Simple rheological testing can be a powerful tool to understand the reversible and irreversible changes that your cheese will go through when exposed to heat, and how those changes affect the cheese that reaches your mouth. Values like modulus (rigidity) and phase angle (elasticity) can be invaluable for formulation, R&D and process development to target specific properties and melting profiles.

Simple rheological testing can be a powerful tool to understand the reversible and irreversible changes that your cheese will go through when exposed to heat, and how those changes affect the cheese that reaches your mouth. Values like modulus (rigidity) and phase angle (elasticity) can be invaluable for formulation, R&D and process development to target specific properties and melting profiles.

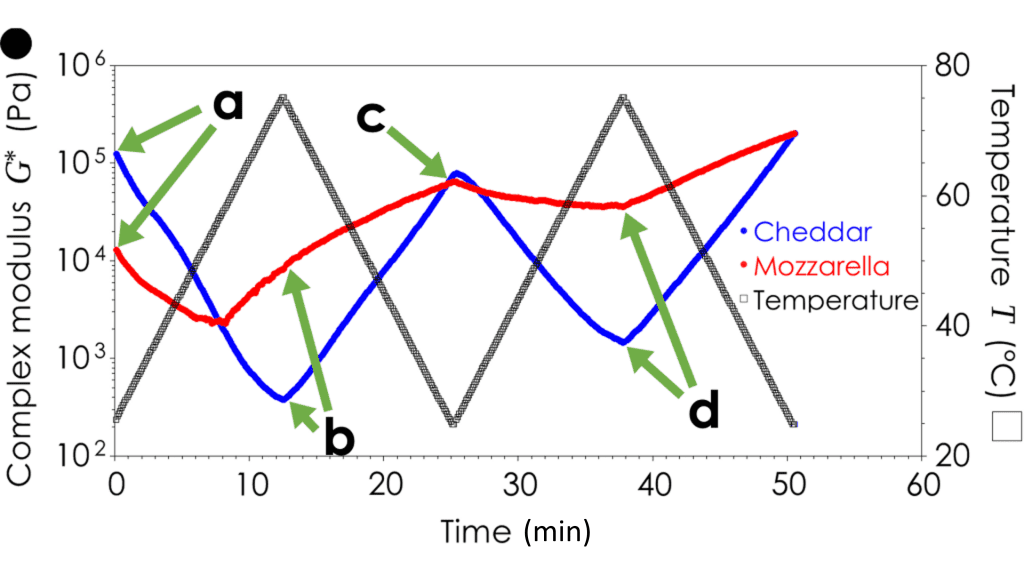

- Complex Modulus – Indicates the overall “rigidity”, or resistance to deformation, of the sample

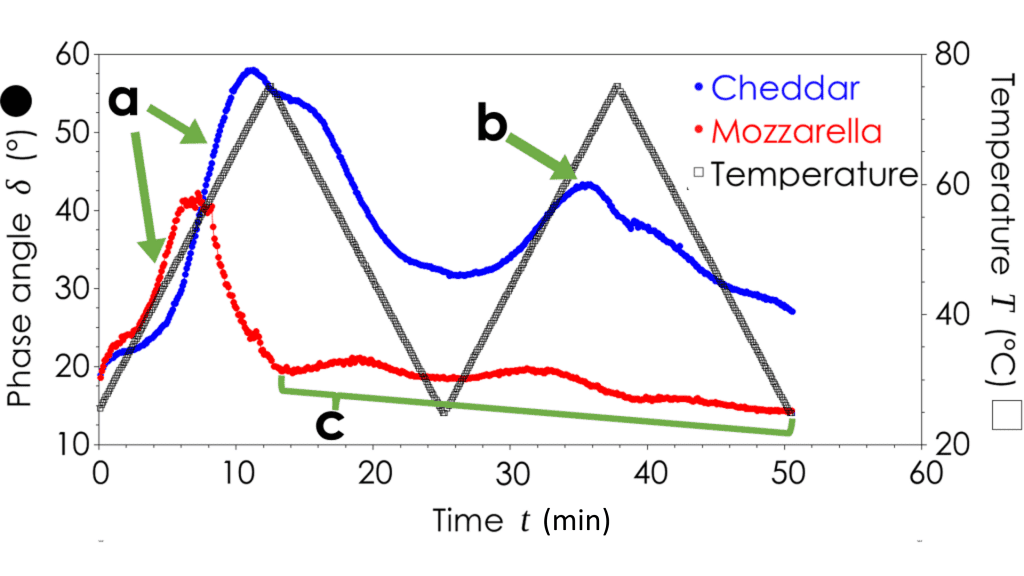

- Phase Angle – A measurement from 0° to 90° with 90° indicating a perfect liquid and 0° indicating a perfect solid with a range of properties in between.

If you would like to learn more about how to characterise the meltability of your cheese, and other important physical characteristics, please feel welcome to arrange a discussion with us.

As a cheese is heated it goes through a range of chemical changes. Proteins are broken down, moisture is expelled, and solid fat globules become liquified. Some of these changes are reversible, some are not, and all will have an impact in the product which reaches your customer. By utilizing some simple rheological measurements, generated while cycling the temperature of the product, we are able to create a profile of the melt rheology of your cheese. This data can be used to mimic melt-properties when changing ingredients (E.G creating a low fat version of a product), benchmark against a competitor’s product or design the perfect cooking process for your cheese.

As a cheese is heated it goes through a range of chemical changes. Proteins are broken down, moisture is expelled, and solid fat globules become liquified. Some of these changes are reversible, some are not, and all will have an impact in the product which reaches your customer. By utilizing some simple rheological measurements, generated while cycling the temperature of the product, we are able to create a profile of the melt rheology of your cheese. This data can be used to mimic melt-properties when changing ingredients (E.G creating a low fat version of a product), benchmark against a competitor’s product or design the perfect cooking process for your cheese.

Generating Melt Profiles with Rheology

How fast does your product melt? What’s the best temperature to melt it at? How long do you need to heat it? Will it re-melt once cooled? All of these questions can be explored with oscillatory rheology.

An oscillatory test wobbles the sample back and forth applying fairly gentle stresses. It then measures how much the sample bounces back versus how much it has permanently changed. With this test, we can obtain information about the structure of the sample. By cycling temperature while we apply these gentle stresses, we can understand how the structure of the sample is reacting to the temperature change, and what changes are reversible once the temperature is brought back down to room temperature. Oscillatory rheology tells us about the overall rigidity of the sample with complex modulus, and the structured nature of the sample with phase angle.

What Does an Oscillatory Rheology Test Tell Me?

As the temperature of a cheese rises, the protein matrix breaks down and the fat liquefies and moisture is lost, and all of this changes the structure of the cheese and thus its physical properties. Oscillatory rheology can tell you how fast that structure is broken down, at what temperature that process happens, and to what extent that breakdown is recoverable.

As the temperature of a cheese rises, the protein matrix breaks down and the fat liquefies and moisture is lost, and all of this changes the structure of the cheese and thus its physical properties. Oscillatory rheology can tell you how fast that structure is broken down, at what temperature that process happens, and to what extent that breakdown is recoverable.

One oscillatory test yields a few different measurements that can all play a key part in understanding how your cheese melts.

Precise Control and Rapid Testing – The Advantages of Rheology

With rheology, we are able to precisely control the conditions of your sample. Is your cheese thrown into a pizza oven at 150 degrees for 130 seconds, removed to room temperature, and then thrown into a 7 degree fridge before being reheated to 100 degrees in a pan? We can follow the temperatures and timing of that process exactly, and measure the properties of the cheese the whole way through. We can perform this testing on small sample sizes, often within days of receiving a sample, and we can back that testing up with support and advice from rheology experts to help you get the most out of the data.