The viscosity and thermal properties of thermal transfer fluids are vital to characterise when predicting handling and benchmark performance.

Performance additives such as nano-particles, anti-corrosion or anti-freeze can significantly impact base handling and thermal transfer properties, so they must be balanced for the intended application.

With tight control of handling behaviour and thermal performance, it’s possible to design highly specific thermal fluids that meet the exact requirements of your process. Viscosity testing and thermal conductivity testing provides a way to quantify these vital behaviours for formulation design.

Our lab provides the characterisation of both handling properties and thermal properties, providing reliable data for simulations or comparative data for competitor benchmarking.

Contact us for a tour and a chat, or send us your samples for testing

Thermal transfer fluids are primarily designed with three key considerations in mind:

- Handling behaviour: Typically described using viscosity and density

- Thermal transfer performance: Including thermal conductivity and heat capacity

- Performance Additives: Balancing value-add benefits that may change the above properties

Viscosity – Pumping thermal transfer fluids

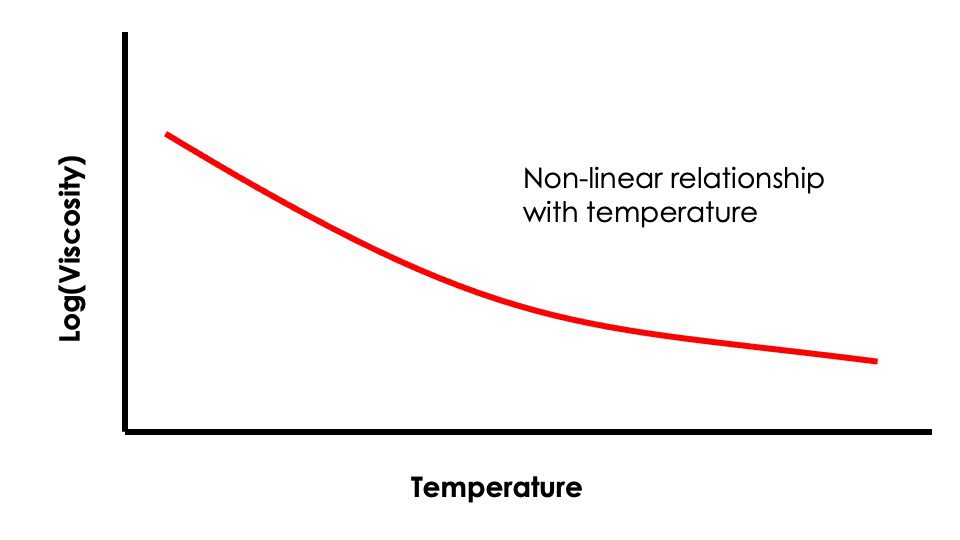

Characterising the flow behaviour of a thermal transfer fluid is vital for assessing pumpability, specifying a pump, designing a fluid transfer system, and modelling heat transfer. We provide accurate viscosity measurements either as a function of shear rate (for non-Newtonian materials) or temperature.

Thermal Conductivity and Heat Capacity Measurements

In addition to ensuring the fluid is pumpable at application temperature, it is vital to ensure thermal transfer efficiency also meets your requirements.

Thermal conductivity is a measure of the ability of a material to conduct thermal energy – thermal insulators will generally have low thermal conductivity values. Heat capacity is another critical metric for thermal transfer fluids.

It indicates the amount of heat required to raise the temperature of a unit volume (volumetric heat capacity) or mass (specific heat capacity) by 1°C.

Benchmarking formulations for performance as heat transfer fluids

Benchmarking formulations for performance as heat transfer fluids

To meet the demands of the intended application, additives may be used to provide specific benefits or to ensure the thermal transfer fluids is capable of meeting requirements in terms of operation temperature, corrosion, food safety or chemical resistance.

While these additives may be vital to enable the use of a thermal fluid for a particular application, they can often complicate handling behaviour or modulate thermal conductivity.

Nanofluids and the addition of nanoparticles to thermal transfer fluids have been recently gaining popularity as the future of thermal transfer fluids due to their improved thermal performance. Nanofluids will generally have more nuanced behaviour and need to deal with suspension stability, non-Newtonian behaviour, interfacial interaction and chemical stability and sensitivity.

Contact us now to discuss how we can help characterise and test the viscosity and thermal properties of your thermal transfer fluid