Rheological profiling can provide formulators with  a valuable prediction of characteristics relevant to consumers’ experience of a product. In this short study a rheological comparison of two hair conditioners enabled us to quantify the differences in various aspects of handling and application of the products.

a valuable prediction of characteristics relevant to consumers’ experience of a product. In this short study a rheological comparison of two hair conditioners enabled us to quantify the differences in various aspects of handling and application of the products.

The two conditioners were:

- Conditioner A – A “luxury” prestige conditioner with creamy texture and silky “glide”

- Conditioner B – A cheaper brand with a thin, watery texture and perceived poor coating ability

Conditioners can be described as “non-Newtonian, shear-thinning, structured and viscoelastic liquids.” So what does that all mean?

“Non-Newtonian liquids” exhibit a viscosity that is dependent upon the applied shear stress or shear rate. “Shear-thinning” (also termed “pseudoplastic”) behaviour describes the decreasing viscosity with increasing shear, a behaviour commonly observed in solutions and colloidal systems such as suspensions and emulsions. “Structured liquids” possess a delicate soft-solid structure that imparts high viscosity under low stress conditions but that yields to a free-flow liquid when sufficient stress is applied to disrupt this structure. “Viscoelastic liquids” are those that display a degree of elastic response. This can manifest in small deformation situations such as the wobble and bounce observed on handling, or in large deformation situations, such as under significant shearing in mixing, pumping and filling processes.

Shear rate profiling with a high performance rheometer enables us to quantify three useful characteristics of hair conditioners:

Viscosity as a function of shear stress: For identifying and comparing yield stress, the stress required to initiate flow.

Viscosity as a function of shear rate: For understanding resistance to flow across a range of shear conditions, notably those of relevance to application and spreading

Elasticity under shear: For identifying the presence and dominance of elastic behaviour under shear – a useful predictor of lubrication and sensory qualities.

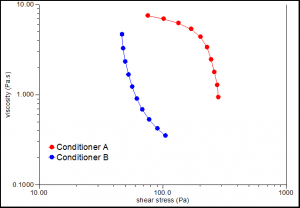

Viscosity/shear stress profiling

When a bottle is inverted gravity applies a downward stress, a component of which acts to push the contents out of the bottle. In order for a product to be easily poured it must have a suitably low viscosity under the application of those stresses. Figure 1 shows the viscosity/shear stress relationships for the two products tested. The yielding behaviour of both can be clearly seen as precipitous drops in viscosity occurring as certain stresses are applied. It is obvious that Conditioner A yields at a significantly higher stresses (around 250 Pa) than Conditioner B (around 50 Pa). This means that B requires around a fifth of the stress that A requires to initiate flow. This low yield stress contributes to the impression of thinness and low quality for Conditioner B.

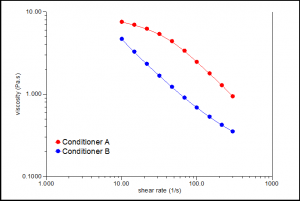

Shear rate profiling for application and texture

Viscosity profiles across a range of shear rates shown in figure 2 demonstrate that, despite the fact that both products are shear-thinning, A maintains a viscosity around three times higher than B at the higher shear rates relevant to application and spreading.

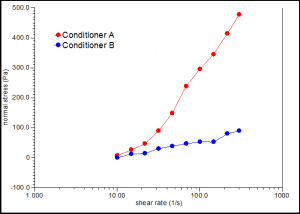

Finally, figure three shows the differences in normal stress generated when shear is applied to both products. Normal stress is a stress generated due to elastic effects under shearing. Shear-thinning materials that display a high normal stress growth tend to exhibit good lubrication. This manifests as the formation of a slippery coating that maintains separation between surfaces, giving rise to the silky glide characteristics of Conditioner A that are absent in Conditioner B.

For further information about these tests, or the range of tests that we offer, please contact our experts today