We measure the tension and rheology (modulus and elasticity) of liquid/liquid and liquid/air interfaces for companies looking to create optimum foam formation or retention/stability behaviours. The Centre for Industrial Rheology performs several characterisations including dilatational interfacial measurements, shear interfacial measurements and dynamic interfacial analyses alongside other rheological analyses to help companies fully explore and exploit characterisation data for their applications.

We measure the tension and rheology (modulus and elasticity) of liquid/liquid and liquid/air interfaces for companies looking to create optimum foam formation or retention/stability behaviours. The Centre for Industrial Rheology performs several characterisations including dilatational interfacial measurements, shear interfacial measurements and dynamic interfacial analyses alongside other rheological analyses to help companies fully explore and exploit characterisation data for their applications.

Whether it’s the head on your beer, the cloud-like throne you build during your bubble bath, insulation in your home or lifesaving foam used in firefighting, the formation and stability of foams is of great interest to myriad industries and applications.

If you would like to open a discussion about interfacial rheology for foam stability, please feel welcome to contact us.

Foams can generally be thought of as pockets of gas trapped by a liquid or solid. For liquids, the stability of the interface is a key driver for the overall stability of the foam, and this is influenced by the viscosity, surface tension and drainage of the liquid or entrapping phase. Surfactants play a key role in helping to moderate the physical behaviour of the liquid-gas interface and being able to objectively quantify the degree to which surfactants can affect fluid-film behaviour is of key interest to multiple industries.

Foams can generally be thought of as pockets of gas trapped by a liquid or solid. For liquids, the stability of the interface is a key driver for the overall stability of the foam, and this is influenced by the viscosity, surface tension and drainage of the liquid or entrapping phase. Surfactants play a key role in helping to moderate the physical behaviour of the liquid-gas interface and being able to objectively quantify the degree to which surfactants can affect fluid-film behaviour is of key interest to multiple industries.

From Surface Tension to Dilatational Interfacial Rheology

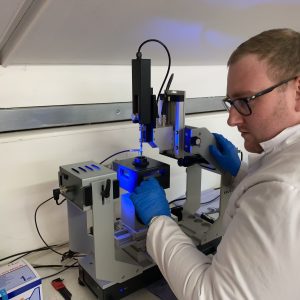

A common method for measuring the surface tension of a liquid is to suspend a droplet from the end of a needle and fit a curve to its silhouette. Gravity acting upon the droplet will pull it down into a pendant tear shape whereas surface tension will resist an increase in surface area and attempt to pull the droplet into a spherical shape.

Samples that are made up of significantly long chain molecules, or those that contain a significant concentration of surfactants do not immediately reach an equilibrium surface tension. The rate at which equilibrium is reached is influenced by the ability of the internal bulk material to replenish the surface of the droplet as its surface area increases and the configuration or alignment of molecules once they have reached the surface.

In a dilatational measurement, we oscillate the volume of the droplet and track the change in surface tension. A material displaying dominant elastic behaviour will change its surface tension in phase with the change in droplet volume, whereas a material with dominant viscous behaviour will display a delay or phase lag in surface tension as droplet volume changes.

Interfacial Shear Rheology

Interfacial Shear Rheology

In addition to studying interfacial rheology in dilation, we are also capable of characterising interfacial rheology in shear using our du Nuoy ring apparatus. The du Nuoy ring is a platinum-iridium ring that is lowered onto a liquid interface. The ring is assumed to be perfectly wetting, can apply shear deformations at the interface. In rotational shear mode, we apply a shear deformation to the interface and can quantify the interfacial shear viscosity of a liquid. In oscillatory shear mode, we can gently wobble the ring back and forth to probe elasticity of the interface and structure evolution properties.

Shear Rheology Measurements

The drainage of bulk material from an interface is heavily influenced by the viscosity of the material. Our high sensitivity rheometers are capable of measuring viscosity under a range of temperatures or shear conditions. A higher viscosity material will be more likely to resist drainage from the bulk of the film and can contribute to foam stability.