The interfacial rheology of plant-based proteins has steadily grown in interest due to the need in developing sustainable plant-based sources of emulsifiers and stabilisers. The interfacial tension and interfacial rheology of surfactants are of great interest to formulators due to their influence in creating and stabilising interfaces such as in emulsions or even foams. We provide a comprehensive characterisation service covering both interfacial and bulk properties of plant-based proteins and back up all our reports with ongoing technical support.

Contact us to discuss how we can help.

As societal preferences change towards sustainable animal-free sources of food, food manufacturers are under pressure to replace animal-sourced ingredients with plant-based substitutes. The challenge lies in finding, identifying, or trying to mimic the highly specific properties that animal proteins possess that are lacking in plant-based proteins.Proteins can be highly sensitive to changes in pH and salt, changing the way they fold and interact with other proteins while suspended in solution or indeed when at an interface. This ability to change their ‘conformation’ or folding state based on environmental or spatial influences and indeed their interaction with other proteins to form complexes or aggregates, is in part why some animal proteins are excellent at their jobs, and why they can be difficult to replace with plant-based biosimilars.

Interfacial Dilatational Rheology

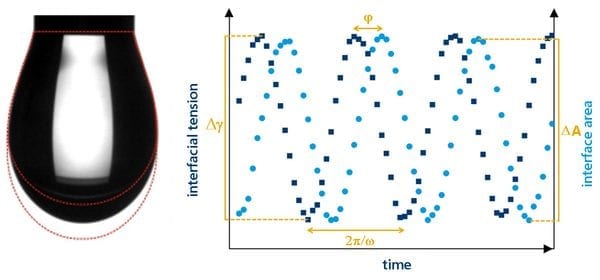

Dilatational measurements involve fitting a curve to the silhouette of a droplet, calculating the surface tension of a droplet suspended from a needle in air, water, or a liquid of interest. Surface tension acts to pull the droplet into a more spherical shape whereas gravity acts to deform the droplet into a tear shape. A droplet in a spherical shape will therefore have a higher surface tension than a droplet in a tear or pendant shape.

In oscillatory interfacial dilatational rheology, the volume of the droplet oscillates across a range of frequencies and change in surface tension over time is measured. An oscillatory dilatational test specifically looks at the ease or speed at which a surface-active material, like a protein emulsifier, can migrate to and from the surface and bulk.

If the change in surface tension and change in volume acts instantaneously or ‘in-phase the interface is said to be behaving elastically. If there is a delay or phase lag, the interface is said to be behaving viscously. If it is more difficult for a surfactant to reach an interface, the surfactant will be less effective at stabilising the interface.

Interfacial Shear Rheology

In an interfacial shear test, a Du Noüy ring is brought into contact with an interface, then the interface can be sheared to measure the interfacial viscosity – a measure of the resistance to shear of the interface. Alternatively, the ring can be wobbled at the interface to obtain the viscoelastic shear moduli. Similar to the dilatational test, the interface is subjected to deformations at a set frequency and either the strain or stress encountered is measured.

If you are looking to identify key interfacial behaviours of your plant-based protein, that help understand emulsion or foam creation and stability, then we have a variety of materials characterisation techniques to help you uncover these insights. We can perform benchmarking studies to help map competitors against your formulations, investigate the impact of pH, salts or oil/water combinations, and even temperature-dependent effects. Contact a member of our sales team to arrange a tour of the lab and discuss how we can help.