The syringeability of dermal fillers is a key intuitive measurement often at the forefront of a clinician’s mind. The ability to deposit precise amounts of product, in a way that is comfortable to the patient, depends on inherent physical handling behaviours of the product and design of the syringe itself. Profiling the resistance encountered as a plunger tip travels down the barrel in a quantitative manner, enables unambiguous comparisons of the syringeability of a dermal filler. We offer simple, rapid characterisation services to help benchmark dermal fillers on their syringeability and can help you interpret data to identify opportunities for improvement.

The syringeability of dermal fillers is a key intuitive measurement often at the forefront of a clinician’s mind. The ability to deposit precise amounts of product, in a way that is comfortable to the patient, depends on inherent physical handling behaviours of the product and design of the syringe itself. Profiling the resistance encountered as a plunger tip travels down the barrel in a quantitative manner, enables unambiguous comparisons of the syringeability of a dermal filler. We offer simple, rapid characterisation services to help benchmark dermal fillers on their syringeability and can help you interpret data to identify opportunities for improvement.Contact us to discuss benchmarking dermal fillers for their syringeability

When designing a dermal filler, formulators consider a huge range of factors to ensure the filler looks and works great once deposited. It can be easy to forget how material characteristics that give rise to those post deposition properties affect the filler pre-deposition. Yet, every time a clinician uses the product, its ease of use is immediately noticed as a perceived indicator of quality. These subtle differences can be highly influential in affecting their purchase preferences, or product recommendations.

When designing a dermal filler, formulators consider a huge range of factors to ensure the filler looks and works great once deposited. It can be easy to forget how material characteristics that give rise to those post deposition properties affect the filler pre-deposition. Yet, every time a clinician uses the product, its ease of use is immediately noticed as a perceived indicator of quality. These subtle differences can be highly influential in affecting their purchase preferences, or product recommendations.

At best, good syringability can aid with accuracy and reduce user fatigue. At worst, bad syringeability can lead to horror stories of needles being ejected off the end of syringes mid use! If two products both work equally well once deposited, it goes without saying that the most successful will be the one that provides the best user experience.

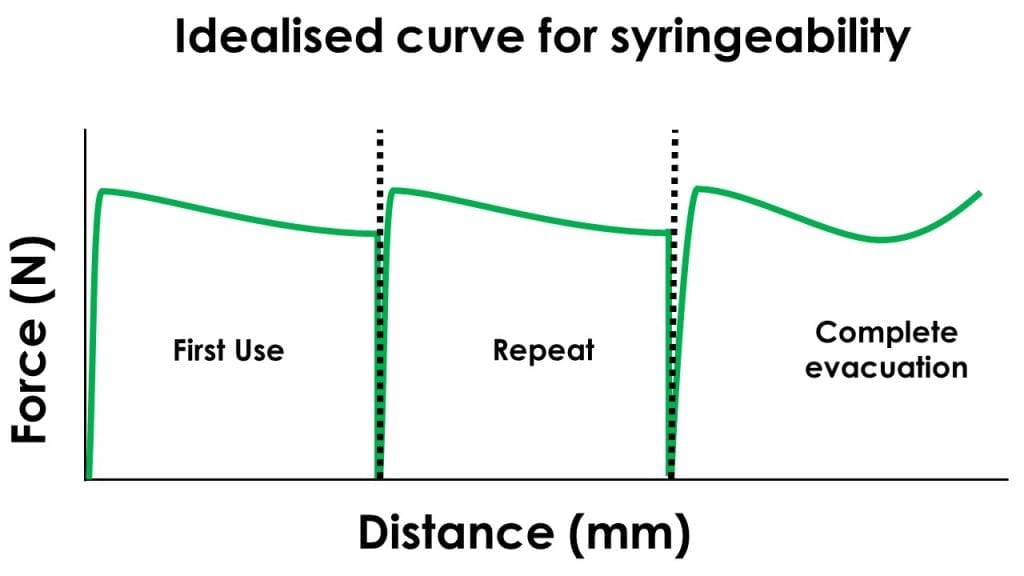

Typical plot for syringeability of dermal fillers

Our equipment can measure the resistance encountered as a plunger is depressed at a set speed. The source of resistance can be broken down into three main causes:

- Static limiting friction describes the friction between two static objects, for example between the plunger and the syringe chamber at the very start of deposition.

- Dynamic friction (also known and kinetic friction or sliding friction) is the friction between objects in motion.

- Compression of the dermal filler as it is squeezed between the plunger and the end of the syringe. This appears as a second peak at the end of the test known as the end constraint.

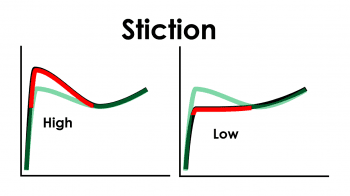

Stick Slip: Getting the plunger moving

The initial force required to get a syringe plunger moving is called stiction. Stiction, is the first noticeable challenge to ease of administration.

The initial force required to get a syringe plunger moving is called stiction. Stiction, is the first noticeable challenge to ease of administration.

A small amount of stiction is unavoidable due to the combination of dynamic friction and static friction. Controlling stiction, is vital to a smooth, accurate and, clinician friendly dermal filler. A small amount of expected stiction can aid in accuracy. Too much stiction can cause accidents through over-deposition – imagine the stress building up behind the plunger tip to overcome stiction, then ejecting the dermal filler in an uncontrolled manner. At best this wastes product but at worst can cause harm or deformity to patients.

The stop-start nature in which dermal fillers are often used, creates another challenge with stiction. Clinicians will typically insert a needle into multiple targeted areas, depositing small amounts of dermal filler where needed. Stiction plays a role each time the plunger tip moves.

High stiction can lead to hand fatigue, especially in the case of dermal fillers, where clinicians will often use multiple syringes over the course of a procedure and frequently pause then restart deposition. This action may be repeated dozens, if not over a hundred times a day! In this case, low stiction is vital to reducing fatigue and ensuring the clinician is as accurate with their first syringe as they are with their last.

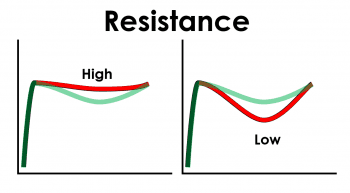

Resistance, a little but not too much

Resistance, referring to the force required to keep the plunger moving while in motion, is a vital part of creating an excellent dermal filler. However, a low resistance does not necessarily translate to a superior product in use or perception. Resistance is a huge factor in enabling deposition of precise quantities of dermal filler. Too much resistance can be a cause of fatigue and frustration for the applicator. Too little resistance, and it may be difficult to inject material in a controlled manner. This makes syringe plunger resistance somewhat of a ‘goldilocks factor’ – the goal should be to create an experience that is not too taxing, but not overtly sensitive to applied pressure.

Resistance, referring to the force required to keep the plunger moving while in motion, is a vital part of creating an excellent dermal filler. However, a low resistance does not necessarily translate to a superior product in use or perception. Resistance is a huge factor in enabling deposition of precise quantities of dermal filler. Too much resistance can be a cause of fatigue and frustration for the applicator. Too little resistance, and it may be difficult to inject material in a controlled manner. This makes syringe plunger resistance somewhat of a ‘goldilocks factor’ – the goal should be to create an experience that is not too taxing, but not overtly sensitive to applied pressure.

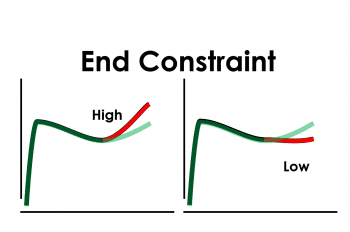

End Constraint

As the syringe empties, the resistance to compression of the pumped material against the end of the syringe barrel becomes more perceptible. This concludes with a sharp increase as the plunger contacts the end of the chamber and the plunger is unable to move further. In the case of a dermal filler, this increase in required force can be detrimental to a product: A clinician expects the syringe to behave the same through out the dispensing process – if the syringe is noticeably harder to pump at different stages throughout the process (with the exception of expected stiction) then that can be construed as a mark of poor quality.

Conclusion

Syringeability is a key property for dermal fillers and indeed, a number of other injectables. Experienced clinicians will build preferences based on how products can help them achieve positive outcomes for their patients – if one product is easier to use than another and helps them achieve the same outcome, then it is obvious which product they will pick. Stiction, resistance and end constraints all come into play to create a dermal filler that is effective, aids in accuracy, is comfortable for the patient and easy to use for the clinician. A syringeability profile, looking at multiple syringes of products across the marketplace can help a to set goals for formulation, market to purchasers and understand an underutilised measurable.

Syringeability is a key property for dermal fillers and indeed, a number of other injectables. Experienced clinicians will build preferences based on how products can help them achieve positive outcomes for their patients – if one product is easier to use than another and helps them achieve the same outcome, then it is obvious which product they will pick. Stiction, resistance and end constraints all come into play to create a dermal filler that is effective, aids in accuracy, is comfortable for the patient and easy to use for the clinician. A syringeability profile, looking at multiple syringes of products across the marketplace can help a to set goals for formulation, market to purchasers and understand an underutilised measurable.

If you would like to discuss a benchmarking study for your injectable, or simple identify key metrics to determine quality please feel welcome to contact us.