profiling techniques of rheology (deformation and flow) and tribology (friction and lubrication) are becoming increasingly established in the cosmetics world as essential measurements for formulators in need of objective quantification of these properties. Likewise an opportunity awaits the savvy formulator of topical pharmaceuticals to adopt these techniques for the benchmarking of marketed products and rapid screening of formulation iterations.

If you would like to discuss setting up your own investigation or how rheology can help you formulate for patient compliance, get in touch.

The cosmetic formulator is familiar with the terms pick-up, application and rub-out to describe the three stages of use of a skincare product.

- Pick-up: Relates to the initial handling, pumping, scooping and “carry-over”

- Application: Relates to the initial application on the skin and spreading of product

- Rub-out: Refers to the later stages of application and after-feel.

To obtain a comprehensive characterisation of the physical properties that contribute to these attributes it is necessary to quantify structure, flow and lubrication.

-

Structure

Emollient creams can be described as structured liquids; when under low stress conditions they behave as soft solids, only yielding to flowable liquids on the application of sufficient stress. Just like any solid these can be described by rigidity and strength. We call these properties modulus and yield stress.

-

Flow

When sufficient stress is applied to the soft solid mass of an emollient, such as throughout spreading, their structure breaks down and they flow like liquids. The resistance to flow is described by their viscosity.

-

Lubrication

In the later stages of application there is a significant interaction between the “asperities”, the peaks and troughs, of the spreading hand and the target skin surface. The ease with which this proceeds is highly dependent upon the lubricity of the product, a quality quantified by coefficient of friction.

We profiled three popular topical emollients and identified significant differences in their triborheological properties.

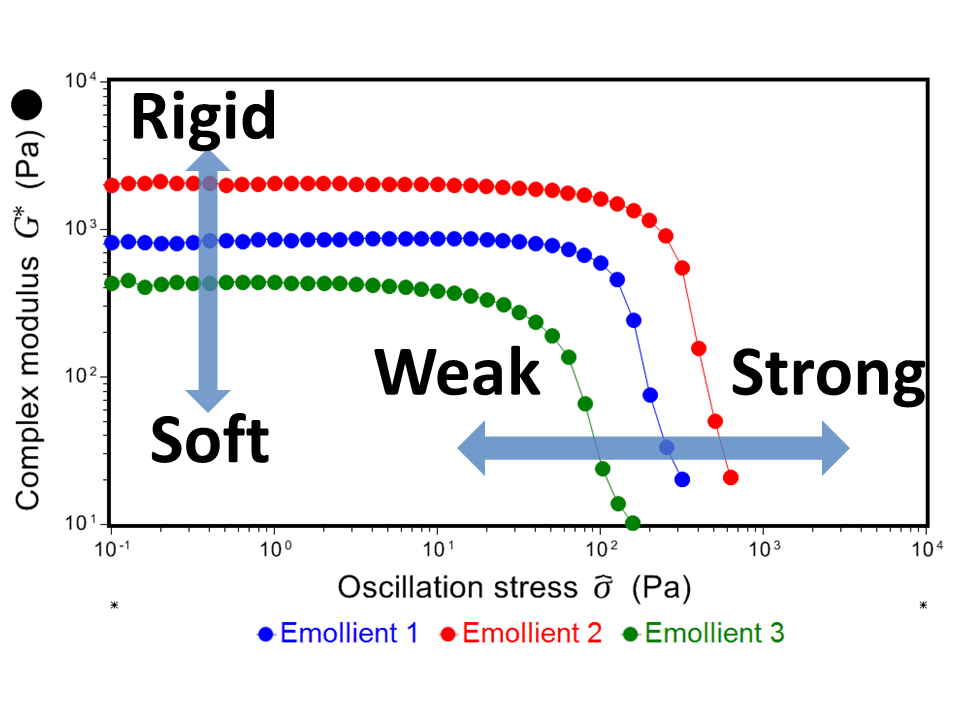

Structure profiling for yield stress and modulus

Oscillatory stress sweeping methods were used to quantify modulus and yield stress. In this test the sample is subjected to incrementing oscillatory stresses until an obvious yielding occurs in the sample’s structure.

The results clearly differentiate the products in both rigidity and strength, with emollient 2 having a complex modulus plateau of ~20,00 Pa being four times as rigid as emollient 3 with a complex modulus plateau of ~440 Pa. Emollient 3 has a weaker structure which yields at a force of ~70 Pa with emollient 2 being 4 times ‘stronger’ yielding at ~280 Pa.

These test results agree with the observed greater “body” and more “buttery” appearance of emollient 2 compared to the other formulations.

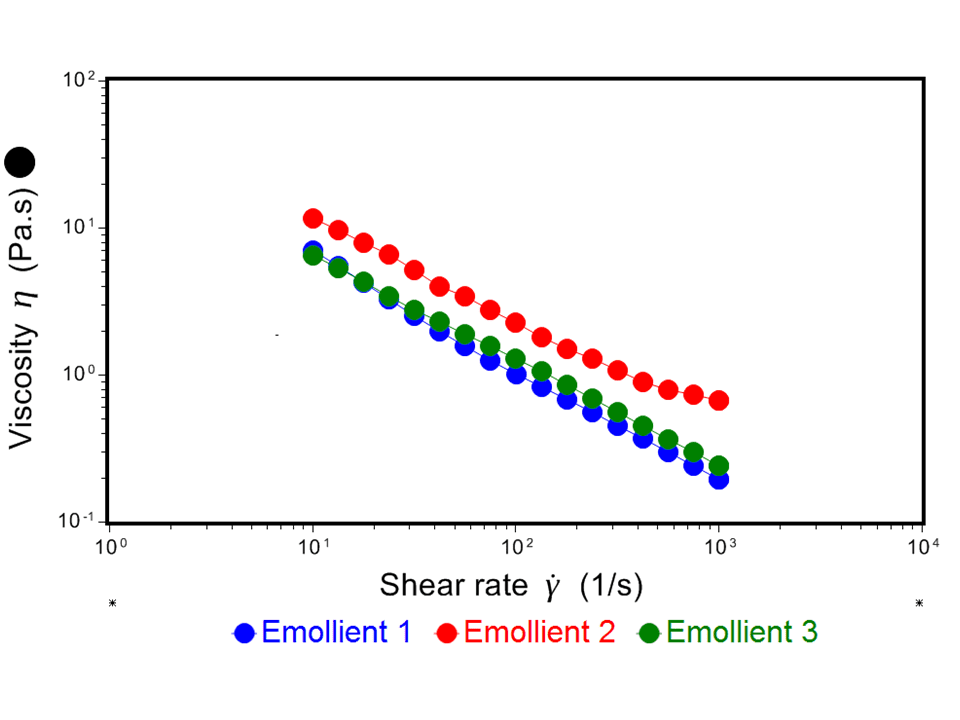

Viscosity measurements

Emulsions demonstrate non-Newtonian flow behaviour. This means that their viscosity is not a single value but is dependent upon the shear stress or shear rate that is being applied at the time of measurement. A shear rate sweep method was employed to quantify viscosity of the three creams:

The test results clearly show that emollient 2 has a higher viscosity than the other two products. It is particularly evident that the viscosities of emollients 1 and 3, compared to 2, diverge as shear rate is increased. This is significant as the shear rates imposed during application onto the skin are estimated to be in the upper end of the shear rate range.

The drag force during application will be a function of the shear stress required to maintain shearing at high shear rates. Emollient 2 requires approximately five times the shear stress to achieve shear rates of 1000s-1. This is expected to contribute to the increased drag observed in this product on application.

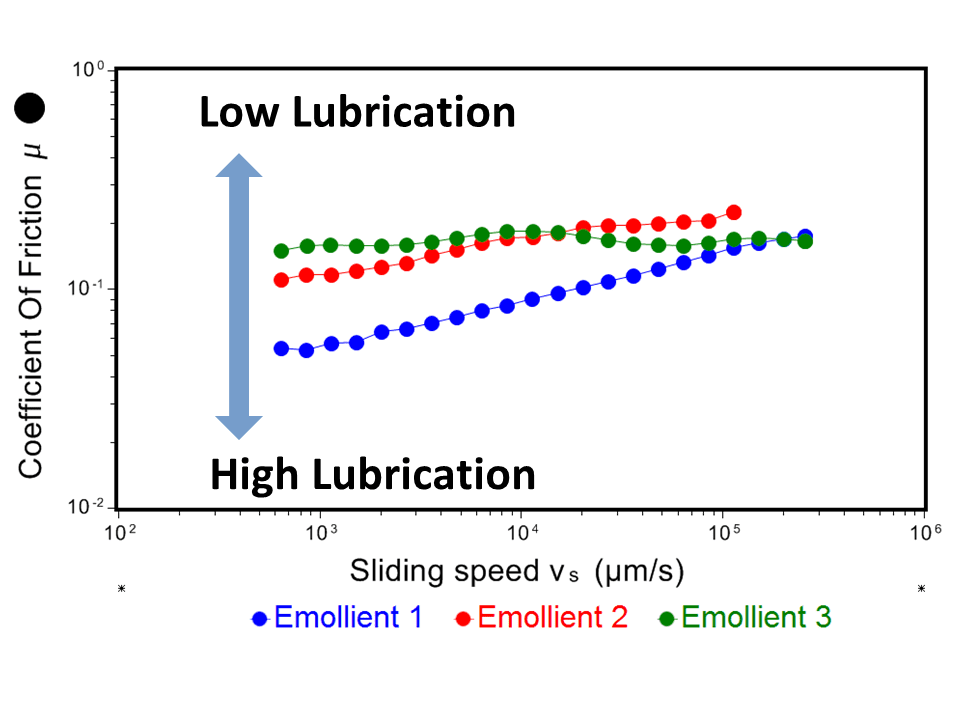

Tribological profiling for lubricity comparisons

Using a custom-built tribology assembly, coefficient of friction was measured under a defined load force across a range of sliding speeds to produce the plots below:

Emollient 1 is clearly differentiated from the other two creams, with a significantly lower coefficient of friction across the sliding speed range. This would be expected to contribute to a more lubricious after-feel in that product.

Summary:

-

Optimising sensory attributes offers the pharmaceutical formulator an opportunity for improved patient compliance in emollient products.

-

Sensory attributes are the result of physical properties including rheological and tribological characteristics.

-

Structure, flow and lubricity measurement methods are available for the formulator looking to develop superior dermatological formulations.

If our article touched upon any challenges you’ve come across, let us know how we can help.