We can provide rheological benchmarking of recycled polymers to help identify minimum requirements for virgin plastic additions. Accurately and quickly quantify the share of virgin and recycled polymer required to achieve a desired quality of product for application. Our lab can also identify to what extent your feedstock composition or processing affects the final physical properties of your recycled plastic, and help investigate thermal driven chain scission or ‘random’ polymerisation.

The Centre for Industrial Rheology provides testing, training and consulting services in the fields of rheology, dynamic mechanical analysis, tribology, interfacial science and powder flow analysis for a myriad of industries.

Contact us to discuss rheological screening of your recycled polymers.

As the pressure increases on businesses to improve their environmental credentials, there is a rising need to develop plastics which are easy to reuse and recycle. Thermoplastics are generally considered the most appropriate candidate for re-use however, plastic packaging is often used in tandem with other materials such as inks, pigments, paper, metals, adhesives and indeed other plastics that make recovery and use of recycled polymers highly challenging.

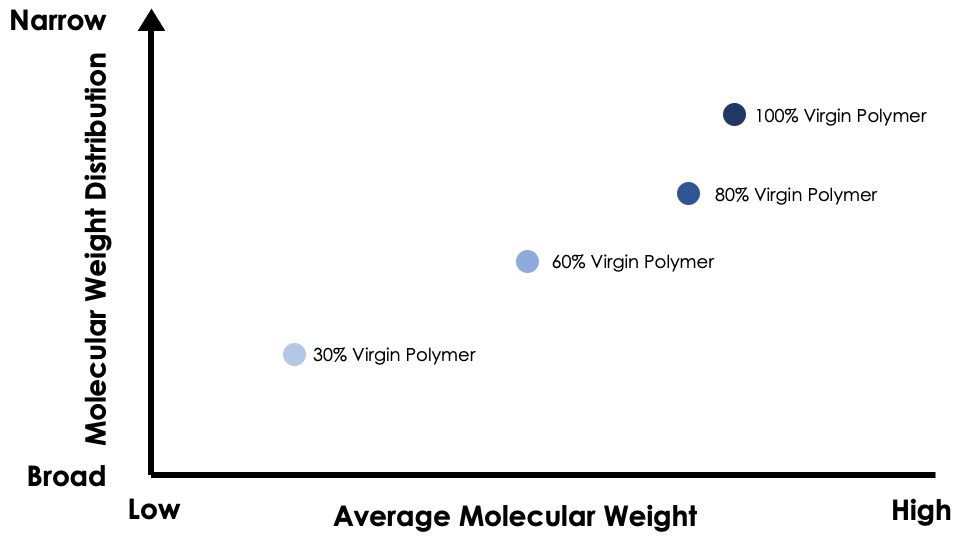

At scale it can be very difficult to completely eliminate these impurities from the recycled plastic, and the processing of the plastic itself may affect its overall properties making it unsuitable for its first intended use. By rapidly quantifying how different your recycled feedstock is from your virgin polymer, it is possible to specify a quality protocol that tells you how much virgin polymer to add to achieve minimum quality requirements.

We provide characterisation of polymers under a variety of settings similar to process conditions, to help businesses understand how their feedstock composition and processing can affect the final physical properties of the recycled polymer.

Oscillatory Rheology for Recycled Polymers

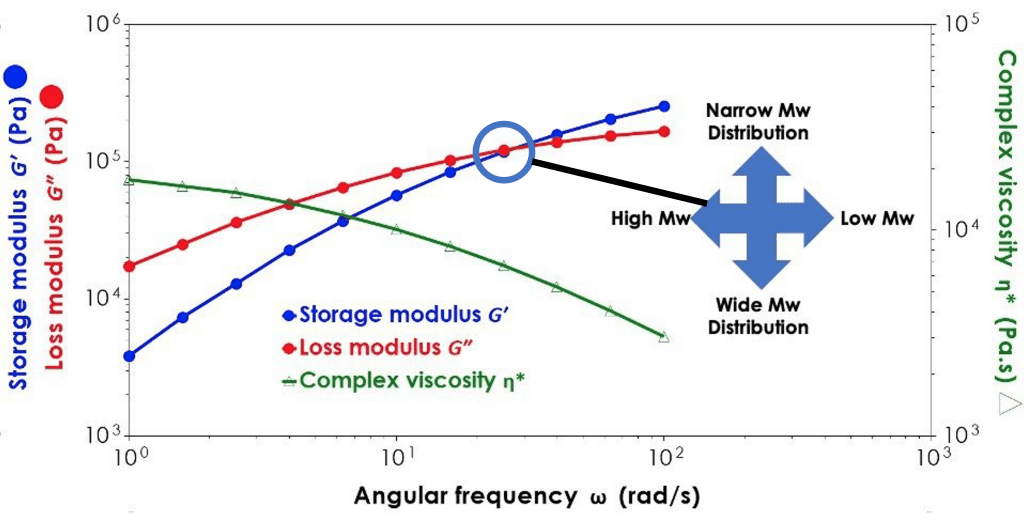

Small amplitude oscillatory frequency sweeps are a highly sensitive rheological method for characterising viscoelastic behaviour of polymers and can provide a lot of useful information about handling properties, and microstructural properties such as average molecular weight distribution. The sample is subjected to small sinusoidal oscillations and the material response is monitored.

From this test the following metrics can be obtained:

| Complex Modulus | G* | A measure of the overall rigidity of the sample |

| Elastic Modulus | G’ | A measure of the elastic response of the material |

| Viscous Modulus | G” | A measure of the viscous response of the sample |

| Complex Viscosity | η* | A calculated value for viscosity using the Cox-Merz transformation |

| Zero Shear Viscosity | η0 | A plateau value reached for viscosity under close to zero-shear conditions |

The crossover point of G’ and G” can be a useful indicator of how molecular weight average and molecular weight distribution have changed before and after processing of your polymer.

A crossover point at a lower frequency than its benchmark indicates the polymer has a higher molecular weight, whereas a crossover at a higher frequency indicates a lower molecular weight.

The maximum in G’ is also a good indicator of the broadness of molecular weight distribution, with high values indicating a narrower distribution. A lower G’ value indicates a broader distribution.

A high zero shear viscosity is indicative of a higher molecular weight average, so changes in zero shear viscosity to a polymer because of processing can tell you about chemical changes to the material that have affected its molecular weight. A polymer with a broad molecular weight distribution also has an earlier onset of non-Newtonian behaviour past the zero shear plateau.

If you have a variety of polymers which you are looking to benchmark and are simply trying to quantify differences in behaviour between your sample set, then please feel welcome to arrange a meeting with us. We’ll be happy to provide a video tour of the lab and discuss how we can help you better understand your recycled plastic.