Rheology testing reveals a world of difference between condiments of similar viscosity values

This investigation demonstrates how viscosity measurement alone is far from adequate for characterizing the consumer-perceived attributes of three popular condiments: Heinz Tomato Ketchup, Daddie’s Brown Sauce (a popular British brand) and French’s Burger Mustard – all of which display subtly differing textures and handling characteristics. Research rheometers offer a powerful weapon in the arsenal of the product developer looking to contrast and quantify these subtleties.

This investigation demonstrates how viscosity measurement alone is far from adequate for characterizing the consumer-perceived attributes of three popular condiments: Heinz Tomato Ketchup, Daddie’s Brown Sauce (a popular British brand) and French’s Burger Mustard – all of which display subtly differing textures and handling characteristics. Research rheometers offer a powerful weapon in the arsenal of the product developer looking to contrast and quantify these subtleties.

Non-Newtonian Flow

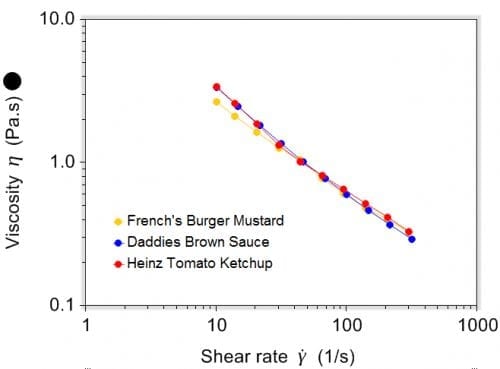

The graphic below shows the result of viscosity/shear rate profiles performed on the samples. All three products demonstrate significant non-Newtonian shear-thinning across the range tested, with viscosity at high shear around a tenth of the value obtained at low shear.

Such non-Newtonian shear thinning is an obviously desirable attribute that allows a condiment to be delivered easily from a bottle (low viscosity at “squeezing” shear rates) and yet retain a rich texture on the plate (high viscosity at low shear rates). Contrast this behaviour to the Newtonian flow of honey which necessitates a hard squeeze on delivery yet flows under its own weight.

Whilst measuring viscosity across a range of shear conditions clearly delivers a significant advantage over simple single-speed viscosity tests this is evidently insufficient to differentiate the products tested, as all three products show very similar flow curves.

Oscillatory shear testing

Small amplitude oscillatory shear (SAOS) is the umbrella term that describes a range of rheological testing methods that entail the application of small, oscillatory stresses or strains to a sample whilst its resulting elastic (solid-like), viscous (liquid-like) or combined viscoelastic response is observed. Applied stress, strain, oscillation frequency or temperature can be changed in a continuous or step-wise manner to explore a material’s behaviour under a range of circumstances.

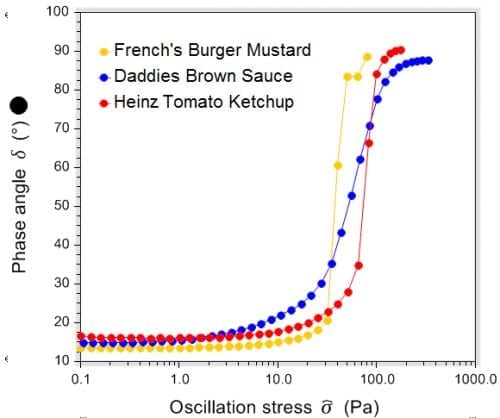

Below is the result of performing an oscillation stress sweep on the three condiment samples. In this test the sample is subjected to incrementing oscillatory stresses. The graphic shows phase angle plotted against stress, phase angle is a measure of the relative dominance of elastic or viscous response of the sample and ranges from 0° for an ideal elastic material (i.e. a perfect solid) to 90° for an ideal viscous material (a perfect liquid).

All three materials show similar soft-solid behaviour at the lowest stresses, yielding to liquid flow as the incrementing stress disrupts the thickening structures present, however the Daddies Sauce shows a deviation from the plateau at a noticeably-lower stress than the other samples. The lower yield stress of the Daddies Sauce manifests itself as easier “pourability” and a noticeably-more mobile product.

Rheology Contributions to Stiff, Soft, Short and Long Textures

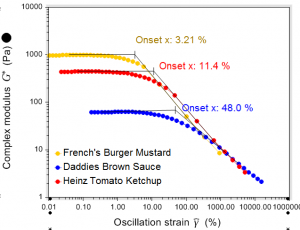

It is also instructive to plot complex modulus, a measure of the rigidity of soft-solid structure, as a function of strain, the deformation in the sample, as in the plot below:

Two useful metrics are obtained from this plot: the plateau value of complex modulus demonstrates that the mustard and ketchup are both relatively stiff whereas the Daddies Sauce is at least ten times softer. Secondly, this information, in addition to the relative yield strains (i.e. breaking deformations) quantified by extrapolated onsets, contrasts the short, “brittle” structure of the mustard with the longer, more deformable texture of the Daddies Sauce.

To summarise, quantification of the key rheological properties of food sauces, including yield stress, yield strain and complex modulus, can illuminate the smart product developer to the nuances of texture and handling that differentiate winning products in a competitive marketplace.

If you would like to learn how these metrics and others can help you formulate your products please contact us.