Viscosity and rheology play a crucial role in the performance of liquid and semi-solid household products such as detergents, glass cleaners or green/ environmentally friendly cleaning aids. From design and formulation to processing and quality assurance and all the way to end use and customer perception. Our rapid testing service, expert advice and practical training is all tailored to help you create the most efficient process and the highest quality products.

Please feel welcome to contact us in regards to characterising the physical properties of your household cleaning products.

Aiding in Formulation and New Product Development

Choosing from a range of solvents, surfactants, binders, esters and thickeners to achieve marketable properties such as ‘high concentration’, ‘environmentally friendly’ or ‘better cleaning’ can be a significant challenge for formulators and new product developers. Rheological data can provide key measurables and targets for formulation and reformulation, and quantitatively describes how changes in formulation affect your final product.

Enabling Processing and Quality Assurance

Different mixing, pumping and temperature regimes found in a laboratory setting compared to that of the factory floor can result in major differences in your final product versus your initial formulation. A high-performance rheometer can accurately match the temperature and shear conditions that your product will experience during manufacturing and help to underpin processing issues. Rheological values can also provide a quick and cost-effective measurement for quality assurance by allowing you to quickly compare key metrics to benchmark values.

Designing a Customer Experience

The experience of a household cleaning product has a marked psychological impact on its perceived performance. Understanding the chemical and physical characteristics that backup observable properties is key. Do you want your household cleaning product to seen as “thicker” for a more luxury feel? What feels luxurious in a dish soap may be detrimental to a glass cleaner. Do you want it to be more pourable? Your customer expects a totally different pour profile from their drain unblocker than they do from their laundry softener. How do you want the product to behave once it’s been sprayed? An air freshener should spray completely differently than a wood polish. By providing measurements like viscosity, shear thinning, yield stress and surface tension we help elucidate the physical properties that underpin observable traits, and help you design the optimal customer experience.

A Product Can Only Clean What It Can Touch

In many instances, rheology also plays a vital role in product performance. A cleaning product can only be effective over the area it covers. A toilet cleaner or descaler that drips and creates fingers instead of falling as a smooth film leaves large areas of the surface untouched and uncleaned. Viscosity, yield stress and surface tension can help us to understand the factors that lead to a smooth, unified wetting front versus dripping toilet fingers.

Similarly for a spray-on product, increasing area coverage is a great way to improve product performance. Atomisation of a product into liquid droplets requires a relatively high shear and understanding how a product behaves at those conditions as opposed to at rest is vital to understanding coverage. Does my product have the right viscosity to be sprayed? What size droplets does it form, and how much area do they cover? Does subjecting my product to such a high shear change how it behaves on the surface? These are all questions that can be explored by rheology with measurements such as viscosity, yield stress, surface tension, normal stress and thixotropy.

How Much of your Product is Actually Getting to Work?

Both in spray-on and squeeze-on products, getting the product to the surface is only half of the battle. Once deposited the active ingredients present in your drop or film are free to get to work on the substrate. There is a good chance however that the majority of your product isn’t even in contact with the surface it is trying to act upon. Managing drop size, or film thickness plays a role here, but do not provide the whole answer. Dynamic surface tension and oscillatory rheology measurements provide a key insight into the ability of active ingredients and cleaning agents to move from the bulk of the solution to where they are needed most.

Both in spray-on and squeeze-on products, getting the product to the surface is only half of the battle. Once deposited the active ingredients present in your drop or film are free to get to work on the substrate. There is a good chance however that the majority of your product isn’t even in contact with the surface it is trying to act upon. Managing drop size, or film thickness plays a role here, but do not provide the whole answer. Dynamic surface tension and oscillatory rheology measurements provide a key insight into the ability of active ingredients and cleaning agents to move from the bulk of the solution to where they are needed most.

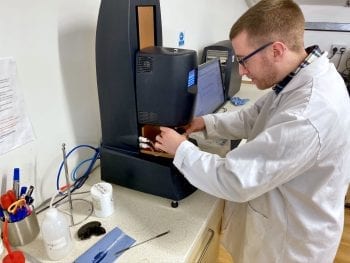

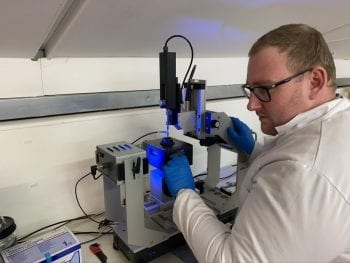

Sophisticated characterisation performed quickly, and made easy to understand

Sophisticated characterisation performed quickly, and made easy to understand

The Centre for Industrial Rheology features high-performance research rheometers and range of viscometers, drop shape analysis and texture analysis capabilities coupled with many years’ experience as an industry focused, specialist rheology lab. We help the world’s leading companies solve formulation, processing and quality problems.